| Rootes Group “Arrow” series |

1967 Hillman Hunter Saloon

|

| Overview |

| Manufacturer |

Rootes Group

Chrysler Europe |

| Production |

1966–1979 (until 2005 in Iran) |

| Assembly |

Ryton-on-Dunsmore, United Kingdom

Linwood, United Kingdom

Santry, Republic of Ireland

Tehran (Iran Khodro), Iran

Port Melbourne, Australia

Petone and (from 1975) Porirua,New Zealand |

| Designer |

Rex Fleming (overall)

Roy Axe (estate and coupé) |

| Body and chassis |

| Body style |

4-door saloon

5-door estate

2-door coupé

2-door pick-up |

| Related |

See article for list of Arrow marques

Paykan |

| Powertrain |

| Engine |

|

| Transmission |

4 speed manual

4-speed manual + D-type Laycock Overdrive (1966–1972)

4-speed manual + J-type Laycock Overdrive (1972 on)

Borg-Warner 35/65 automatic |

| Dimensions |

| Wheelbase |

98 in (2,489 mm) (saloon) |

| Length |

171 in (4,343 mm) (saloon) |

| Width |

63 in (1,600 mm) (saloon) |

| Height |

56 in (1,422 mm) (saloon) |

| Curb weight |

2,100 lb (953 kg) (saloon) |

| Chronology |

| Predecessor |

Hillman Minx |

| Successor |

none |

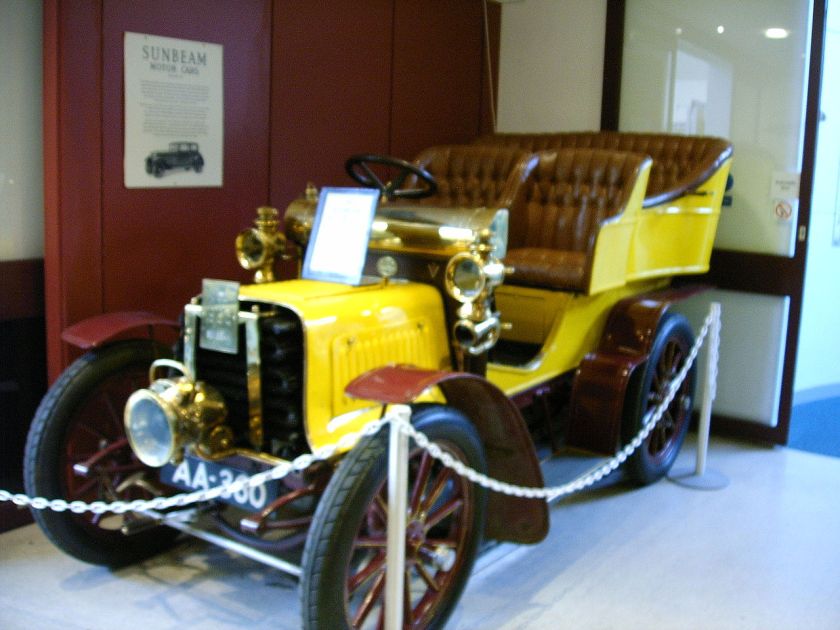

Rootes Arrow was the manufacturer’s name for a range of cars produced under several badge-engineered marques by the Rootes Group (later Chrysler Europe) from 1966 to 1979. It is amongst the last Rootes designs, developed with no influence from future owner Chrysler. The range is sometimes referred to by the name of the most prolific model, the Hillman Hunter.

A substantial number of separate marque and model names applied to this single car platform. Some were given different model names to justify trim differences (Hillman GT, Hillman Estate) and that from time to time all models were sold in some European markets under the Sunbeam marque (Sunbeam Sceptre for instance), and at other times used UK marque/model names. To add complication, Singer Gazelle/Vogue models were also sold in the UK for one season badged as Sunbeams after the Singer brand was withdrawn.

