VOLKSWAGEN cars – vans

VW

Volkswagen

|

|

|

| Marque | |

| Industry | Automotive |

| Founded | 28 May 1937 |

| Founder | German Labor Front (Deutsche Arbeitsfront, DAF) Adolf Hitler |

| Headquarters | Wolfsburg, Germany |

|

Area served

|

Worldwide |

|

Key people

|

Herbert Diess (Chairman of the Board of Management of the Volkswagen Passenger Cars brand) |

| Products | Automobiles Vans |

|

Production output

|

|

| Revenue | |

|

Number of employees

|

626,715 (end of 2016) |

| Parent | Volkswagen Group |

| Website | volkswagen.com |

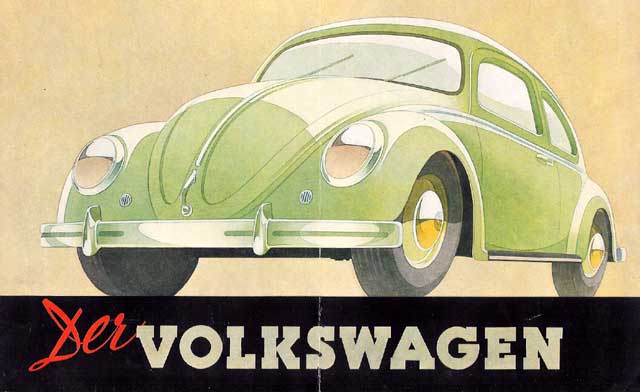

Volkswagen (German pronunciation: [ˈfɔlksˌvaːɡn̩] (![]() listen)), shortened to VW, is a German automaker founded on 28 May 1937 by the German Labour Front under Adolf Hitler and headquartered in Wolfsburg. It is the flagship marque of the Volkswagen Group, the largest automaker by worldwide sales in 2016.

listen)), shortened to VW, is a German automaker founded on 28 May 1937 by the German Labour Front under Adolf Hitler and headquartered in Wolfsburg. It is the flagship marque of the Volkswagen Group, the largest automaker by worldwide sales in 2016.

Volkswagen is German for “people’s car”, and the company’s current international advertising slogan is just “Volkswagen”. American English pronunciation is approximately “volks wagon” (![]() listen(help·info)).

listen(help·info)).

History

1932–1938: People’s Car project

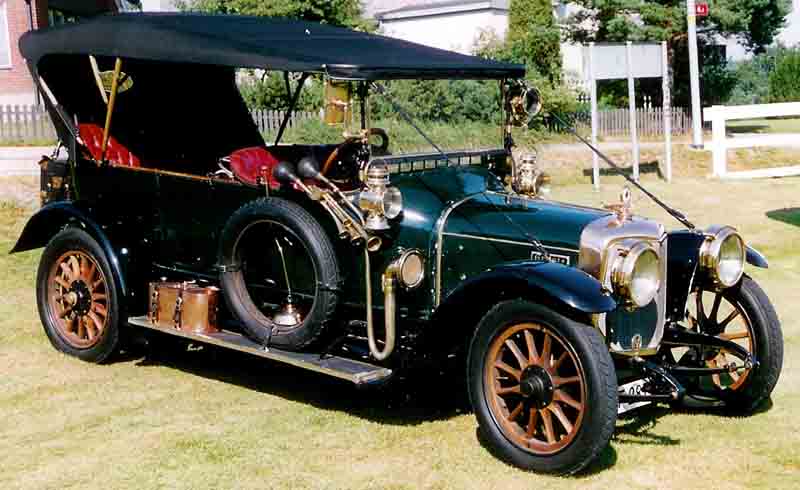

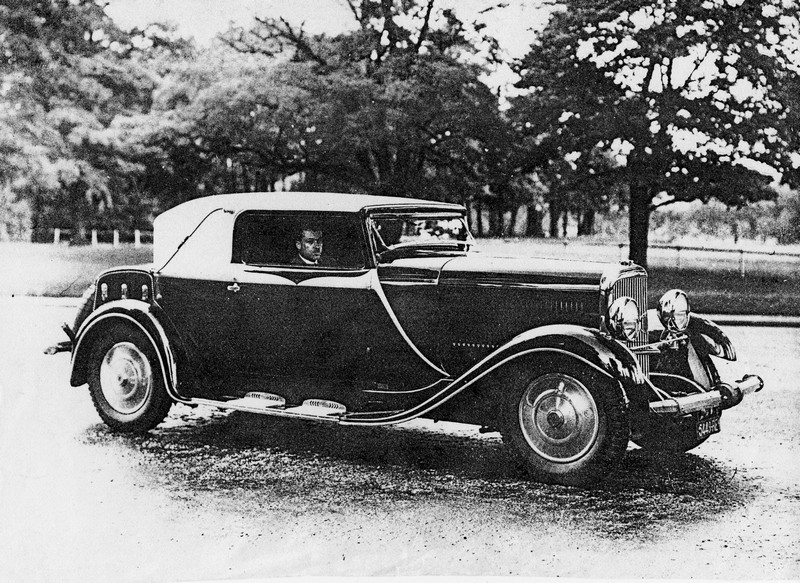

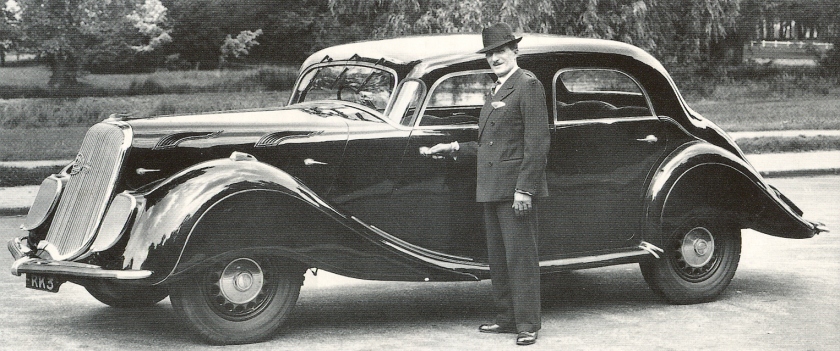

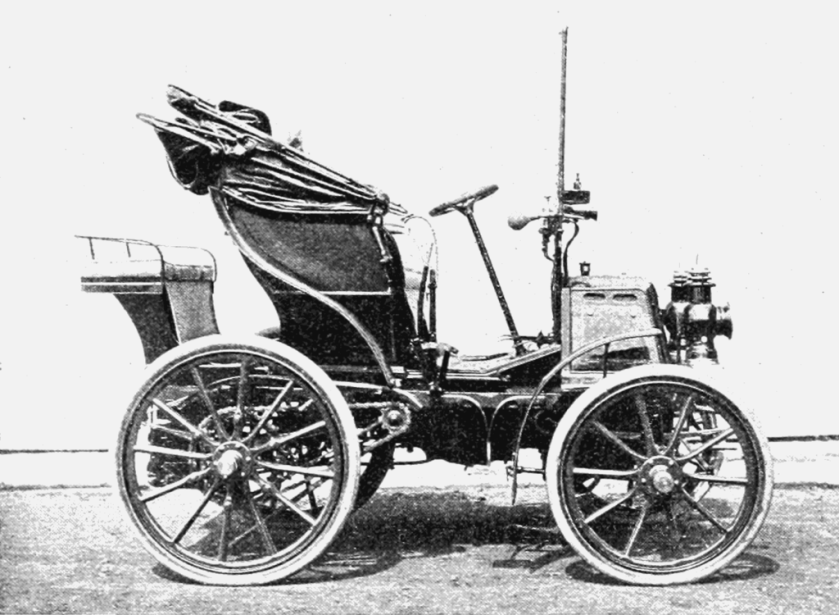

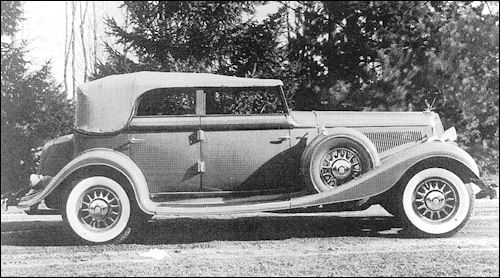

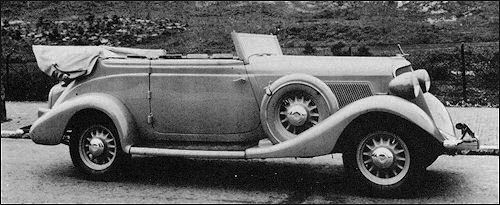

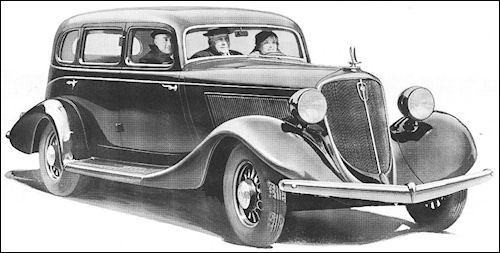

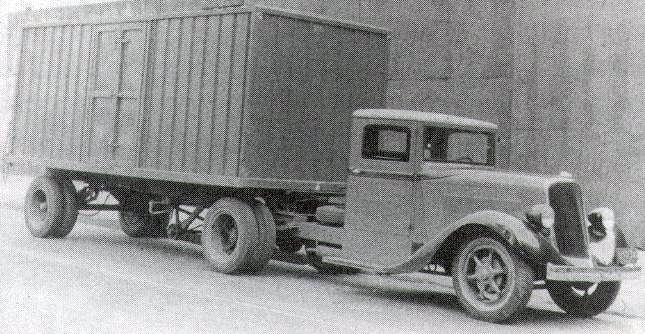

Volkswagen was originally established in 1932 by the German Labour Front (Deutsche Arbeitsfront) in Berlin. In the early 1930s, the German auto industry was still largely composed of luxury models, and the average German could rarely afford anything more than a motorcycle. As a result, only one German out of 50 owned a car. Seeking a potential new market, some car makers began independent “people’s car” projects – the

Steyr 55, and

Hanomag 1.3L, among others.

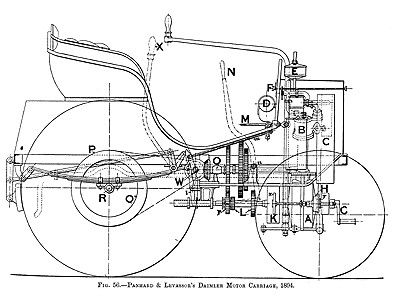

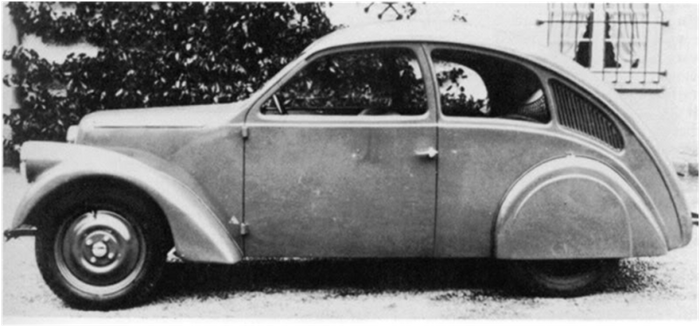

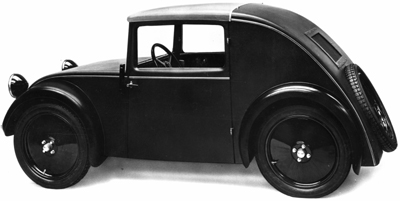

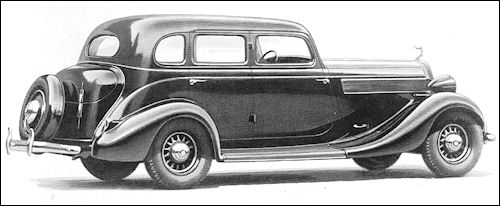

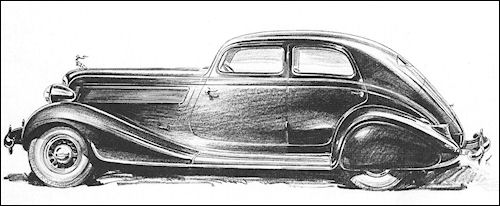

The trend was not new, as Béla Barényi is credited with having conceived the basic design in the mid-1920s. Josef Ganz developed the Standard Superior (going as far as advertising it as the “German Volkswagen”). In Germany, the company Hanomag mass-produced the

2/10 PS “Kommissbrot”, a small, cheap rear engined car, from 1925 to 1928. Also, in Czechoslovakia, the Hans Ledwinka‘s penned

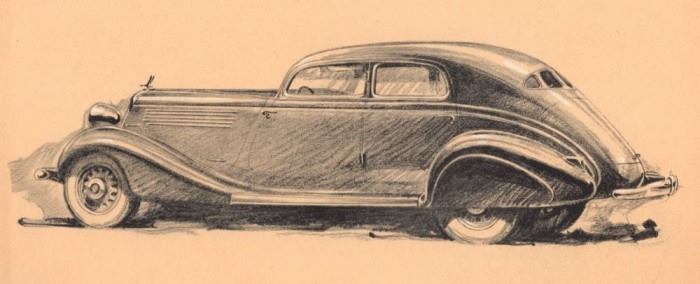

Tatra T77, a very popular car amongst the German elite, was becoming smaller and more affordable at each revision. Ferdinand Porsche, a well-known designer for high-end vehicles and race cars, had been trying for years to get a manufacturer interested in a small car suitable for a family. He felt the small cars at the time were just stripped down big cars. Instead he built a car he called the “Volksauto” from the ground up in 1933, using many of the ideas floating around at the time and several of his own, putting together a car with an air-cooled rear engine, torsion bar suspension, and a “beetle” shape, the front hood rounded for better aerodynamics (necessary as it had a small engine).