The models sold – not all concurrently – were, alphabetically by marque:

The most prolific model within the Arrow range, the Hillman Hunter, was the Coventry-based company’s major competitor in the medium family car segment. In its 13-year production run, its UK market contemporaries included the Ford Cortina, Morris Marina and Vauxhall Victor, although model positioning within the range meant competition with some larger cars as well, including the Austin 1800.

The Arrow range extended to several body styles: saloon, estate, fastback coupé and a pick-up (sold mainly in South Africa as the Dodge Husky). Depending on the model, they had two doors or four doors. Not all marques were represented in all body styles, with the coupés being reserved for Sunbeam.

Development

The Arrow range was conceived in 1962. Following the Hillman Imp, consideration was given to developing a larger rear-engined car, but this concept was dismissed, and the engineering settled on for the new car was more conventional and closer to the layout of the existing Audax series (which included the previous Hillman Minx).

With cash-strapped Rootes struggling amid continuing engine cooling problems with the Imp, which often resulted in warped cylinder heads, the cautious Arrow broke little new engineering ground. New parts were largely based on tried and tested Rootes components, using a new but strong 5-bearing version of the well-proven 1725 cc overhead valve petrol engine as a starting point which varied in output from 66 bhp (49 kW) to 88 bhp (66 kW) (in the Humber Sceptre). The engine was inclined by a modest 15 degrees, to allow for a lower bonnet line and to enable packaging of the carburettors. This engine was further uprated by specialists Holbay, employing two Weber 40DCOE carburettors to produce 107 bhp (80 kW) for the Sunbeam Rapier H120 and Hillman Hunter GLS. A smaller 1500 cc engine was the standard for manual versions of the Hillman Minx and the Singer Gazelle, and the Hillman Hunter DeLuxe model which succeeded the Minx. Automatic models were all powered by the 1725 cc engine. Particular attention was paid to weight and cost to bring the vehicle in line with its natural competitors, including the Mark 2 Ford Cortina.

For the first time in a Rootes car MacPherson strut suspension featured at the front, with a conventional live axle mounted on leaf springs at the rear. Other firsts for Rootes in the new car were curved side glass and flow-through ventilation.

Manual transmissions were available in four-speed form with an optional Laycock de Normanville overdrive, or Borg-Warner automatic transmission, again as an option. Initially, the Borg Warner Type 35 3-speed automatic was offered, then the Type 45 four-speed automatic became available in 1973.

The handbrake was situated between the driver’s seat and door (i.e. on the driver’s right-hand side for a right-hand drive car) rather than between the front seats. This followed the practice in the ‘Audax’ cars.

The first Arrow model to be launched, the Hillman Hunter, was presented as a replacement for the Hillman Super Minx. The Hunter was lighter than its predecessor and the wheel-base of the new car was actually 2½ inches (6.4 cm) shorter than that of the old, but the length of the passenger cabin was nonetheless increased by moving the engine and the toe-board forwards.

For the first two years there were few changes. However, in May 1968 power assisted brakes were made available as a factory fitted option. Hitherto this possibility had been offered only as a kit for retro-fitting: it was stated that the factory fitted servo-assistance, at a domestic market price slightly below £13, would be cheaper for customers.

A mild facelift in 1970 gave new grilles to the various Hunter trim levels, and some derivatives gained a (then) more fashionable dashboard, exchanging wood for plastic, but the car remained fundamentally the same throughout its life.

A more detailed facelift for 1972 brought a new all-plastic dashboard with deeply hooded round dials (earlier versions had either a strip speedometer or round dials in a flat dashboard for more expensive models like the Vogue), new steering wheel, plastic instead of metal air cleaner, reshaped squarer headlamps in a new grille and some engine tuning changes.

For 1975, bumpers were enlarged and the tail lights were enclosed in a full-width anodised aluminium trim piece.

Following the 1967 acquisition of Rootes by Chrysler, the Arrow derivatives were rationalised until only the Hillman Hunter version was left by 1976. From September 1977 it was re-badged as a Chrysler, which it was to be for the remaining 2 years of its life. Hunter production was switched in 1969 to Rootes’ troubled Imp plant in Linwood, from its original home of Ryton.

Sales were lower after 1975 following the launch of the Chrysler Alpine, a similar sized car but with front-wheel drive and a hatchback bodystyle, at a time when rear-wheel drive saloons still dominated in this sector.

Following the Hillman Avenger‘s move to Linwood in 1976, the very last European Hunters were assembled in the Santry plant, Shanowen Road, Ireland from “complete knock down” (CKD) kits until production ended in 1979 – but no evidence exists to suggest that the Talbot badge was applied to any production Hunter following Chrysler Europe’s 1978 takeover by Peugeot, and the application of that badge to other Chrysler models sold on or after 1 August 1979.

The final Chrysler Hunter was built in September 1979 in Porirua, New Zealand, and was donated to the Southward Museum. In 2000 the Museum sold the car to a private collector.

Models and market positions

As Rootes looked to rationalise the number of platforms and the total engineering cost of their vehicle line-up during the 1960s, they kept alive the many names of the companies they had purchased to maintain product differentation out in the market place. As such, the Arrow was simultaneously aimed at several slightly different market segments, using a range of brand and model names during the car’s 13-year production run.

Hillman

The first models, launched on the domestic market in October 1966 with a 1725 cc engine, were given the Hillman Hunter name with the respected name Hillman Minx (for the cheaper 1496 cc version), following in January 1967. Hillman would remain the British group’s most prolific marque. The Hunter model name was not in fact entirely new for a Rootes-related car, having been used for one year’s production of the Singer SM1500.

Sports models included the Hillman GT, which was based on the Minx trim, but was a model in its own right (not a “Hillman Minx GT” nor “Hillman Hunter GT”). It featured a twin Zenith Stromberg CD150 carburettor version of the 1725 engine developing 94 bhp and Ro-Style wheels. in 1972 came the Hillman Hunter GLS with a specially-tuned twin-Weber-carburettor engine (by Holbay) shared with the Sunbeam Rapier H120 model, as well as close ratio gearbox and quad headlights.

The estate version, announced in April 1967, was originally launched as the “Hillman Estate Car” without either Hunter or Minx badging. It came with a one piece tailgate which was much cheaper to produce than the horizontally split two piece tailgate featured on the car it replaced, but the change nevertheless drew some unfavourable press comment.

The car’s image was boosted when a Hunter driven by Andrew Cowan won the 1968 London-Sydney Marathon rally.

The range was soon simplified with trim levels and varying engine specifications: the Hillman Hunter DeLuxe or DL replaced the Minx and retained the 1496 cc engine; the 1725 cc engine with an iron cylinder head being an option on these entry level models. Above that were the Hunter Super and Hunter GL, both with the higher specification alloy headed engine and two different trim levels. The twin carburettor engined “Hillman Hunter GT” eventually replaced the Hillman GT, and the Holbay-engined GLS was positioned at the top of the range.

For the 1975 Motor Show, a limited edition Hillman Hunter Topaz was produced. This was largely based on the Hunter Super and equipped with overdrive, radio, vinyl roof, Rostyle wheels and a special half cloth upholstery as standard. This car was only available in a unique metallic bronze paint finish. The price was less than that of the standard Hunter Super when fitted with the optional overdrive. A Hillman Break de Chasse was sold in French-speaking markets, based on the Minx specification. (Also offered was a similar Sunbeam Break de Chasse; “break” being a French term for an estate,and the phrase break de chasse translating roughly as shooting-brake.)

Singer

The Singer Vogue and Singer Gazelle were positioned slightly upmarket of the Hillman Hunter and the Minx respectively. Nevertheless, the need to compete on price was evidenced with the announcement of the Singer Vogue estate car. The Vogue saloon was fitted with an alternator, but the Vogue estate, announced in April 1967, was fitted with a dynamo; the manufacturers explained that the change was made to help keep the model’s recommended UK-market selling price below £1,000.