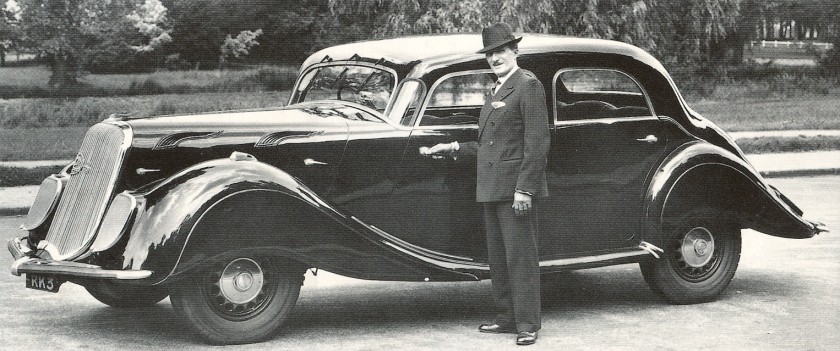

In 1934, with many of the above projects still in development or early stages of production, Adolf Hitler became involved, ordering the production of a basic vehicle capable of transporting two adults and three children at 100 km/h (62 mph). He wanted all German citizens to have access to cars. The “People’s Car” would be available to citizens of the Third Reich through a savings plan at 990 Reichsmark ($396 in 1930s U.S. dollars)—about the price of a small motorcycle (the average income being around 32 RM a week).

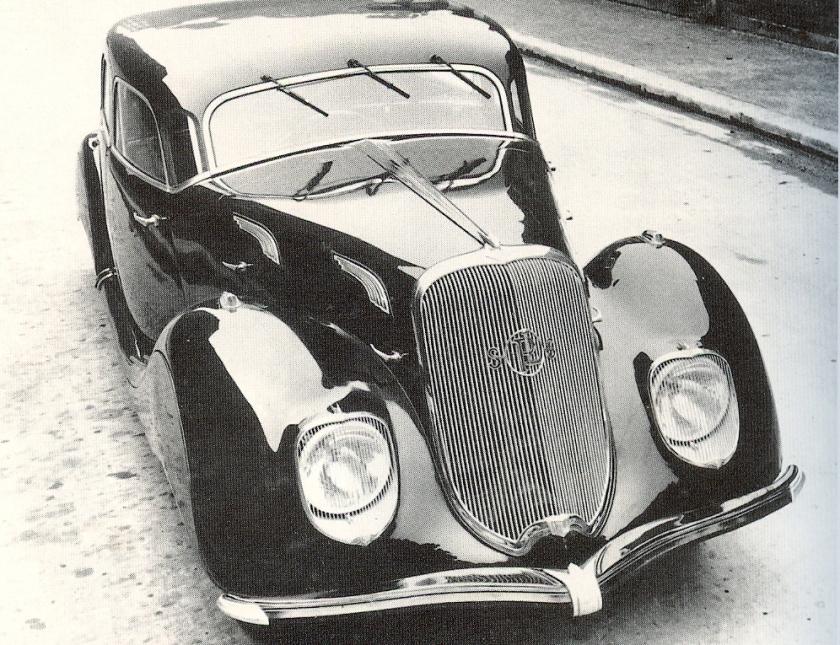

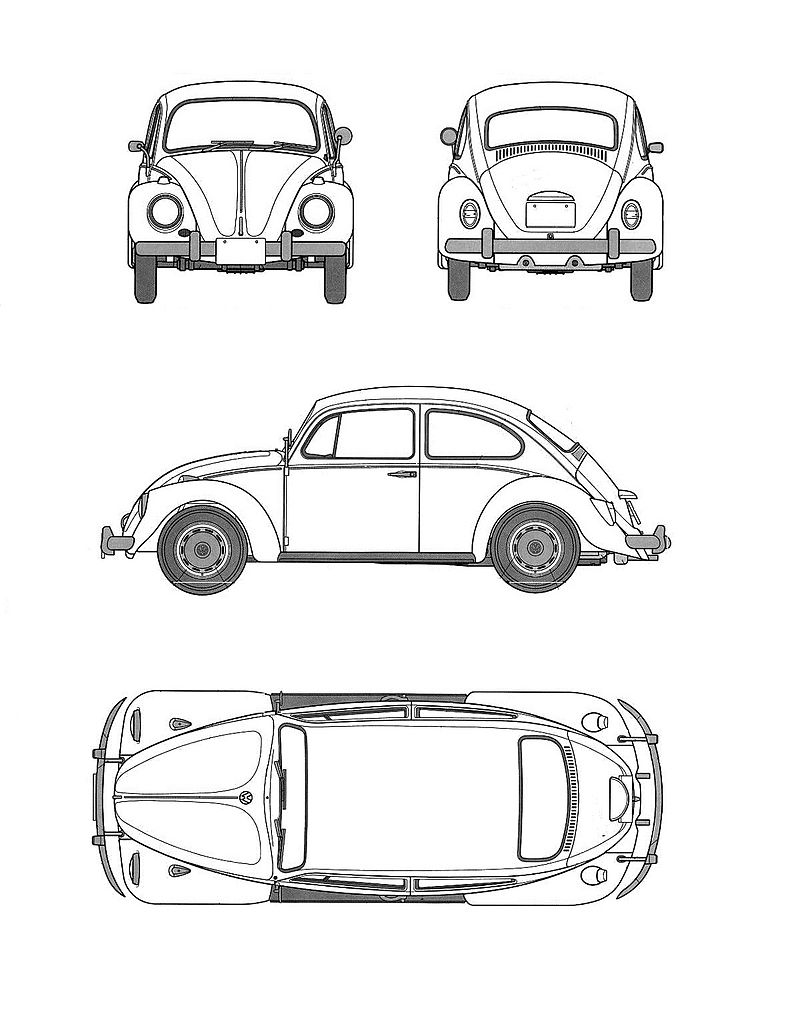

1936 Volkswagen Beetle Type 60 V3 Prototype

Despite heavy lobbying in favor of one of the existing projects, it soon became apparent that private industry could not turn out a car for only 990 RM. Thus, Hitler chose to sponsor an all-new, state-owned factory using Ferdinand Porsche’s design (with some of Hitler’s design constraints, including an air-cooled engine so nothing could freeze). The intention was that ordinary Germans would buy the car by means of a savings scheme (“Fünf Mark die Woche musst du sparen, willst du im eigenen Wagen fahren” – “Five marks a week you must put aside, if you want to drive your own car“), which around 336,000 people eventually paid into. However, the entire project was financially unsound, and only the Nazi party made it possible to provide funding.

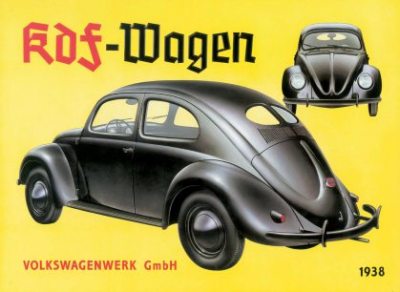

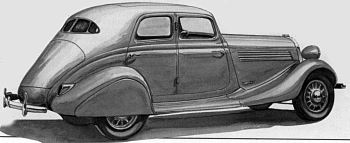

Prototypes of the car called the “KdF-Wagen” (German: Kraft durch Freude – “Strength through Joy”), appeared from 1938 onwards (the first cars had been produced in Stuttgart). The car already had its distinctive round shape and air-cooled, flat-four, rear-mounted engine. The VW car was just one of many KdF programs, which included things such as tours and outings. The prefix Volks— (“People’s”) was not just applied to cars, but also to other products in Germany; the “Volksempfänger” radio receiver for instance.

1937-5-28 Hitler and Ferdinand Porsche are looking at the prototype of VW Beetle on birthday VW

On 28 May 1937 The birthday of Volkswagen, Gesellschaft zur Vorbereitung des Deutschen Volkswagens mbH (“Company for the Preparation of the German Volkswagen Ltd.”), or Gezuvor for short, was established by the Deutsche Arbeitsfront in Berlin. More than a year later, on 16 September 1938, it was renamed to Volkswagenwerk GmbH.

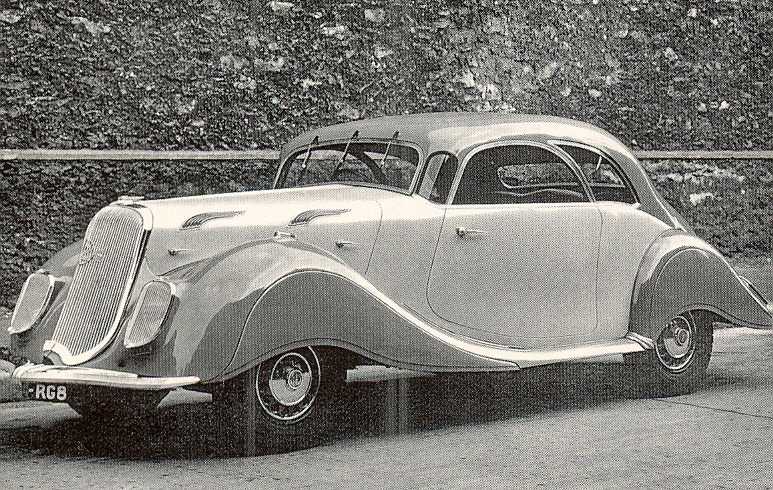

Erwin Komenda, the longstanding Auto Union chief designer, part of Ferdinand Porsche’s hand-picked team, developed the car body of

1939 vw proto 01

the prototype, which was recognizably the Beetle known today. It was one of the first cars designed with the aid of a wind tunnel—a method used for German aircraft design since the early 1920s. The car designs were put through rigorous tests, and achieved a record-breaking million miles of testing before being deemed finished.

http://time.com/3877191/volkswagen-photos-from-the-wolfsburg-factory-1951/

The construction of the new factory started in May 1938 in the new town of “Stadt des KdF-Wagens” (modern-day Wolfsburg), which had been purpose-built for the factory workers. This factory had only produced a handful of cars by the time war started in 1939. None were actually delivered to any holder of the completed saving stamp books, though one Type 1 Cabriolet was presented to Hitler on 20 April 1944 (his 55th birthday).

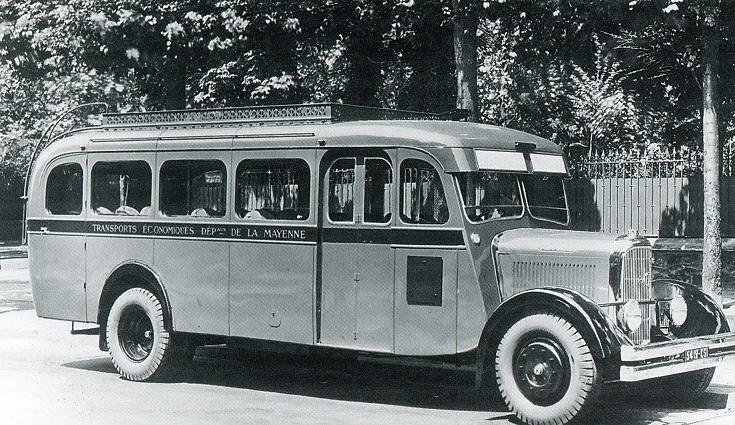

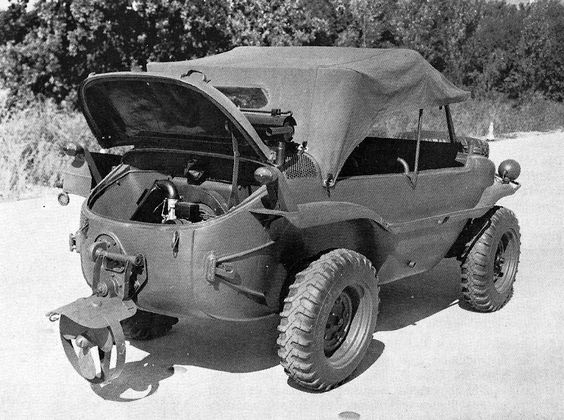

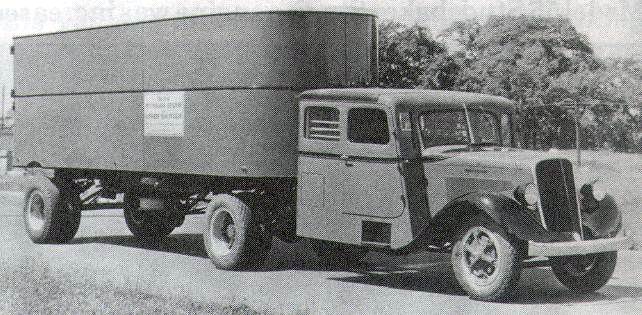

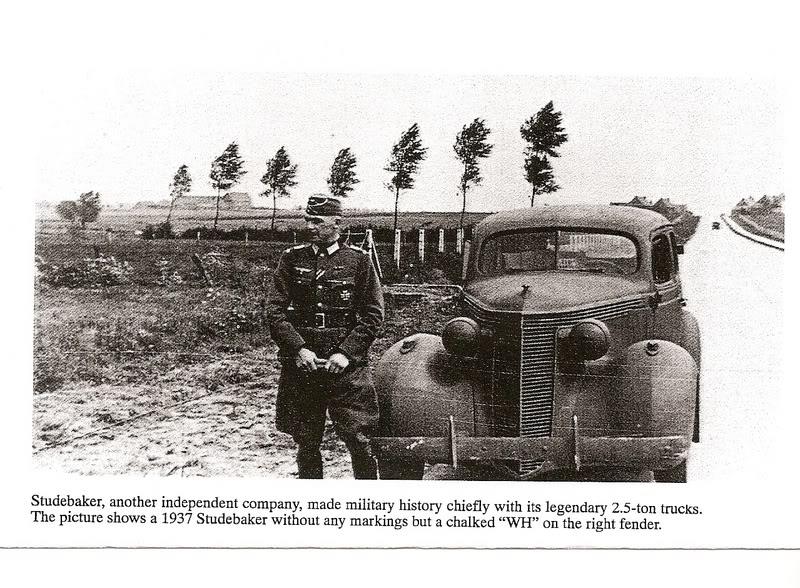

War changed production to military vehicles—

the Type 82 Kübelwagen (“Bucket car”) utility vehicle (VW’s most common wartime model), and

the amphibious Schwimmwagen—manufactured for German forces. As was common with much of the production in Nazi Germany during the war, slave labor was utilized in the Volkswagen plant, e.g. from Arbeitsdorf concentration camp. The company would admit in 1998 that it used 15,000 slaves during the war effort. German historians estimated that 80% of Volkswagen’s wartime workforce was slave labor. Many of the slaves were reported to have been supplied from the concentration camps upon request from plant managers. A lawsuit was filed in 1998 by survivors for restitution for the forced labor. Volkswagen would set up a voluntary restitution fund.