The Singers were short-lived models, retired early in 1970 along with the rest of the Singer range. Briefly following the retirement of the Singer brand, and throughout the model life for principal export markets, the Singer Vogue was badged as a Sunbeam.

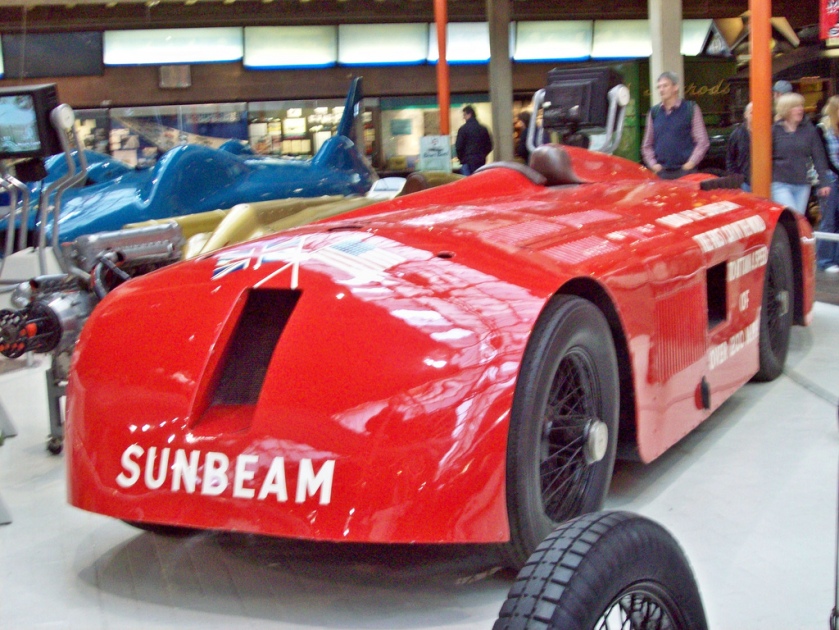

Sunbeam

1974 Sunbeam Rapier fastback coupé in “Grasshopper” green

The single-carburettor Sunbeam Alpine and twin-carburettor Sunbeam Rapier were only sold as fastback coupés, and were marketed with a strong sporting image – although it was eventually the Hillman Hunter which was used in long-distance rallying. The sportiest Sunbeam was the Rapier H120 model, though this shared its specially tuned Holbay engine with the Hillman Hunter GLS.

Sunbeam Arrow, Sunbeam Break de Chasse, Sunbeam Hunter, Sunbeam Minx, Sunbeam Sceptre, and Sunbeam Vogue were used for export markets where the Sunbeam name was more familiar or deemed more likely to succeed. The Sunbeam Arrow name was used in North America. Sunbeam Break de Chasse, Hunter, Vogue, and Minx were offered in some French-speaking markets (where “break” is a term for an estate).

A Sunbeam Sceptre appeared in France and some German-speaking markets (at least), and carried the Humber Sceptre level of specification, as described below. The Sunbeam Vogue was also available in the home (British) market for a short period after the Singer marque was retired in 1970.

Humber

Main article:

Humber SceptreThe Humber Sceptre traded on Humber’s tradition of building luxury cars and was the best-appointed version, with the exception of the similar Sunbeam-branded Sunbeam Sceptre sold in some markets.

The manual-gearbox model featured either the D-type or the later J-type Laycock De Normanville overdrive, with the J-type fitted from chassis numbers L3 onwards starting in July 1972. As with all Arrows, an automatic gearbox was an option. A closer ratio G-type gearbox was fitted to later Sceptres, using the J-type overdrive.

An estate version of the Humber Sceptre was introduced at the London Motor Show in October 1974. It featured a built-in roof rack and a carpeted loading floor protected by metal strips and illuminated by an additional interior light. Washer and wiper were provided for the rear window, a rare feature on UK-market estate cars of the time.

Chrysler

The Hillman Hunter was rebranded as the Chrysler Hunter for the UK market in September 1977, receiving at the same time a four headlight frontal treatment similar to that of the Hunter GLS model and the Humber Sceptre. In order to try to prolong the model life an improved level of equipment included a central console and a voltmeter. The Super version also featured an aluminium-head engine and viscous fan coupling along with reclining seats, a vinyl-covered roof and “simulated wood treatment” for the facia and door sills. By this time, however, Chrysler UK dealers had been selling the French-built Chrysler Alpine for more than two years: more than ten years after the launch of the original Hillman Hunter, the Chrysler Hunter was self-evidently a run-out model, and relatively few were produced. According to How Many Left, only 4 are still on UK roads. It was effectively replaced by the Talbot Solara – a four-door saloon version of the Alpine hatchback – which was launched in April 1980.

Iranian, Australian and New Zealand ranges

Australia

Starting in 1967, Chrysler Australia Ltd assembled the Hillman Hunter from imported CKD packs at their Port Melbourne factory, which they inherited as part of Chrysler’s acquisition of Rootes Australia.

Production commenced in 1967 with 2 models, designated as the HB series: the Arrow (with a trim level corresponding with the home market (United Kingdom) Minx, but with a front bench seat), and the Hunter.

These were replaced by the HC series in 1969. The major changes were adoption of the UK face-lifted Hunter radiator grille and rectangular headlights, and the renaming of the Arrow as the Hunter, retaining the Arrow’s trim specification and bench seat. At the same time came the introduction of the Safari estate (known in Australia as a station wagon.) The Safari name was also used to identify the Australian Chrysler Valiant estate model. There was also the addition of two, new, more upmarket saloon variants: the Hunter Royal (corresponding in trim level with the UK Singer Vogue, but retaining the Hunter plastic moulded dashboard, with simulated wood trim), and the Hunter GT, which corresponded with the UK Humber Sceptre in trim level, but with the standard Hunter grille. These cars featured trim parts from various UK models, including UK Humber Sceptre bonnet ornaments.

The Safari estate was a popular seller, particularly as the competing Holden Torana was not available as an estate.

In 1971, the Australian version of the Hunter was face-lifted again, with the introduction of the HE series. Marketing of the car, plus its rear badges, referred to it as the Hunter, rather than a Hillman.

The facelift involved a change to the radiator grille, with new and smaller rectangular headlights. Also, the appearance of the rear of the car was changed with a flush trim panel under the boot lid and new twin-lens tail lights. Depending on the model, this panel was painted in the body colour or a matte grey; this facelift was unique to Australia.

Inside, the HE models received a new collapsible steering column, with the Valiant’s steering wheel.

The model range was later modified again: a new cut price performance version called the Hustler was introduced. This was similar in concept and execution to the UK Hillman GT – a sparsely trimmed car with high performance.

The Hunter GT was renamed the Hunter Royal 660. Outside, this car gained Rostyle wheels. Inside, the car was trimmed in the same “buffalo grain” textured vinyl, which also was to be found in the VG series luxury Valiant, the Regal 770.

These cars sold steadily, but they became overshadowed when Chrysler Australia commenced assembly of the Mitsubishi Galant in 1972. By this time, the Mitsubishi was a conspicuously more modern car, and by 1973, the Hunter was phased out, and became the last Rootes car to have been marketed in Australia. Chrysler Australia then closed the former Rootes factory, focusing Australian production at their Tonsley Park plant in Adelaide.

New Zealand

New Zealand importer and CKD assembler Todd Motors also created its own unique versions of the Arrow line. The single 1967 launch version (1725 cc aluminium head engine with four-speed manual transmission or three-speed Borg Warner 35 automatic transmission with twin fron seats) was almost identical to its UK counterpart but Todd started to use its own upholstery designs from the 1969 rectangular headlight update. For 1970, it added a silver rear trim panel to the Hunter and introduced the estate although this had a lower specification than the saloon – an iron head 1725 cc engine, no automatic option, simpler dashboard trim (no locking glovebox), painted rather than bright metal door window trim and fixed rather than opening front quarter-lights.