1945–1948: British Army intervention, unclear future

The company owes its post-war existence largely to one man, War-time British Army officer Major Ivan Hirst, REME. In April 1945, KdF-Stadt and its heavily bombed factory were captured by the Americans, and subsequently handed over to the British, within whose occupation zone the town and factory fell. The factories were placed under the control of Saddleworth-born Hirst, by then a civilian Military Governor with the occupying forces. At first, one plan was to use it for military vehicle maintenance, and possibly dismantle and ship it to Britain. Since it had been used for military production, (though not of KdF-Wagens) and had been in Hirst’s words, a “political animal” rather than a commercial enterprise — technically making it liable for destruction under the terms of the Potsdam Agreement — the equipment could have been salvaged as war reparations. Allied dismantling policy changed in late 1946 to mid-1947, though heavy industry continued to be dismantled until 1951.

One of the factory’s War-time ‘KdF-Wagen’ cars had been taken to the factory for repairs and abandoned there. Hirst had it repainted green and demonstrated it to British Army headquarters. Short of light transport, in September 1945 the British Army was persuaded to place a vital order for 20,000 cars. However, production facilities had been massively disrupted, there was a refugee crisis at and around the factory and some parts (such as carburetors) were unavailable. With striking humanity and great engineering and management ingenuity, Hirst and his German assistant Heinrich Nordhoff (who went on to run the Wolfsburg facility after Military Government ended in 1949) helped to stabilize the acute social situation while simultaneously re-establishing production. Hirst, for example, used his fine engineering experience to arrange the manufacture of carburetors, the original producers being effectively ‘lost’ in the Russian zone. The first few hundred cars went to personnel from the occupying forces, and to the German Post Office. Some British Service personnel were allowed to take their Beetles back to the United Kingdom when they were demobilised.

In 1986, Hirst explained how it was commonly misunderstood that he had run Wolfsburg as a British Army Major. The defeated German staff, he said, were initially sullen and unresponsive, having been conditioned by many years of Nazism and they were sometimes unresponsive to orders. At Nordhoff’s suggestion, he sent back to England for his officer’s uniform and from then on, had no difficulty in having his instructions followed. Hirst can be seen photographed at Wolfsburg in his uniform, although he was not actually a soldier at the time but a civilian member of the Military Government. The title of ‘Major’ was sometimes used by someone who had left the Army as a courtesy title. In fact, Hirst chose not to do so.

The post-war Industrial plans for Germany set out rules that governed which industries Germany was allowed to retain. These rules set German car production at a maximum of 10% of 1936 car production. By 1946, the factory produced 1,000 cars a month—a remarkable feat considering it was still in disrepair. Owing to roof and window damage, production had to stop when it rained, and the company had to barter new vehicles for steel for production.

The car and its town changed their Second World War-era names to “Volkswagen” and “Wolfsburg” respectively, and production increased. It was still unclear what was to become of the factory. It was offered to representatives from the American, Australian, British, and French motor industries. Famously, all rejected it. After an inspection of the plant, Sir William Rootes, head of the British Rootes Group, told Hirst the project would fail within two years, and that the car “…is quite unattractive to the average motorcar buyer, is too ugly and too noisy … If you think you’re going to build cars in this place, you’re a bloody fool, young man.” The official report said “To build the car commercially would be a completely uneconomic enterprise.” In an ironic twist of fate, Volkswagen manufactured a locally built version of Rootes’s Hillman Avenger in Argentina in the 1980s, long after Rootes had gone bankrupt at the hands of Chrysler in 1978—the Beetle outliving the Avenger by over 30 years.

Ford representatives were equally critical. In March 1948, the British offered the Volkswagen company to Ford, free of charge. Henry Ford II, the son of Edsel Ford, traveled to West Germany for discussions. Heinz Nordhoff was also present, and Ernest Breech, chairman of the board for Ford Motor Company. Henry Ford II looked to Ernest Breech for his opinion, and Breech said, “Mr. Ford, I don’t think what we’re being offered here is worth a dime!” Ford passed on the offer, leaving Volkswagen to rebuild itself under Nordhoff’s leadership.

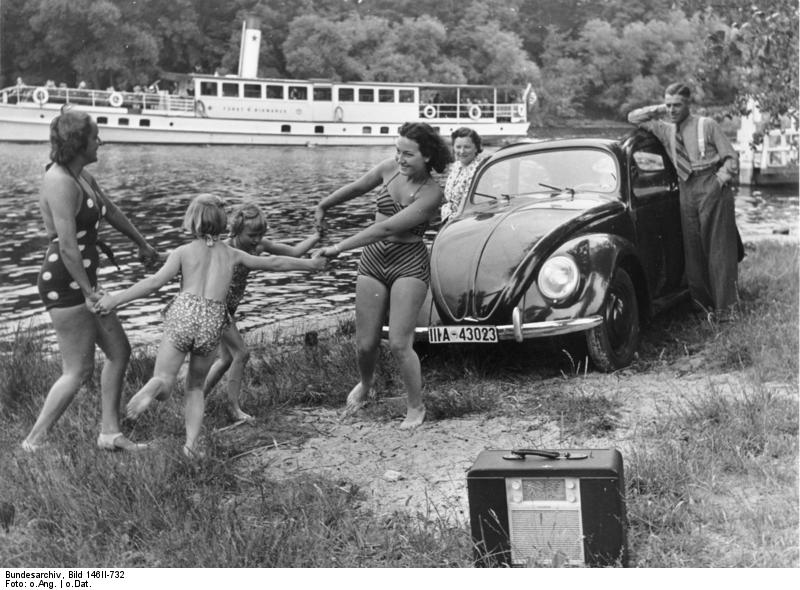

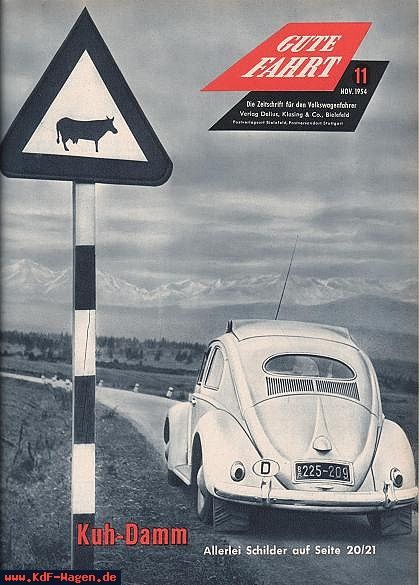

1948–1961: Icon of post war West Germany

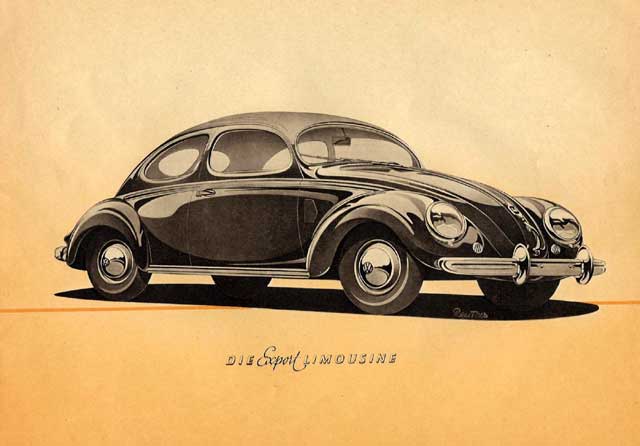

1949 Volkswagen “split rear window” Sedan

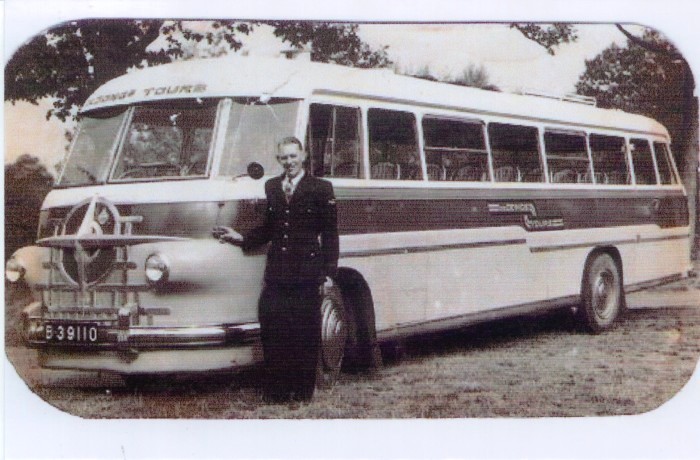

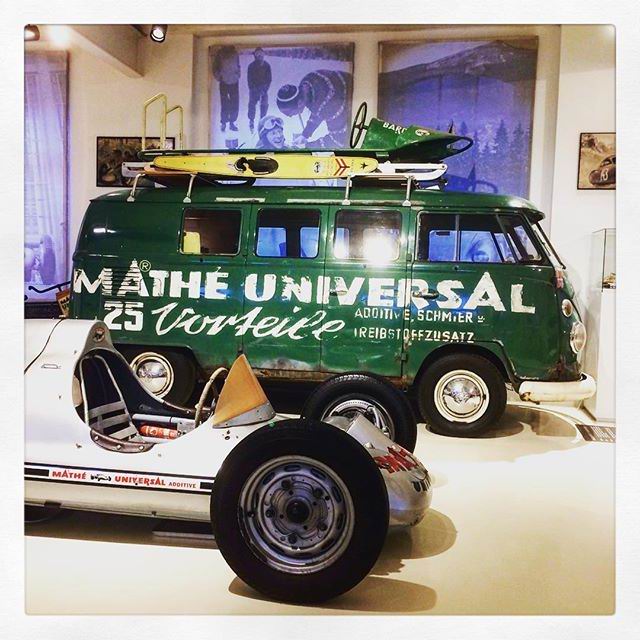

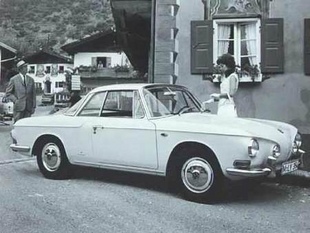

1949 Volkswagen “split rear window” SedanFrom 1948, Volkswagen became an important element, symbolically and economically, of West German regeneration. Heinrich Nordhoff (1899–1968), a former senior manager at Opel who had overseen civilian and military vehicle production in the 1930s and 1940s, was recruited to run the factory in 1948. In 1949, Major Hirst left the company—now re-formed as a trust controlled by the West German government and government of the State of Lower Saxony. The “Beetle” sedan or “peoples’ car” Volkswagen is the Type 1. Apart from the introduction of

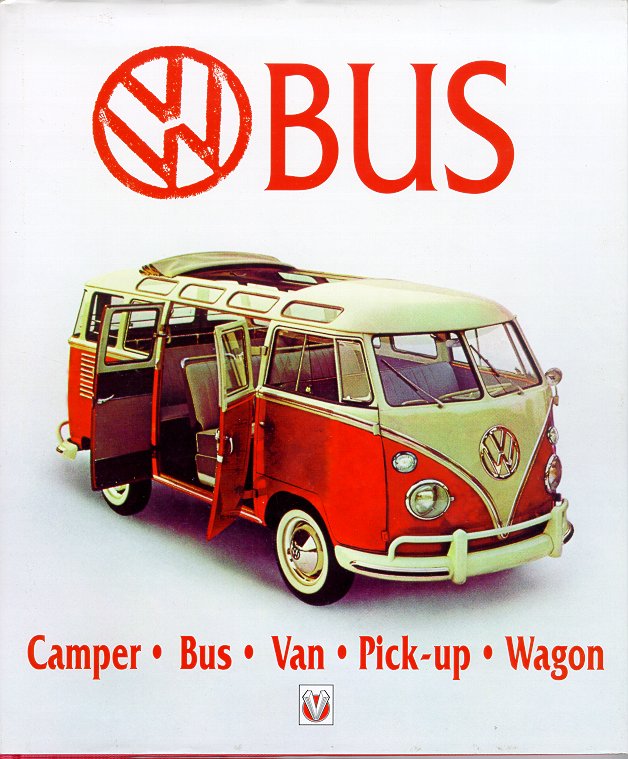

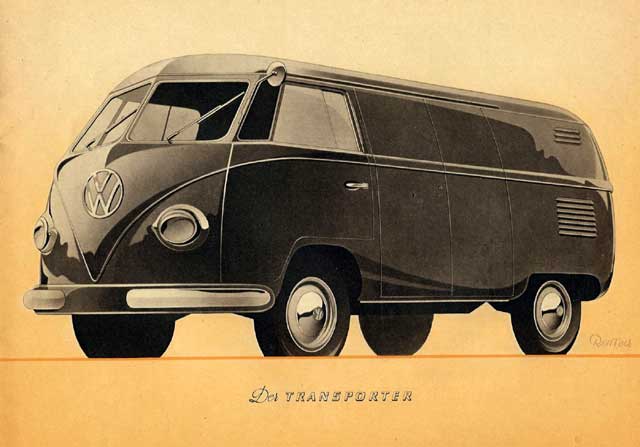

the Volkswagen Type 2commercial vehicle (van, pick-up and camper), and

the VW Karmann Ghia sports car, Nordhoff pursued the one-model policy until shortly before his death in 1968.

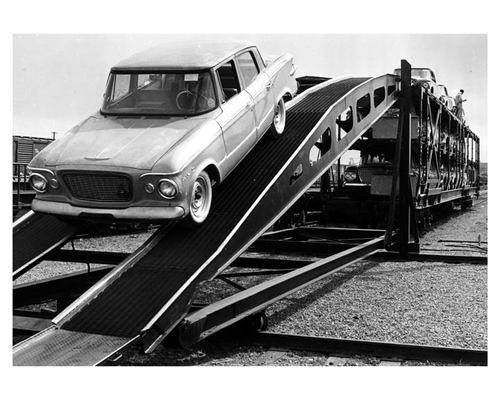

Volkswagens were first exhibited and sold in the United States in 1949, but sold only two units in America that first year. On entry to the U.S. market, the VW was briefly sold as a Victory Wagon. Volkswagen of America was formed in April 1955 to standardise sales and service in the United States. Production of the Type 1 Volkswagen Beetle increased dramatically over the years, the total reaching one million in 1955.

The UK’s first official Volkswagen Importer, Colborne Garages of Ripley, Surrey, started with parts for the models brought home by soldiers returning from Germany.

Canadian Motors, Limited brought in Canada’s first shipment of Volkswagens on 10 July 1952 (shipping order 143075). The order consisted of 12 vehicles, (3) model 11C, a black, green, and sandcolor (3) 11GS, a chestnut brown and two azure blue, (2) 24A-M51 in red, (1)21A in blue, (1) 23A in blue, (1) 22A beige color, and one ambulance. Volkswagens were seen in Canada for the first time at the Canadian National Exhibition in August 1952 and were accepted enthusiastically. (At least one Type 2 bus from this order still exists, and is currently in France undergoing restoration). The first shipment for Volkswagen Canada reached Toronto in early December 1952. (At least one Type 1 from this first shipment still exists, and was driven on a nationwide tour for Volkswagen Canada’s 60th year of business festivities in 2012).

By 1955, sales were on a basis that warranted the building of the Volkswagen plant on a 32-acre (130,000 m2) site on Scarboro’s Golden Mile. To this, a 60,000-square-foot (5,600 m2) building with administration, showrooms, service, repairs and parts was built in 1957, with storage for $4,000,000 of parts.

In 1959, VW started production at a plant near São Paulo in Brazil. Volkswagen do Brasil was accused of spying on workers during the time of the military dictatorship in the 1970´s and informing police on oppositional activities. In 1976, mass arrests occurred and some VW employees were tortured. In 1979, Brazilian VW workers traveled to Wolfsburg to inform the CEO in person. In 2015, activists and former VW employees in Brazil spoke out in public accused the company´s silence about persecution of its workers. In fall 2016, VW commissioned an expert review of the situation due end of 2017.

On 22 August 1960, Volkswagenwerk GmbH was renamed to Volkswagenwerk AG.

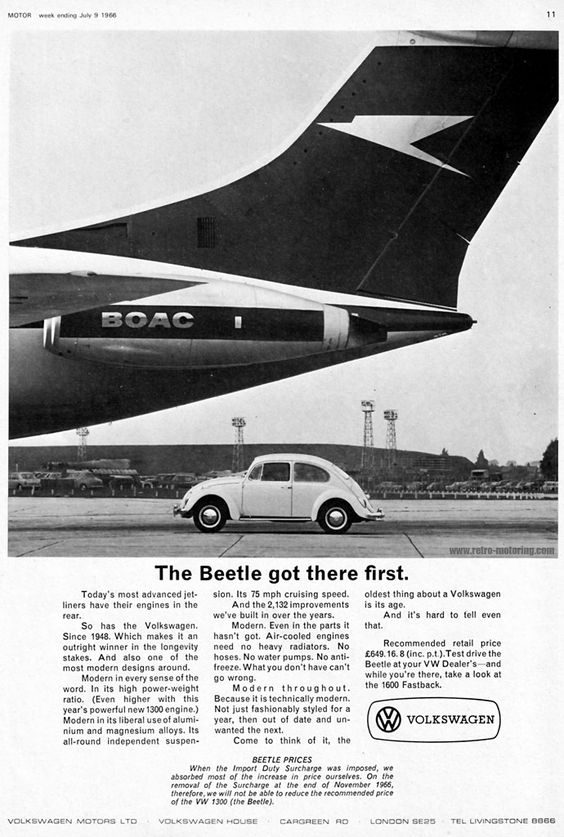

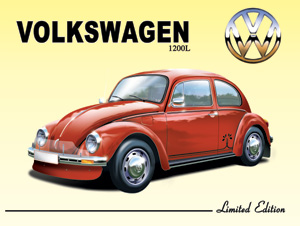

Sales soared, throughout the 1960s, peaking at the end of the decade, thanks in part to the famous advertising campaigns by New York advertising agency Doyle, Dane Bernbach. Led by art director Helmut Krone, and copywriters Julian Koenig and Bob Levinson, Volkswagen advertisements became as popular as the car, using crisp layouts and witty copy to lure the younger, sophisticated consumers with whom the car became associated. Even though it was almost universally known as the Beetle (or the Bug), it was never officially labelled as such by the manufacturer, instead referred to as the Type 1.

Although the car was becoming outdated, during the 1960s and early 1970s, American exports, innovative advertising, and a growing reputation for reliability helped production figures surpass the levels of the previous record holder, the Ford Model T. On 17 February 1972 the 15,007,034th Beetle was sold. Volkswagen could now claim the world production record for the most-produced, single make of car in history. By 1973, total production was over 16 million.

To commemorate its passing the Ford Model T’s record sales mark and its victories in the Baja 1000 Mexican races from 1967 to 1971, Volkswagen produced its first limited-edition Beetle. It was marketed as the “Baja Champion SE” in the United States and the “Marathon” Superbeetle in the rest of the world. It featured unique “Marathon Blau” metallic blue paint, steel-pressed 10-spoke 15-inch (38 cm) magnesium-alloy wheels, a commemorative metal plate mounted on the glovebox and a certificate of authenticity presented to the original purchaser. Dealer-installed options for this limited-edition Superbeetle included the following: white stripes running the length of the rocker-panel, a special shifter knob, bumper overriders, tapered exhaust tips, fake walnut inserts in the dashboard (behind the steering wheel and the glovebox cover) as well as Bosch fog lights mounted on the front bumper.

1961–1973: Beetle to Golf

The 1961 Type 1 Beetle had a 36 hp 1200cc four cylinder air-cooled flat-four opposed OHV engine made of aluminum alloy block and heads. By 1966, the Type 1 came with a 1300 engine. By 1967 the Type 1 had a 1500 engine, and 1600 in 1970. The air-cooled engine lost favor in the USA market with the advent of non-leaded gasoline and smog controls. These air-cooled engines were commonly tuned to be fuel rich in order to control engine over-heating, and this led to excessive carbon monoxide emissions. VW Production equipment was eventually moved to Mexico where vehicle emissions were not regulated. Beetles were popular on the USA West Coast where the limited-capacity cabin heating was less inconvenient. Beetles were popularized on the USA West Coast as beach buggies and dune buggies.

VW expanded its product line in 1961 with the introduction of four Type 3 models (Karmann Ghia, Notchback, Fastback, and Variant) based on the new Type 3 mechanical underpinnings. The name ‘Squareback’ was used in the U.S.A for the Variant.

In 1969 the larger Type 4 (411 and 412) models were introduced. These differed substantially from previous vehicles, with the notable introduction of monocoque/unibody construction, the option of a fully automatic transmission, electronic fuel injection, and a sturdier powerplant.

Volkswagen added a “Super Beetle” (the Type 131) to its lineup in 1971. The Type 131 differed from the standard Beetle in its use of a MacPherson strut front suspension instead of the usual torsion bars. The Super Beetle featured a new hooded, padded dash and curved windshield (from 1973 model year on up). Rack and pinion steering replaced recirculating ball steering gears in model year 1975 and up. The front of the car was stretched 2 inches (51 mm) to allow the spare tire to lie flat, and the combination of these two features increased the usable front luggage space.

In 1973, Volkswagen introduced the military-themed Type 181, or “Trekker” in Europe, “Thing” in America, recalling the wartime Type 82. The military version was produced for the NATO-era German Army during the Cold War years of 1970 to 1979. The U.S. Thing version only sold for two years, 1973 and 1974.

In 1964, Volkswagen acquired Auto Union, and in 1969, NSU Motorenwerke AG (NSU). The former company owned the historic Audi brand, which had disappeared after the Second World War. VW ultimately merged Auto Union and NSU to create the modern Audi company, and would go on to develop it as its luxury vehicle marque. The purchase of Auto Union and NSU was a pivotal point in Volkswagen’s history, as both companies yielded the technological expertise that proved necessary for VW to survive when demand for its air-cooled models went into decline.

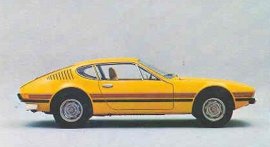

By late 1972, Volkswagen had decided to cancel the nearly finished typ 266, a project for a mid-engined car to replace the Beetle, and to focus on front-wheel-drive, water-cooled cars. Rudolf Leiding, recently made head of Volkswagen, cited noise, heat, and servicing problems with the mid-engine layout, as well as the difficulty of making it a station wagon.

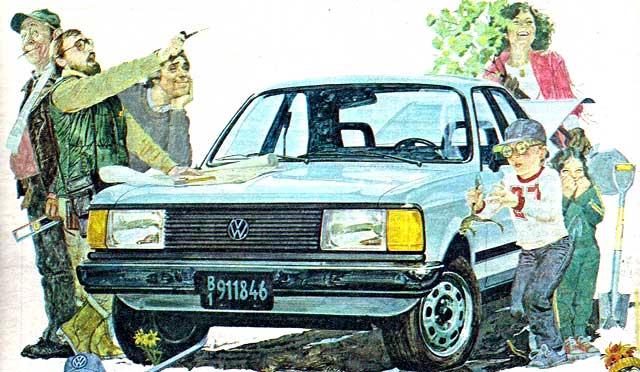

Volkswagen was in serious trouble by 1973. The Type 3 and Type 4 models had sold in much smaller numbers than the Beetle and the NSU-based K70 also failed to woo buyers. Beetle sales had started to decline rapidly in European and North American markets. The company knew that Beetle production had to end, but faced a conundrum of how to replace it. VW’s ownership of Audi/Auto Union proved beneficial. Its expertise in front-wheel drive, and water-cooled engines would help Volkswagen produce a credible Beetle successor. Audi influences paved the way for this new generation of Volkswagens: the Passat, Scirocco, Golf, and Polo.

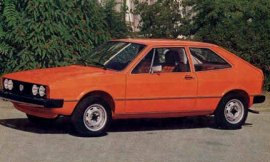

First in the series was the Volkswagen Passat (Dasher in the US), introduced in 1973, a fastback version of the Audi 80, using many identical body and mechanical parts. Estate/wagon versions were available in many markets. In Europe, the estate/wagon version dominated in market share for many years.

In spring 1974, the Scirocco followed. The coupe was designed by Giorgetto Giugiaro. Based on the platform of the not yet released Golf, it was built at Karmann due to capacity constraints at Volkswagen.

The pivotal model emerged as the Volkswagen Golf in 1974, marketed in the United States and Canada as the Rabbit for the 1st generation (1975–1985) and 5th generation (2006–2009). Its angular styling was designed by the Italian Giorgetto Giugiaro). Its design followed trends for small family cars set by the 1959 Mini – the Golf had a transversely mounted, water-cooled engine in the front, driving the front wheels, and had a hatchback, a format that has dominated the market segment ever since. Beetle production at Wolfsburg ended upon the Golf’s introduction. It continued in smaller numbers at other German factories (Hanover and Emden) until 1978, but mainstream production shifted to Brazil and Mexico.

In 1975, the Volkswagen Polo followed. It was a re-badged Audi 50, which was soon discontinued in 1978. The Polo became the base of

the Volkswagen Derby, which was introduced 1977. The Derby was for all intents and purposes a three-box design of the Polo. After a second model generation, the Derby was discontinued in 1985, although the bodystyle lived on in the form of the polo classic/polo saloon until 1991.

Passat, Scirocco, Golf, and Polo shared many character defining features, as well as parts and engines. They built the basis for Volkswagen’s turn-around.

1974–1990: Product line expansion

While Volkswagen’s range of cars soon became similar to that of other large European automakers, the Golf has been the mainstay of the Volkswagen lineup since its introduction, and the mechanical basis for several other cars of the company. There have been seven generations of the Volkswagen Golf, the first of which was produced from the summer of 1974 until the autumn of 1983 (sold as the Rabbit in the United States and Canada and as the Caribe in Latin America). Its chassis also spawned the Volkswagen Scirocco sport coupe, Volkswagen Jetta saloon/sedan, Volkswagen Golf Cabriolet convertible, and Volkswagen Caddy pick-up. North American production of the Rabbit commenced at the Volkswagen Westmoreland Assembly Plant near New Stanton, Pennsylvania in 1978. It would be produced in the United States as the Rabbit until the spring of 1984.The second-generation Golf hatchback/Jetta sedan ran from October 1983 until the autumn of 1991, and a North American version produced at Westmoreland Assembly went on sale at the start of the 1985 model year. The production numbers of the first-generation Golf has continued to grow annually in South Africa as

the Citi Golf, with only minor modifications to the interior, engine and chassis, using tooling relocated from the New Stanton, Pennsylvania plant when that site began to build the Second Generation car.