Todd’s also offered a Singer Vogue saloon with a 1725 cc engine and a more upmarket wood veneer dashboard from 1967–71 when it was replaced by the Hunter GL.

The range was given a unique-to-NZ update early in 1971: the iron head “deluxe” estate (never badged as such) was almost unchanged apart from the side “Hunter” badges moving from the front doors to the front guards and revised seat and door trim patterns, and the door tops switched from black to the same colour as the seats. The alloy headed “super” saloon got these changes plus a spray-on black, instead of silver, tail panel — the texture of this changed from textured fake vinyl to a matte black over the year’s run. Initially the cars were offered with tan, red, blue or black upholstery with the dash painted to match but after a few months, Todd’s switched to a new type of vinyl with different texture for their Avenger, Hunter and Valiant lines and the blue option was dropped and the dashboards reverted to black paint. By now the equivalent Super model in the UK had seen its specification reduced to the iron head engine, no bumper over-riders, less exterior bright metal detailing and fixed front quarterlights — so the New Zealand version was unique.

The range’s first major facelift for 1972 brought an uprated motor with new carburettor and ignition tuning, re-profiled camshaft and a plastic air cleaner housing (these models were always harder to keep in tune than their predecessors), smaller, squarer headlamps, a new dashboard with deeply hooded round dials (the Hunters had strip speedometers previously), high-backed front seats, and a revised silver trim panel surrounding the tail lights.

Todds also added a new “GL” model, replacing the Singer Vogue, that initially had little to distinguish it (and justify a higher price) apart from wooden dashboard and door inserts, the same different trim patterns from the old Vogue and standard reversing lights. In 1973 Todds created another completely unique model by updating the GL with the four-headlight nose from the upmarket Humber Sceptre (a rare UK-assembled import) and altering the tail with a new silver strip below the tail lights, incorporating the reversing lights. These changes gave the GL a much more distinctive appearance front and rear.

By the mid-70s, the Hunter was an old model and under siege from newer Japanese rivals. Todd’s Hunters adopted the larger bumpers and new grille introduced for 1975 in the UK but the range was eventually rationalised into a single Super saloon model with the four-headlight front end and “wood” dashboard inserts (by then it was synthetic wood rather than the real material used originally). The final updates included standard cigarette lighter and heater control illumination.

Around 1975, the optional automatic was uprated from the three-speed Borg Warner 35 to the new, four-speed 45 but there were supply problems and Todds reverted to the 35 three-speed for several assembly runs of the automatic versions.

As in Australia, though six years later, Mitsubishis from Japan sounded the Hunter’s death knell. After beginning with CKD assembly of a single Galant coupé model in 1972, Todds had added the Lancer saloon in 1975 and launched its first mid-size Mitsubishi Galant Sigma saloon line in 1977, effectively replacing the Hunter. The far more modern, better equipped “Mitsis” were pricier, and the Hunter still had its fans and lingered on until 1979, when it was axed in the UK and Todd’s built the last Chrysler-badged version anywhere.

The Hunter’s other claim to Kiwi fame was being the first CKD model line to pass the 30,000-unit mark during its 12-year run.

Iranian Paykan

In 1966, Iran National (now Iran Khodro) of Iran began to assemble Hillman Hunters from CKD kits, after a deal was struck between the Rootes Group and Iran National’s director, Mahmoud Khayami. The resulting Paykan (Persian for arrow) saloon, pick-up and taxi models became known as Iran’s national car.

Earlier versions used the Hunter 1725 cc engine, but later kits were shipped with the Avenger’s 1600 cc engine mated to the Arrow range 4-speed gearbox via a special bell-housing. Later, they were all equipped with a 5-speed gearbox. The engine was upgraded to a Multi Point Electronic Fuel Injection made by Sagem Company. Also the Spark distributor was replaced with ECU Controlled Spark Coils. The differential was also upgraded to a more compatible version to Avenger Engine.