In the 1980s, Volkswagen’s sales in the United States and Canada fell dramatically, despite the success of models like the Golf elsewhere. The Japanese and the Americans were able to compete with similar products at lower prices. Sales in the United States were 293,595 in 1980, but by 1984 they were down to 177,709. The introduction of the second-generation Golf, GTI and Jetta models helped Volkswagen briefly in North America. Motor Trend named the GTI its Car of the Year for 1985, and Volkswagen rose in the J.D. Power buyer satisfaction ratings to eighth place in 1985, up from 22nd a year earlier. VW’s American sales broke 200,000 in 1985 and 1986 before resuming the downward trend from earlier in the decade. Chairman Carl Hahn decided to expand the company elsewhere (mostly in developing countries), and the New Stanton, Pennsylvania factory closed on 14 July 1988. Meanwhile, four years after signing a cooperation agreement with the Spanish car maker SEAT in 1982, Hahn expanded the company by purchasing a majority share of SEAT up to 75% by the end of 1986, which VW bought outright in 1990. On 4 July 1985, Volkswagenwerk AG was renamed to Volkswagen AG.

Volkswagen entered the supermini market in 1975 with the Volkswagen Polo, a stylish and spacious three-door hatchback designed by Bertone. It was a strong seller in West Germany and most of the rest of Western Europe, being one of the first foreign small cars to prove popular in Britain. It had started out in 1974 as the Audi 50, which was only available in certain markets and was less popular. The Polo entered a market sector already being dominated by the Fiat 127 and Renault 5, and which before long would also include the Austin Metro and Ford Fiesta.

In 1981, the second-generation Polo launched and sold as a hatchback and “coupe” (with the hatchback resembling a small estate car and the coupe being similar to a conventional hatchback), was an even greater success for Volkswagen. Its practicality, despite the lack of a five-door version, helped ensure even stronger sales than its predecessor, and it continued to sell well after a makeover in 1990, finally being replaced by an all-new version in 1994. Also arriving in 1981 were the second generation of the larger Passat and a second generation of the Volkswagen Scirocco coupe. The original Scirocco had been launched in 1974 to compete with affordable four-seater coupes like the Ford Capri.

In 1983 the MK2 Golf was launched. At the beginning of 1988, the third generation Passat was the next major car launch and Volkswagen did not produce a hatchback version of this Passat, despite the rising popularity of the hatchback bodystyle throughout Europe. Just after launching the B3 Passat, Volkswagen launched the Corrado, replacement for the Scirocco, although the Scirocco remained in production until 1992.

1991–1999

In 1991, Volkswagen launched the third-generation Golf, which was European Car of the Year for 1992. The Golf Mk3 and Jetta arrived in North America in 1993. The sedan version of the Golf was badged Vento in Europe, but remained Jetta in the U.S. The Scirocco and the later Corrado were both Golf-based coupés.

In 1994, Volkswagen unveiled the J Mays-designed Concept One, a “retro”-themed concept car with a resemblance to the original Beetle, based on the platform of the Polo. Due to a positive response to the concept, a production version was developed as the New Beetle, based on the Golf’s larger platform.

In 1995 the Sharan was launched in Europe, the result of a joint venture with Ford, which also resulted in the Ford Galaxy and SEAT Alhambra.

The company’s evolution of its model range was continued with the Golf Mk4, introduced at the end of 1997 (and in North America in 1999), its chassis spawned a host of other cars within the Volkswagen Group; the Volkswagen Bora (the sedan called Jetta in the U.S.), SEAT Toledo, SEAT León, Audi A3, Audi TT, and Škoda Octavia. Other main models during the decade include the Polo, a smaller car than the Golf, and the larger Passat for the segment above the Golf.

In 1998 the company launched the new Lupo city car. In 1999 they announced the first “3-litre” car, a lightweight version of the Lupo that could travel 100 km with only 3-litres of diesel—making it the world’s most fuel efficient car at the time.

2000–present: Further expansion

The fifth generation Volkswagen Jetta

The fifth generation Volkswagen JettaVolkswagen began introducing an array of new models after Bernd Pischetsrieder became Volkswagen Group CEO (responsible for all Group brands) in 2002. The sixth-generation VW Golf was launched in 2008, came runner-up to the Opel/Vauxhall Insignia in the 2009 European Car of the Year, and has spawned several cousins: VW Jetta, VW Scirocco, SEAT León, SEAT Toledo, Škoda Octavia and Audi A3 hatchback ranges, as well as a new mini-MPV, the SEAT Altea. The GTI, a “hot hatch” performance version of the Golf, boasts a 2.0 L Turbocharged Fuel Stratified Injection (FSI) direct injection engine. VW began marketing the Golf under the Rabbit name once again in the U.S. and Canada in 2006.

The sixth-generation Passat and the fifth-generation Jetta both debuted in 2005, and VW announced plans to expand its lineup further by bringing back the Scirocco by 2008. Other models in Wolfgang Bernhard‘s (Volkswagen brand CEO) “product offensive” include the Tiguan mid-sized SUV in 2008 and a Passat Coupé. In November 2006 Bernd Pischetsrieder announced his resignation as Volkswagen Group CEO, and was replaced by Audi worldwide CEO Martin Winterkorn at the beginning of 2007.

The third generation Volkswagen Scirocco

The third generation Volkswagen SciroccoVolkswagen in 2005 maintained North American sales of 224,195. Momentum continued for fiscal 2006, as VW’s North American sales for the year were 235,140 vehicles, a 4.9 percent increase over 2005, despite a slump in domestic North American manufacturer’s sales. In conjunction with the introduction of new models, production location of Volkswagen vehicles also underwent great change. The 2007 Eos, a hardtop convertible, is produced in a new facility in Portugal. All Golfs/Rabbits and GTIs as of 2006 are manufactured in Wolfsburg, Germany, rather than VW’s Mexican factory in Puebla, where Golfs and GTIs for the North American market were produced from 1989 to 1998, and the Brazilian factory in Curitiba, where Golfs and GTIs were produced from 1999 to 2006 (the Jetta has primarily been made in Mexico since 1989). VW is also in the process of reconfiguring an automotive assembly plant in Belgium. The new models and investments in manufacturing improvements were noticed immediately by automotive critics. Favorable reviews for VW’s newest cars include the GTI being named by Consumer Reports as the top sporty car under $25,000, one of Car and Driver magazine’s “10 Best” for 2007, Automobile Magazine’s 2007 Car of the Year, as well as a 2008 Motor Trend comparison ranking the mid-size Passat first in its class.

The seventh generation Volkswagen Golf

The seventh generation Volkswagen GolfVolkswagen partnered with Daimler AG and other companies to market the BlueTec clean dieseltechnology on cars and trucks from Mercedes-Benz, Volkswagen, and other companies and brands. According to the United States Environmental Protection Agency, four of the ten most fuel-efficient vehicles available for sale in the U.S. are powered by Volkswagen diesel engines. Volkswagen has offered a number of its vehicles with a TDI (Turbocharged Direct Injection) engine, which lends class-leading fuel economy to several models. They were a three-way tie for 8th (TDI Beetle, TDI Golf, TDI Jetta) and ninth, the TDI Jetta Wagon. In addition, all Volkswagen TDI diesel engines produced from 1996 to 2006 can be driven on 100% biodiesel fuel. For the 2007 model year, however, strict U.S. government emissions regulations have forced VW to drop most diesels from their U.S. engine lineup, but a new lineup of diesel engines compatible to U.S. standards returned to the American market starting with Model Year 2009. These post-2009 Clean Diesel engines are limited to running on 5% (B5) biodiesel only to maintain Volkswagen’s warranty. Volkswagen long resisted adding a SUV to its lineup, but relented with the introduction of

the Touareg, made in partnership with Porsche, while they worked on the Porsche Cayenne and later the Audi Q7. Though acclaimed as a fine handling vehicle, the Touareg has been a modest seller at best, and it has been criticised by auto reviewers for its absence of a third-row seat, the relatively poor fuel economy, and the high vehicle mass. VW set plans to add a compact SUV with styling influences from the “Concept A” concept vehicle introduced at the 2006 Geneva Auto Show, and on 20 July 2006, VW announced that the new vehicle, called

the Tiguan.

Since the discontinuance of the T4 in 2003 and decision not to bring the T5 to the US market, Volkswagen, ironically, lacked a van in its North American lineup. To change this, Volkswagen launched the Volkswagen Routan, a badge-engineered Dodge Grand Caravan made for the American and Canadian markets, in 2008.

In September 2006, Volkswagen began offering the City Golf and City Jetta only for the Canadian market. Both models were originally the Mk4 Golf and Jetta but were later replaced with the Brazilian versions of the Golf Mk4 and Bora. Volkswagen’s introduction of such models is seen as a test of the market for a subcompact and, if successful, may be the beginnings of a thriving subcompact market for Volkswagen.

The Volkswagen Passat (3C)

The Volkswagen Passat (3C)In May 2011, Volkswagen completed Chattanooga Assembly in the US state of Tennessee. The facility has produced Volkswagen cars and SUVs specifically designed for North American markets, beginning with the Passat B7 in 2011. The company recently announced plans to expand further by investing $900 million to add floor space to the factory.

The VW XL1 began a limited production run in 2013. The XL1 is a lightweight and fuel efficient two-person vehicle (only 795 kg).

The Volkswagen Atlas (a large crossover SUV) begins production in late 2016, and aims to help end several years of losses for Volkswagen in the US, the world’s second-largest auto market.

On 14 September 2016, Volkswagen announced its partnership with three Israeli cybersecurity experts to create a new company, Cymotive, dedicated to automotive security.

VW calls their shift towards electric vehicles “Transform 2025+”. As part of the strategy, VW aims to launch more than 30 electric vehicles until 2025, and is anticipating yearly sales of 2 to 3 million electric VW cars by 2025, which would make up 20 to 25 percent of their total yearly sales volume. In September 2017, CEO Matthias Mueller announced plans to have electric version of all of VW’s 300 automotive models by 2030. The company vows to spend 20 billion euros by 2030 to roll out the cars and designated another 50 billion euros to buy the batteries needed to power the vehicles.

In April 2018, Volkswagen has finally whipped the covers of its first all-electric race car, the I.D. R Pikes Peak, which has been built to conquer the road race of the same name. The I.D. R Pikes Peak was unveiled in Alès, France, and should be ready to roll in two short months. It will be powered by twin engines, though this time around they’ll be strictly electric. With a lithium-ion battery system on board, the car generates 680 hp and 479 lb-ft of torque.

Operations

Volkswagen is the founding and namesake member of the Volkswagen Group, a large international corporation in charge of multiple car and truck brands, including Audi, SEAT, Porsche, Lamborghini, Bentley, Bugatti, Scania, MAN, and Škoda. Volkswagen Group’s global headquarters are located in Volkswagen’s historic home of Wolfsburg, Germany.

Volkswagen Group, as a unit, is Europe’s largest automaker. For a long time, Volkswagen has had a market share over 20 percent.

In 2010, Volkswagen posted record sales of 6.29 million vehicles, with its global market share at 11.4%. In 2008, Volkswagen became the third largest automaker in the world, and, as of 2012, Volkswagen is the second largest manufacturer worldwide. Volkswagen has aimed to double its US market share from 2% to 4% in 2014, and is aiming to become, sustainably, the world’s largest car maker by 2018. Volkswagen Group’s core markets include Germany and China.

Worldwide presence

Volkswagen has factories in many parts of the world, manufacturing or assembling vehicles for local markets. In addition to plants in Germany, Volkswagen has manufacturing or assembly facilities in Mexico, the US, Slovakia, China, India, Indonesia, Russia, Malaysia, Brazil, Argentina, Portugal, Spain, Poland, the Czech Republic, Bosnia and Herzegovina, Kenya and South Africa. In 2011, Volkswagen was named in the top 25 largest companies in the world by the Forbes Global 2000.

Volkswagen is setting up a new factory in West Java, Indonesia, which started construction in mid-2013. The investment into the new plant, which will produce large transporters and multivans, is valued at $140 million.

As of May 2014, Volkswagen is planning to start assembling certain engines in India to increase localisation from 70% to 90%.

In January 2016, Volkswagen announced launching a new factory in Algeria during a summit between Angela Merkel and Algerian prime minister Abdelmalek Sellal.

Work–life balance

Volkswagen agreed in December 2011 to implement a rule passed by the company’s works council aimed at improving work–life balanceby restricting company email functionality on the firm’s BlackBerry smartphones from 6:30 pm to 7:30 am. The change was a response to employees’ complaints about high stress levels at work and the expectation that employees would immediately answer after-hours email from home. About 1,150 of Volkswagen’s more than 190,000 employees are affected by the email restriction.

Relationship with Porsche and the Volkswagen Law

Volkswagen has always had a close relationship with Porsche, the Zuffenhausen-based sports car manufacturer founded in 1931 by Ferdinand Porsche, the original Volkswagen designer and Volkswagen company co-founder, hired by Adolf Hitler for the project. The first Porsche car, the Porsche 64 of 1938, used many components from the Volkswagen Beetle. The 1948 Porsche 356 continued using many Volkswagen components, including a tuned engine, gearbox and suspension.

The two companies continued their collaboration in 1969 to make the VW-Porsche 914 and Porsche 914-6. (The 914-6 had a 6-cylinder Porsche engine, and the standard 914 had a Volkswagen engine.) Volkswagen and Porsche would collaborate again in 1976 on the Porsche 912-E (USA only) and the Porsche 924, which used many Audi components and was built at Audi’s Neckarsulm facilities. The 924 was originally designated for AUDI. Most Porsche 944 models were built there, although they used far fewer VW components.

The Porsche Cayenne, introduced in 2002, shares its entire chassis with the Volkswagen Touareg and Audi Q7, and is built at the same Volkswagen factory in Bratislava that the other SUV’s are built.

In September 2005, Porsche announced it would increase its 5% stake in Volkswagen to 20% at a cost of €3 billion, with the intention that the combined stakes of Porsche and the government of Lower Saxony would ensure that any hostile takeover by foreign investors would be impossible. Speculated suitors included DaimlerChrysler, BMW, and Renault. In July 2006, Porsche increased their ownership again to 25.1%.