Full local production began in 1985, after the original British production lines were closed. The new owner in Britain, Peugeot, established a new contract whereby Iran Khodro would manufacture the Paykan with the same body panels but Peugeot 504 engines and suspension, for six more years. This deal has a similarity to one in South Africa, where Hunters were once built with locally made Peugeot 404 engines (from which the 504 units evolved) to meet strict local-content laws applicable in the late 1960s.

The Paykan saloon ceased production in May 2005, to be replaced by the Peugeot RD, based on the Peugeot 405 platform. The Bardo 1600i, the pick-up version of the Paykan is still in production (2012) (Although they do not achieve the required standards like having ABS and Airbag). The production rights for the Paykan have now been acquired by the government of Sudan, and production of the Paykan is expected to restart.

-

-

Paykan gathering in Northen Tehran

-

One of the last Paykans to be produced in Iran

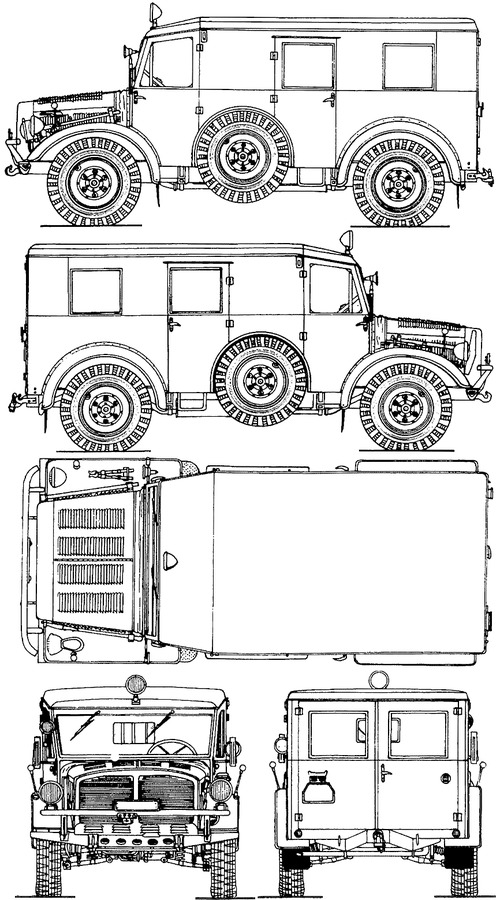

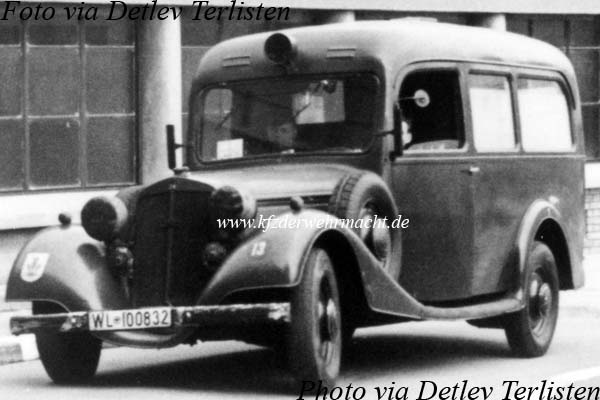

Hanomag + Hanomag Henschel Ambulances

Hanomag + Hanomag Henschel Ambulances

Hino Ambulance Paramedic Resque Unit LY3391

Hino Ambulance Paramedic Resque Unit LY3391

HONDA Ambulances and HONDA Quick Responder Motor Units

HONDA Ambulances and HONDA Quick Responder Motor Units Hudson Ambulances and Hearses since 1922

Hudson Ambulances and Hearses since 1922

Humber Ambulances and Hearses since 1933

Humber Ambulances and Hearses since 1933

HUMMER + HUMVEE Ambulance and Hearses

HUMMER + HUMVEE Ambulance and Hearses

Hyundai Ambulance and Quick Responder units

Hyundai Ambulance and Quick Responder units Golf Ambulance

Golf Ambulance

golfkartambulances

golfkartambulances

Helicopter Ambulances

Helicopter Ambulances

Holden Ambulances and Hearses

Holden Ambulances and Hearses