On 4 March 2005, the European Commission brought an action against the Federal Republic of Germany before the European Court of Justice, claiming that the Volkswagen Law, which prevents any shareholder in Volkswagen from executing more than 20% of the total voting rights in the firm, was illegally restricting the flow of capital in Europe. On 13 February 2007, Advocate General Dámaso Ruiz-Jarabo Colomer submitted an opinion to the court in support of the action. This again opened the possibility of a hostile takeover of VW and so on 26 March of the same year Porsche took its holding of Volkswagen shares to 30.9%. Porsche formally announced in a press statement that it did not intend to take over Volkswagen, but intended the move to avoid a competitor’s taking a large stake and to stop hedge funds from dismantling VW. As expected, on 22 October 2007, the European Court of Justice ruled in agreement with Ruiz-Jarabo and the law was struck down. In October 2007, the European Court of Justice ruled that the VW law was illegal because it was protectionist. At that time, Porsche held 31% of VW shares — although a smaller proportion of voting rights, due to the Volkswagen Law — and there had been speculation that Porsche would be interested in taking over VW if the law did not stand in its way. The court also prevented the government from appointing Volkswagen board members. The German government then rewrote the Volkswagen law, only to be sued again. In October 2013, the EU Court of Justice in Luxembourg ruled that the rewritten Volkswagen law “complied in full” with EU rules.

On 26 October 2008, Porsche revealed its plan to assume control of VW. As of that day, it held 42.6% of Volkswagen’s ordinary shares and stock options on another 31.5%. Combined with the state of Lower Saxony’s 20.1% stake, this left only 5.8% of shares on the market—mostly with index funds that could not legally sell. Hedge funds desperate to cover their short positions forced Volkswagen stock above one thousand euros per share, briefly making it the world’s largest company by market capitalisation on 28 October 2008. By January 2009, Porsche had a 50.76% holding in Volkswagen AG, although the “Volkswagen Law” prevented it from taking control of the company.

On 6 May 2009, the two companies decided to join together, in a merger.

On 13 August, Volkswagen Aktiengesellschaft’s Supervisory Board signed the agreement to create an integrated automotive group with Porsche led by Volkswagen. The initial decision was for Volkswagen to take a 42.0% stake in Porsche AG by the end of 2009, and it would also see the family shareholders selling the automobile trading business of Porsche Holding Salzburg to Volkswagen. In October 2009 however, Volkswagen announced that its percentage in Porsche would be 49.9% for a cost of €3.9 billion (the 42.0% deal would have cost €3.3 billion). On 1 March 2011, Volkswagen has finalized the purchase of Porsche Holding Salzburg (PHS), Austria’s leading specialty automobile distributor, for €3.3 billion ($4.55 billion).

AutoMuseum

Since 1985, Volkswagen has run the Volkswagen AutoMuseum in Wolfsburg, a museum dedicated specifically to the history of Volkswagen. In addition to visiting exhibits in person, owners of vintage Volkswagens anywhere in the world may order what the museum refers to as a “Birth Certificate” for a set fee of €50—this formal “Zertifikat” indicates basic information known at the time of manufacture (colors, options, port of destination, etc.).

Global sales figures, 2006-2016

| Year | Global sales (in millions) |

|---|---|

| 2006 | 5.7 |

| 2007 | 6.2 |

| 2008 | 6.3 |

| 2009 | 6.3 |

| 2010 | 7.3 |

| 2011 | 8.4 |

| 2012 | 9.3 |

| 2013 | 9.7 |

| 2014 | 10.2 |

| 2015 | 10.0 |

| 2016 | 10.3 |

Current models

2012 Volkswagen up! (AA MY13) 5-door hatchback (2015-11-11) 01

Up! City Car Hatchback

2014-present Volkswagen Gol Mk6 Sedan

2014-present Volkswagen Gol Mk6 Sedan

Gol City Car Hatchback – Sedan – Coupé Utility

Ameo City Car Sedan

2015 Volkswagen Fox in Punta del Este 01

2015 Volkswagen Fox in Punta del Este 01

Fox (South America) Supermini Hatchback – Estate

2005-2010 Volkswagen Polo IV (9N3) GTI 3-door hatchback

2005-2010 Volkswagen Polo IV (9N3) GTI 3-door hatchback

Polo Supermini Hatchback – Coupé – Estate

Vento Subcompact car Sedan

2012 Volkswagen Beetle

Beetle Small family car Hatchback – Convertible

2017 VW Golf Variant 1.4 TSI BlueMotion Technology Highline (VII, Facelift)

Golf Small family car Hatchback – Estate – Convertible

GTI models

2015 Volkswagen Golf GTi (16460156619)

2015 Volkswagen Golf GTi (16460156619)

Golf GTI Small family car Hatchback

Electric models

GTE models

GTE are plug-in hybrid electric vehicles The GTE’s engine, electric motor, and transmission are fully shared with the Audi A3 Sportback e-tron:

2015 Black VW Golf GTE charging

2015 Black VW Golf GTE charging

Golf GTE Small family car Hatchback 1.4l and an electric motor can travel for a full 50km on electricity only

2014 Volkswagen Passat GTE Variant – Mondial de l’Automobile de Paris

Passat GTE Large family car Estate

e-models

VW e-models are all-electric vehicles.

2013 VW e-Golf LA Auto Show

R models

R models are exotic and sport vehicles.

Golf R Small sports car Hatchback

2015 Volkswagen Scirocco R (15977639104)

Scirocco R Small sports car Coupé

Historic models

Kübelwagen 1940–1945

Kübelwagen 1940–1945

Schwimmwagen 1942-1944

Schwimmwagen 1942-1944

Sedan, ”Beetle, Bug” 1938 – 2003

181 1969–1983

181 1969–1983 411 1968–1972

411 1968–1972 K70 1970–1974

K70 1970–1974 412 1972–1974

412 1972–1974 Scirocco 1974–1981

Scirocco 1974–1981 Derby 1977–1981

Derby 1977–1981Electric and alternative fuel vehicles

Neat ethanol vehicles

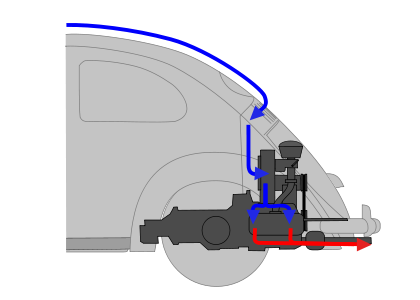

Volkswagen do Brasil produced and sold neat ethanol-powered, (E100 only), vehicles in Brazil, and production was discontinued only after they were supplanted by more modern Flex Fuel technology. As a response to the 1973 oil crisis, the Brazilian government began promoting bioethanol as a fuel, and the National Alcohol Program –Pró-Álcool– (Portuguese: Programa Nacional do Álcool) was launched in 1975. Compelled by the 1979 energy crisis, and after development and testing with government fleets by the CTA at São José dos Campos, and further testing of several prototypes developed by the four local carmakers, including Volkswagen do Brasil, neat ethanol vehicles were launched in the Brazilian market. Gasoline engines were modified to support hydrous ethanol characteristics and changes included compression ratio, amount of fuel injected, replacement of materials that would get corroded by the contact with ethanol, use of colder spark plugs suitable for dissipating heat due to higher flame temperatures, and an auxiliary cold-start system that injects gasoline from a small tank in the engine compartment to help starting when cold. Within six years, around 75% of all Brazilian passenger cars were manufactured with ethanol engines.

Production and sales of neat ethanol vehicles tumbled beginning in 1987 owing to several factors, including a sharp decline in gasoline prices as a result of the 1980s oil glut, and high sugar prices in the world market, shifting sugarcane ethanol production from fuel to sugar. By mid-1989, a shortage of ethanol fuel supply in the local market left thousands of vehicles in line at gas stations or out of fuel in their garages, forcing consumers to abandon ethanol vehicles.

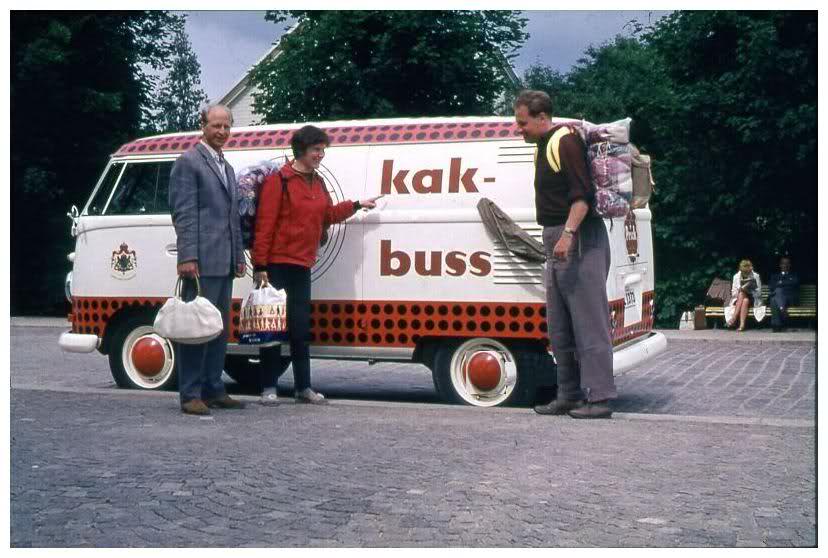

Flexible-fuel vehicles

Owing to the success and rapid consumer acceptance of the flex-fuel versions, by 2005 VW had sold 293,523 flex-fuel cars and light-duty trucks, and only 53,074 gasoline-only automobiles, jumping to 525,838 flex-fuel vehicles and only 13,572 gasoline-only cars and 248 gasoline-only light trucks in 2007, and reaching new car sales of 564,959 flex-fuel vehicles in 2008, representing 96% of all new cars and light-duty trucks sold in that year. VW do Brasil stopped manufacturing gasoline-only vehicles models for the local market in 2006, and all of the remaining gasoline-only Volkswagen models sold in Brazil are imported. The flex-fuel models currently produced for the local market are the Gol, Fox, CrossFox, Parati, Polo Hatch, Polo Sedan, Saveiro, Golf, and Kombi. By March 2009, Volkswagen do Brasil had attained the milestone mark of two million flex-fuel vehicles produced since 2003.

Hybrid vehicles

Volkswagen and Sanyo have teamed up to develop a battery system for hybrid cars. Volkswagen head Martin Winterkorn has confirmed the company plans to build compact hybrid electric vehicles. He has stated “There will definitely be compact hybrid models, such as Polo and Golf, and without any great delay”, with gasoline and diesel power. For example, Golf is the ideal model to go hybrid as the Golf 1.4 TSI was recently awarded the “Auto Environment Certificate” by the Oko-Trend Institute for Environmental Research, and was considered as one of the most environmentally friendly vehicles of 2007. Also underway at Volkswagen’s Braunschweig R&D facilities in Northern Germany is a hybrid version of the next-generation Touareg.

VW intends all future models to have the hybrid option. “Future VW models will fundamentally also be constructed with hybrid concepts,” VW head of development Ulrich Hackenberg told Automobilwoche in an interview. Hackenberg mentioned that the car based on the Up! concept seen at Frankfurt Motor Show, as well as all future models, could be offered with either full or partial hybrid options. The rear-engine up! will go into production in 2011. Nothing has been said about plug-in hybrid options.

Volkswagen announced at the 2010 Geneva Motor Show the launch of the 2012 Touareg Hybrid, scheduled for 2011. VW also announced plans to introduce diesel-electric hybrid versions of its most popular models in 2012, beginning with the new Jetta, followed by the Golf Hybrid in 2013 together with hybrid versions of the Passat. In 2012, the Volkswagen Jetta Hybrid set the world record to become the fastest hybrid car at 187 mph.

Plug-in electric vehicles

In November 2009, Volkswagen announced it has hired Karl-Thomas Neumann as its group chief officer for electric traction. VW’s Chief of research, Jürgen Leohold, said in 2010 the company has concluded hydrogen fuel-cell cars are not a viable option.

As of May 2016, the Volkswagen Group offers for retails customers nine plug-in electric cars, of which, three are all-electric cars: the Volkswagen e-Up!, e-Golf and Audi R8 e-tron, and six are plug-in hybrids: the Volkswagen Golf GTE, Passat GTE, Audi A3 Sportback e-tron, Q7 e-tron quattro, Porsche Panamera S E-Hybrid and Cayenne S E-Hybrid. Also two limited production plug-in hybrids were manufactured beginning in 2013, the Volkswagen XL1 (250 units) and the Porsche 918 Spyder (918 units). Total cumulative sales of all Volkswagen brand electrified cars since the start of their respective production is expected to reach about 103,000 by the end of 2016.

In order to comply with increasingly strict carbon dioxide emission limits in major markets, the VW Group expects to sell about one million all-electric and plug-in hybrid vehicles a year worldwide by 2025. The Group plans to expand its plug-in range with 20 new pure electric and plug-in hybrid cars, including two cars to compete with Tesla Motors, the Porsche Mission E all-electric car and the Audi e-tron quattro, which is expected to become the brand’s first mass production electric vehicle. According to Thomas Ulbrich, VW brand production chief, the carmaker has capacitty to build as many as 75,000 battery electric and plug-in hybrids a year if demand rises. Volkswagen announced in October 2015 that “it will develop a modular architecture for battery electric cars, called the MEB. The standardized system will be designed for all body structures and vehicle types and will allow the company to build emotionally appealing EVs with a range of up to 310 mi (500 km).” In June 2016, VW launched a program to develop 30 all-electric cars in 10 years, and sell 2-3 million electric cars per year by 2025. Due to lower manpower requirements for electric motors than for piston engines, VW expects a gradual workforce reduction as numbers of electric cars increase. VW considers battery factory ownership as too expensive.

Environmental record

In 1974 Volkswagen paid a $120,000 fine to settle a complaint filed by the Environmental Protection Agency over the use of so-called “defeat devices” that disabled certain pollution-control systems. The complaint said the use of the devices violated the U.S. Clean Air Act.

In 1996, Volkswagen first implemented its seven environmental goals in Technical Development with themes involving climate protection, resource conservation, and healthcare, through objectives such as reducing greenhouse emissions and fuel consumption, enabling alternative fuels, and avoiding hazardous materials. The goals have been revised in 2002 and 2007. Volkswagen was the first car manufacturer to apply ISO 14000, during its drafting stage and was re-certified under the standards in September 2005.

In 2011, Greenpeace began criticising Volkswagen’s opposition to legislation requiring tighter controls on CO2 emissions and energy efficiency, and launched an advertising campaign parodying VW’s series of Star Wars-based commercials.

In 2013, the Volkswagen XL1 became the most fuel-efficient production car in the world, with a claimed combined fuel consumption of 261 mpg (0.90 liter/100 km). Driving style has huge impact on this result – “normal” driving produces mileage in the 120 mpg range (1.96 liter/100 km).

As of 2014, VW is registered with a Corporate Average Fuel Economy (CAFE) of 34-38 mpg in USA.

Diesel emission violations

On 18 September 2015, the United States Environmental Protection Agency (EPA) said beginning in 2008 the automaker improperly installed engine control unit (ECU) software determined to be a “defeat device”, in violation of the Clean Air Act to circumvent environmental regulations of NOxemissions by diesel engine 2009-2015 model year Volkswagen and Audi cars. The software detects when the cars were being subject to emissions testing, and then fully enabled ECU emission controls to successfully pass. However, during normal driving conditions, emission control software was shut off in order to attain greater fuel economy and additional power, resulting in as much as 40 times more pollution than allowed by law. Consumer Reports tested a 2011 Jetta SportWagen TDI and found in emissions mode its 0-60 mph time increased by 0.6 seconds and its highway fuel economy dropped from 50 mpg to 46 mpg. Volkswagen admitted to using the defeat device, and has been ordered to recall approximately 482,000 cars with four-cylinder 2.0-liter TDI engines. United States federal penalties may include fines ranging up to US$18billion, and possibly criminal charges. On 28 June 2016, Volkswagen agreed to pay a settlement of $15.3 billion, the largest auto-related consumer class-action lawsuit in the United States history.

In May 2014, the EPA was first alerted to the issue by the International Council on Clean Transportation (ICCT), reporting results of research commissioned for them by West Virginia University‘s Center for Alternative Fuels, Engines and Emissions (CAFEE). After 15 months of denying the emissions control systems were deliberately gamed and instead claiming discrepancies due to “technical” reasons, on August 21 Volkswagen acknowledged to the EPA and California Air Resources Board (CARB) their emission controls systems were rigged. This was followed by a formal announcement of admission to regulators on September 3 which took place immediately after the EPA threatened to withhold approval for their 2016 cars. Volkswagen’s initial public response came on 20 September, when a spokesman said they would stop all US sales of the diesel models affected. Chairman Martin Winterkorn issued an apology and said Volkswagen would cooperate with investigators. Since emission standards in Canada are close to those in the US, Volkswagen Canada also halted sales of the affected diesel models. on 22 September 2015, Volkswagen spokesman admitted that the defeat device is installed in ~11 million vehicles with Type EA 189 diesel engines worldwide.

On the first business day after the news, Volkswagen’s stock price declined 20% and declined another 17% the following day, the same day a social media advertisement with Wired about “how diesel was re-engineered” was removed as well as a series of YouTube ads titled “Diesel Old Wives’ Tales”. On Wednesday, 23 September, Volkswagen chief executive officer Martin Winterkorn resigned. Volkswagen hired Kirkland & Ellis law firm for defense, the same firm that defended BP during the Deepwater Horizon oil spill.

On 2 November 2016, the EPA issued a second notice of violation (NOV) pertaining to certain diesel 3.0-liter V6 equipped Audis, Volkswagen Touaregs and Porsche Cayennes. The EPA found beginning with the 2009 model year all vehicles powered by the V6 were non-compliant. During testing the EPA, CARB and Transport Canada discovered software that activates pollution reduction systems when the automobiles are being driven under federal test conditions, otherwise during real world driving these devices are inactive. Volkswagen disputed the EPA’s findings stating their software was legally permitted, however shortly after Volkswagen issued a stop-sale for the EPA’s disputed vehicles and additional models the EPA did not question.

In March 2016, the US Federal Trade Commission sued Volkswagen for false advertising, because Volkswagen’s “clean diesel” vehicles were less environmentally friendly than advertised.

In November 2016, Volkswagen and its labour unions agreed to reduce the workforce by 30,000 people until 2021 as a result of the costs from the violations. However, 9,000 new jobs would come by producing more electric cars. Volkswagen also announced plans to become the world leader in electric cars, producing 1 million VW-EVs by 2025 and 3 million by the group, and a VW manager stated that its diesel cars would not become available in USA.

On 11 January 2017, Volkswagen agreed to plead guilty to the emissions-cheating scandal and to pay $4.3 billion in penalties. Six Volkswagen executives were charged. The following day, one of the indicted executives was ordered to be held without bail pending trial as it was feared that he would flee to Germany and extradition would be impossible. Senior VW management staff were warned not to travel to the US. On 23 January 2017, a US judge approved a $1.2 billion settlement in which 650 American dealers, “who, like consumers, were blindsided by the brazen fraud that VW perpetrated,” would receive an average of $1.85 million.

Awards

Volkswagen was named the fourth most influential car of the 20th century in the 1999 Car of the Century competition, for its Volkswagen Type 1 ’Beetle” model. It trailed only the Ford Model T, BMC Mini, and Citroën DS.

Volkswagen has produced three winners of the 50-year-old European Car of the Year award.

- 1992 – Volkswagen Golf

- 2010 – Volkswagen Polo

- 2013 – Volkswagen Golf

Volkswagen has produced five winners of the United States Motor Trend Car of the Year award — the original Car of the Year designation, which began in 1949.

- 1985 – Volkswagen GTI

- 1999 – Volkswagen New Beetle (Import COTY subgroup)

- 2004 – Volkswagen Touareg (Sport Utility Vehicle COTY subgroup)

- 2012 – Volkswagen Passat

- 2015 – Volkswagen Golf line-up

Volkswagen has already produced four winners of the recently developed World Car of the Year award.

- 2009 – Volkswagen Golf

- 2010 – Volkswagen Polo

- 2012 – Volkswagen up!

- 2013 – Volkswagen Golf

Motorsport

Formula racing

- In 1963, Formula Vee circuit racing, with cars built from easily available Beetle parts, started in the United States. It quickly spread to Europe and other parts of the world. It proved very popular as a low-cost route into formula racing.

- In 1971, Volkswagen of America started the more powerful Formula Super Vee, which became famous for hothousing new talent. In the 11 years it ran, until 1982, it produced a stable of world-famous Formula One drivers—names like Niki Lauda, Jochen Mass, Nelson Piquet, Jochen Rindt and Keke Rosberg. Volkswagen also notched up several victories, and the championship in Formula Three.

- In July 2011 Wolfgang Dürheimer, the director of Bugatti and Bentley, told German magazine Auto, Motor und Sport that “if [the VW group] is at the forefront of the auto industry, I can imagine us competing in Formula 1 in 2018. We have enough brands to pull it off.” They did not compete in F1 in 2018.

World Rally Championship

- In 1981, now based in Hanover, VW took a new direction into rallying, with the launch of the first-generation Golf, and Sweden’s Per Eklund, Frenchman Jean-Luc Thérier, and the Finn Pentti Airikkala. The final chapters in Volkswagen Racing UK’s rallying story were the ‘one-make’ Castrol Polo Challenge, and the Polo GTI ‘Super 1600’ in 2001.

- Volkswagen Motorsport won the World Rally Championship with Sébastien Ogier and co-driver Julien Ingrassia four years in a row from 2013 to 2016 in the Volkswagen Polo R WRC.

Dakar Rally

- In 1980, Volkswagen competed with the Audi-developed Iltis, placing 1st, 2nd, 4th and 9th overall.

- In 2003, the Hanover-based team entered with a 2WD buggy named Tarek, finishing 6th overall and 1st in the 2WD and Diesel class.

- In 2005, an updated Race-Touareg with slightly more power entered, with driver Bruno Saby finishing 3rd overall and 1st in the Diesel class.

- In 2006, the revised Race-Touareg entered, with driver Giniel de Villiers finishing 2nd overall and 1st in the Diesel class.

- Volkswagen won the 2009, 2010 and 2011 Dakar Rally, held in South America.

Volkswagen motorsport worldwide

- Europe: In 1998 the company founded the ADAC Volkswagen Lupo Cup, founded in 1998 (renamed Polo Cup in 2003, and Volkswagen Scirocco R-Cup from 2010 to 2014), and started the ADAC New Beetle Cup in 2000. In 2004, Volkswagen Commercial Vehicles entered the European Truck Racing series with the Volkswagen Titan truck – it became a back-to-back champion for the 2004 and 2005 series.

- United States: In 1976, Volkswagen entered the under-2000-cc Trans-Am Series, with the Scirocco, and they won their class outright. Beginning in 2008 Volkswagen introduced the Jetta TDI Cup. The Jetta TDI Cup is a SCCA sanctioned race series that features 25 drivers between the ages of 16 and 26 driving slightly modified 2009 Jetta TDIs. The series features 10 events at 8 different road courses across North America. There is $50,000 prize money at stake over the course of the series in addition to the $100,000 prize awarded to the champion of the series at the conclusion of the last race.

- Argentina: Many Volkswagen models have competed in TC 2000, including the 1980 to 1983 champion Volkswagen 1500 and the 1994 champion Volkswagen Gol.

- In 1999 and 2000, VW won the F2 Australian Rally Championship with the Golf GTI.

- Finland: In 2002, VW won the Finnish Rally Championship in a7/(F2), with a Golf Mk4 KitCar, with Mikko Hirvonen. In 1999 and 2000, VW won the Finnish Rally Championship in a7/(F2) with a Golf Mk3 KitCar. In 2000, 2001 and 2002, VW won the Finnish Racing Championship in Sport 2000 with a Golf Mk4.

- Austria: From 1967 until 1974, the Austrian sole distributor Porsche Salzburg entered the VW Beetle (1500, 1302S and 1303S) in Europe-wide rallies. Victories were achieved in 1972 and 1973 in the overall Austrian championship, on Elba, in the Acropolis rally (first in class). Top drivers were Tony Fall (GB), Achim Warmbold (D), Günter Janger (A), Harry Källström(S).

-

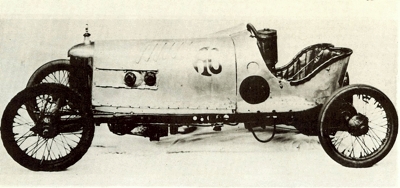

1939 Berlin to Rome. Porsche Type 64 racer based on Beetle platform

-

Twin-engine racing Beetle developed by Wilsonand Emerson Fittipaldi brothers

-

Edition 2007 Race Touareg 2 at Essen Motor Show 2006

-

Constellation in the 2006 Brazilian Fórmula Truck Championship

Literature

- Jonas Kiefer: VW Typenatlas, Serienfahrzeuge. 2. Auflage. Delius Klasing, Bielefeld 2002, ISBN 3-7688-1271-5.

- Rudi Heppe: VW Personenwagen. Podszun, Brilon 2001, ISBN 3-86133-209-4.

- Halwart Schrader: VW Personenwagen seit 1945, Band 1, Typenkompass. Motorbuch Verlag, Stuttgart 2001, ISBN 3-613-02105-6.

- Halwart Schrader: VW Personenwagen seit 1945, Band 2, Typenkompass. Motorbuch Verlag, Stuttgart 2001, ISBN 3-613-02186-2.

- Werner Oswald: Deutsche Autos, Band 2, 1920–1945. 2. Auflage. Motorbuch Verlag, Stuttgart 2005, ISBN 3-613-02170-6.

- Werner Oswald: Deutsche Autos, Band 3, 1945–1990, Ford, Opel und Volkswagen. 1. Auflage. Motorbuch Verlag, Stuttgart 2001, ISBN 3-613-02116-1.

The pictures I collected the last years, my own pictures and the ones from the worldwideweb:

End-Montage

Montage 412

Forschung und Entwicklungsabteilung

Forschung und Entwicklungsabteilung

Salzgitter Endmontage 412 und K70

Montage 412

Montage-Käfer

Montage 412

Forschung und Entwicklungsabteilung

Forschung und Entwicklung

PKW-Versuch/Abt. Sicherheit, Prüfgerät zur Belastung von Fahrzeugbauteilen mit Kräften, wie sie bei einem Crash auftreten.

1. März 1973

Endmontage Passat

Forschung und Entwicklung

Fahrzeug im Klimawindkanal, Messungen des aerodynamischen Verhaltens, Heizungs- und Belüftungseigenschaften bei unterschiedlichen Klimabedingungen

Montage 412

Staatssekretär Erwin Stahl besichtigt den Innovationsmarkt

That’s it what my collection has to show. There are some pictures double, I got them out so far as possible, but it was extremely hot today, so forgive. I hope you have a lot off pleasure.

That’s it what my collection has to show. There are some pictures double, I got them out so far as possible, but it was extremely hot today, so forgive. I hope you have a lot off pleasure.

Greetings Jeroen, your host!!

See also

- Baja bug

- Cal Look

- Fahrvergnügen

- List of German cars

- List of automobile manufacturers

- Punch buggy

- Standard Superior – a previous attempt to produce a “Volkswagen”

- Steyr 50

- Twin Drive

- VDub – tagline for the recent VWoA Golf GTI TV advertisemen*

- Volksflugzeug

- Volksrod

- Volkswagen advertising history

- VW 276 Schlepperfahrzeug, military use 1944

Notes

- ^ Tooze notes: “Even if the war had not intervened, developments up to 1939 made clear that the entire conception of the ‘people’s car’ was a disastrous flop.” Tooze (2006) p.156).

References

- ^ Bomey, Nathan (30 January 2017). “Volkswagen passes Toyota as world’s largest automaker despite scandal”. USA Today. Retrieved 20 June 2017.

- ^ Rodriguez, Ashley (23 December 2015). “‘Das Auto’ No More - Volkswagen’s new slogan is a lesson in humility”. Quartz. Retrieved 13 January 2016.

- ^ Cremer, Andreas (22 December 2015). “‘Das Auto’ no more: Volkswagen plans image offensive”. Reuters. Berlin. Retrieved 13 January 2016.

- ^ “VW pronunciation”. Forum.wordreference.com. Retrieved 2017-07-24.

- ^ Manfred Grieger; Ulrike Gutzmann; Dirk Schlinkert, eds. (2008). Volkswagen Chronicle (PDF). Historical Notes. 7. Volkswagen AG. ISBN978-3-935112-11-6. Archived from the original (PDF) on 16 December 2010. Retrieved 21 December 2009.

- ^ Miller, Elan (2009-09-13). “Was Hitler’s Beetle designed by a Jew?”. Jerusalem Post. Retrieved 2013-02-18.

- ^ abcd Nelson, Walter (1967). Small Wonder. Little, Brown & Company. p. 333.

- ^ Christoph Stehr (2 February 2016). “Das machen wir mal lieber neu”. Der Spiegel (in German). Retrieved 7 February 2016.

- ^ William Shirer, The Rise and Fall of the Third Reich (Touchstone Edition) (New York: Simon & Schuster, 1990)

- ^ “Last Edition Beetle: History”. Lasteditionbeetle.com. Archived from the original on 6 March 2008. Retrieved 22 September 2015.

- ^ König, Wolfgang. “Adolf Hitler vs. Henry Ford: The Volkswagen, the Role of America as a Model, and the Failure of a Nazi Consumer Society.” German Studies Review, vol. 27, no. 2, 2004, pp. 249–268. JSTOR, JSTOR, http://www.jstor.org/stable/1433081.

- ^ * Tooze, Adam (2006). The Wages of Destruction: The Making and Breaking of the Nazi Economy. London: Allen Lane. p. 154. ISBN978-0-7139-9566-4.

- ^ “Seventy-Five Years Ago: Porsche Receives the Order to Construct the Volkswagen”. porsche.com. Porsche AG. 16 June 2009. Archived from the original on 23 September 2016. Retrieved 22 January 2010.

- ^ abc Odin, L.C. World in Motion 1939 – The whole of the year’s automobile production. Belvedere Publishing, 2015. ASIN: B00ZLN91ZG.

- ^ “A Brief History Of Volkswagen”. hillsideimports.com. Retrieved 10 March 2015.

- ^ “Volkswagen Faces Suit Over Jewish Slave Labor”. The New York Times. 13 June 1998. Retrieved 18 May 2011.

- ^ “World: Americas German firms face slave labour case”. BBC News. 1 September 1998. Retrieved 18 May 2011.

- ^ Porter, Lindsay (October 1986). “Mr”. Thoroughbred & Classic Cars.

- ^ ab “Volkswagen Model 11 Beetle”. hillsideimports.com. 20 February 2014. Retrieved 4 April 2015.

- ^ “Harry S. Truman – Library & Museum – Draft, The President’s Economic Mission to Germany and Austria, Report 3, March, 1947; OF 950B: Economic Mission as to Food…; Truman Papers”. Trumanlibrary.org. Retrieved 27 September 2010.

- ^ Anders Ditlev Clausager (18 March 2000). Obituaries – Ivan HirstThe Guardian(UK).

- ^ Komplizen? - VW und die brasilianische Militärdiktatur. DasErste, ARD, 24.07.2017

- ^ VW worked hand in hand with Brazil’s military dictatorship24.07.2017 Deutsche Welle

- ^ Colin Shinkin About the 1972 Baja Champion SE – USAArchived 28 April 2015 at the Wayback Machine. (photos). SEBeetles.com.

- ^ Dean, Wayne (28 October 2006). “History of the Super Beetle”. superbeetles.com. Retrieved 6 May 2015.

- ^ Wilkins, Gordon (December 1972). “Volkswagenwerk plans new cars and engines”. CAR (South Africa). Vol. 16 no. 11. Cape Town, South Africa: Ramsay, Son & Parker (Pty) Ltd. p. 11.

- ^ William Beaver (Nov–Dec 1992). Volkswagen’s American assembly plant: Fahrvergnugen was not enough – international marketingfindarticles.com; Business Horizons.

- ^ Flammang, James, Volkswagen: Beetles, Buses and Beyond, Krause Publications, 1996

- ^ Kiley, David, Getting the Bugs Out: The Rise, Fall and Comeback of Volkswagen in America, John Wiley & Sons, 2001

- ^ Holusha, John (21 November 1987). “Volkswagen to Shut U.S. Plant”. New York Times. Retrieved 17 May 2008.

- ^ “A look at SEAT’s time line 2008-1950”. seat.com. SEAT S.A. Archived from the original on 18 July 2009.

- ^ “The VW Experimental Vehicles – the 1980s to present pt 2”. Wheelspin. London & Thames Valley VW Club. February 2003. Retrieved 12 July 2010.

- ^ “VW Sharan”. Car Magazine. 2 June 2011. Retrieved 4 January 2015.

- ^ “VW launches its economic miracle”. The Engineer. 5 January 2000. Retrieved 4 January 2015.

- ^ “Fuel Economy of New Diesel Cars”. Fueleconomy.gov. United States Environmental Protection Agency. 2012. Retrieved 5 December 2012.

- ^ Chris Bruce (7 April 2015). “Volkswagen plans expansion, tech center in Chattanooga”. Autoblog. Retrieved 22 September 2015.

- ^ Bloomberg News (16 July 2008). “VW picks Tenn. for its 1st US car plant since ’88”. Boston Globe.

- ^ “UPDATE: VW announces Chattanooga-made SUV, and 2,000 new jobs”. timesfreepress.com. Retrieved 22 September 2015.

- ^ By Charlie Osborne, ZDNet. “Volkswagen launches new cybersecurity firm to tackle car security.” September 15, 2016. Retrieved September 15, 2016.

- ^ “VW strives to be leader in e-cars, self-driving vehicles”. Deutsche Welle. Wolfsburg. May 5, 2017.

- ^ Rauwald, Christoph (September 11, 2017). “VW to Build Electric Versions of All 300 Models by 2030”. Bloomberg. Retrieved 11 October2017.

- ^ “Volkswagen reveals its first all-electric race car built to conquer Pikes Peak” New Atlas, April 23, 2018

- ^ “Group”. http://www.volkswagenag.com. Retrieved 2017-09-07.

- ^ ab Rauwald, Christoph (4 June 2012). “VW Bolsters Focus on China”. The Wall Street Journal. p. B3.

- ^ “New Car Registrations By Manufacturer(PDF)” (PDF). ACEA. 15 June 2010. Archived from the original (PDF) on 8 August 2011. Retrieved 2 July 2010.

- ^ “Volkswagen Posts Record 2009 Sales, Targets Toyota”. Bloomberg. 12 December 2010. Retrieved 12 December 2010.

- ^ “VW OVERTAKES FORD AS 3RD-LARGEST AUTOMAKER”. Left Lane News. 29 August 2008. Retrieved 12 December 2010.

- ^ “VW aims to double U.S. market share”. Freep. 12 December 2010. Retrieved 12 December 2010.

- ^ “Volkswagen will Autoimperium ausbauen (22397572) | börsennews.de”. Boersennews.de. 2009-09-15. Retrieved 2013-12-02.

- ^ “Google Translate”. Translate.google.com. Retrieved 2013-12-02.

- ^ “Volkswagen Group reports 6.7 percent growth in worldwide deliveries in July”. VW. 12 December 2010. Archived from the original on 25 July 2011. Retrieved 12 December 2010.

- ^ Watson, Todd (20 August 2013). “Volkswagen to open new plant in Indonesia”. Inside Investor. Retrieved 20 August 2013.

- ^ “The World’s Biggest Public Companies”. Forbes.com. Retrieved 6 June2011.

- ^ “Volkswagen”. Forbes. Retrieved 6 June 2011.

- ^ “German car makers push Indonesia”. Investvine.com. 2013-02-28. Retrieved 2013-04-03.

- ^ “Volkswagen plans engine assembly in India; to increase 90 per cent localisation”. The Times of India. Retrieved 22 September 2015.

- ^ “Automobile : bientôt une usine Volkswagen en Algérie ?”. Jeune Afrique (in French). 13 January 2016. Retrieved 23 January 2016.

- ^ Rzhevskiy, Ilya. “Volkswagen to Improve Work-Life Balance”. The Epoch Times. Retrieved 2 January 2012.

- ^ Rahn, Cornelius (23 December 2011), Volkswagen Employees Wary of Burnout Win Reprieve From BlackBerry Messages, Bloomberg L.P.

- ^ “Porsche wants 20% Volkswagen deal | 26 September 2005”. BBC News. 26 September 2005. Retrieved 27 September 2010.

- ^ Commission of the European Communities. “Action brought on 4 March 2005 by the Commission of the European Communities against the Federal Republic of Germany”. European Court of Justice. Retrieved 13 February 2012.

- ^ “Top EU court finds against VW law”. BBC News. 13 February 2007. Retrieved 27 September 2010.

- ^ “Porsche triggers VW takeover bid”. BBC News. 26 March 2007. Retrieved 27 September 2010.

- ^ Landler, Mark (23 October 2007). “Court Strikes Down ”Volkswagen Law””. New York Times. Germany. Retrieved 26 August 2011.

- ^ European Court of Justice. “Judgment of the Court (Grand Chamber) in Case C-112/05”. European Court of Justice. Retrieved 13 February 2012.

- ^ “THE VOLKSWAGEN LAW RESTRICTS THE FREE MOVEMENT OF CAPITAL” (PDF). COURT OF JUSTICE OF THE EUROPEAN COMMUNITIES. 23 October 2007. Retrieved 17 February 2013.

- ^ “‘Volkswagen law’ is ruled illegal”. BBC. 23 October 2007. Retrieved 17 February 2013.

- ^ “EU To Sue Germany Again Over ’Volkswagen Law'”. Wall Street Journal. 24 November 2011. Retrieved 17 February 2013.

- ^ Ramsey (27 November 2011). “Germany in court again over ”VW Law,” could face fines of nearly $375,000/day”. Autoblog. Retrieved 17 February 2013.

- ^ “Germany sued for second time over ’Volkswagen law'”. The Parliament. 25 November 2011. Retrieved 17 February 2013.

- ^ Bloomberg (22 October 2013). “Germany Wins EU Court Battle Over VW Law, Escapes Fines”. Retrieved 5 February 2014.

- ^ “Financial Times | Porsche plans to raise VW stake to 75%”. Financial Times. 26 October 2008. Retrieved 27 September 2010.

- ^ “VW vies for title of world’s biggest company”. Financial Times. 28 October 2008. Retrieved 27 September 2010.

- ^ “Porsche takes majority VW stake”. BBC News. 6 January 2009. Retrieved 16 June 2010.

- ^ “Volkswagen to take a 42.0 percent stake in Porsche AG”. Taume News. 14 August 2009. Archived from the original on 18 August 2009. Retrieved 22 January 2009.

- ^ “VW to buy half of Porsche by 2010”. BBC News. 20 October 2009. Retrieved 20 October 2009.

- ^ “VW purchase Porsche Holding Salzburg (PHS)”. IndustryWeek. 1 March 2011. Archived from the original on 24 March 2012. Retrieved 1 March 2011.

- ^ “:: Volkswagen AutoMuseum :: About us”. Automuseum.volkswagen.de. Archived from the original on 15 August 2011. Retrieved 26 August 2011.

- ^ “:: Volkswagen AutoMuseum :: Certificate Generator”. Automuseum.volkswagen.de. Archived from the original on 11 October 2011. Retrieved 26 August 2011.

- ^ Volkswagen’s worldwide vehicle sales from 2006 to 2016 (in millions)Statista – the statistics portal

- ^ “What the Cross Coupe GTE Concept Means for Volkswagen « Form Trends”. Formtrends.com. Retrieved 22 September 2015.

- ^ ab “2015 Volkswagen Golf GTE”. Caranddriver.com. Retrieved 22 September 2015.

- ^ “Electric mobility: the technology of electric cars - Volkswagen”. Emobility.volkswagen.com. Archived from the original on 22 September 2015. Retrieved 22 September 2015.

- ^ abc Milton Briquet Bastos (20 June 2007). “Brazil’s Ethanol Program – An Insider’s View”. Energy Tribune. Archived from the original on 10 July 2011. Retrieved 14 August 2008.

- ^ ab Revista Veja (13 June 1979). “O petróleo da cana” (in Portuguese). Editora Abril. Archived from the original on 6 October 2008. Retrieved 29 November 2008.

- ^ ab Marla Dickerson (17 June 2005). “Brazil’s ethanol effort helping lead to oil self-sufficiency”. The Seattle Times. Archived from the original on 27 December 2008. Retrieved 29 November 2008.

- ^ William Lemos (5 February 2007). “The Brazilian ethanol model”. ICIS news. Retrieved 14 August 2008.

- ^ Revista Veja (24 May 1989). “Um sonho corroído” (in Portuguese). Editora Abril. Archived from the original on 8 February 2009. Retrieved 29 November 2008.

- ^ Goettemoeller, Jeffrey; Adrian Goettemoeller (2007). “Sustainable Ethanol: Biofuels, Biorefineries, Cellulosic Biomass, Flex-Fuel Vehicles, and Sustainable Farming for Energy Independence”. Prairie Oak Publishing, Maryville, Missouri: 56–61. ISBN978-0-9786293-0-4.

- ^ ab “Volkswagen to stop making gas-only cars for Brazil”. Automotive News. 23 March 2006. Retrieved 18 October 2008.