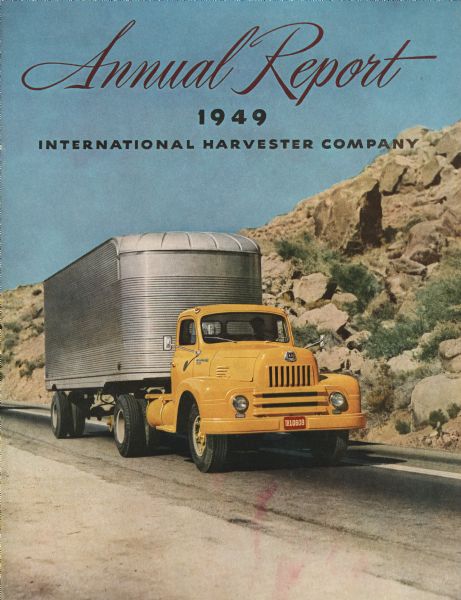

Navistar International Coorporation -International Harvester Company (II) 1902 – present Lisle Illinois United States of America

| Public | |

| Traded as | NYSE: NAV |

| Industry | Automotive |

| Predecessor | International Harvester Company |

| Founded | 1902 |

| Headquarters | Lisle, Illinois, United States |

|

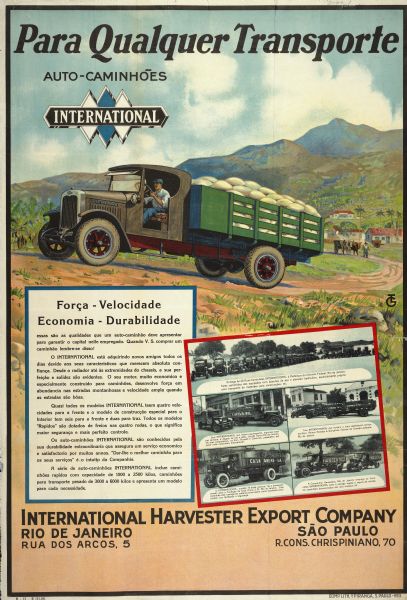

Area served

|

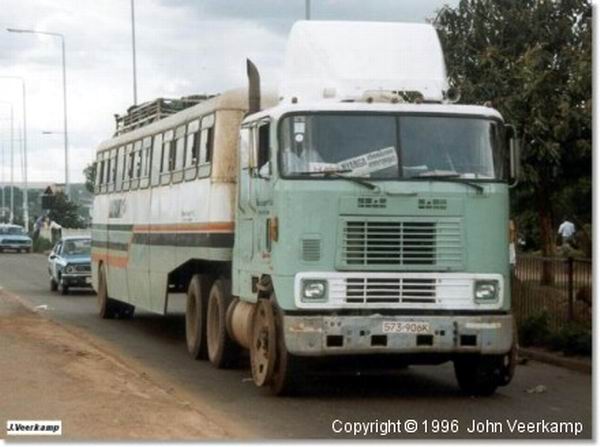

North America, South America, Russia, UK, Greece, Eastern Europe, India, Middle East, China, Singapore, South Korea |

|

Key people

|

Troy A. Clarke, President, Chief Executive Officer Walter G. Borst, Executive Vice President, Chief Financial Officer Steven K. Covey, Senior Vice President, General Counsel & Chief Ethics Officer |

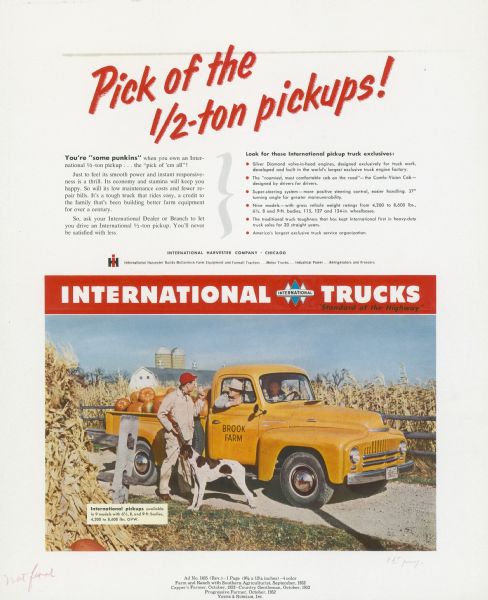

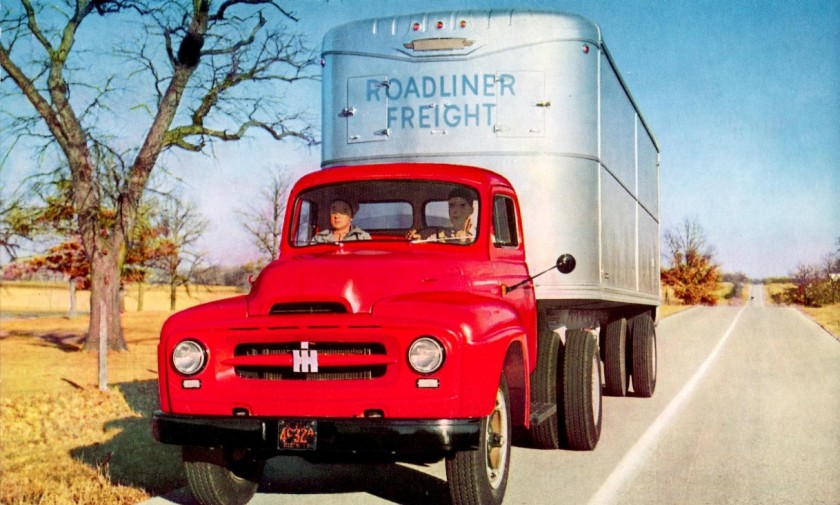

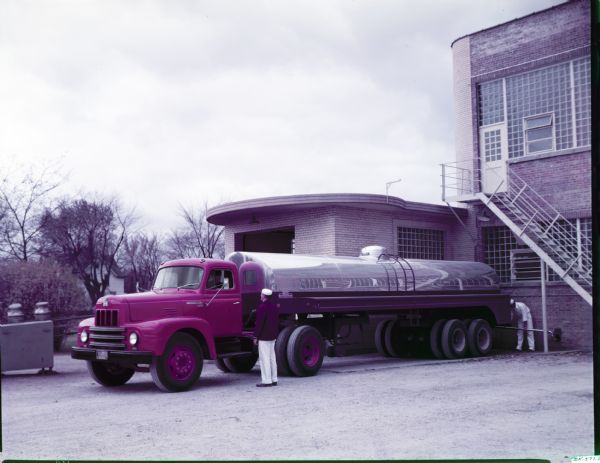

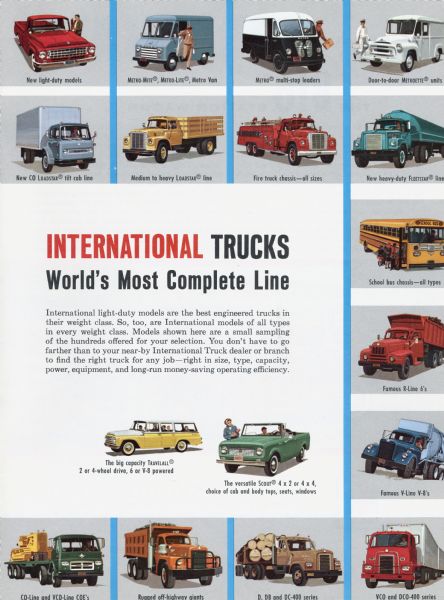

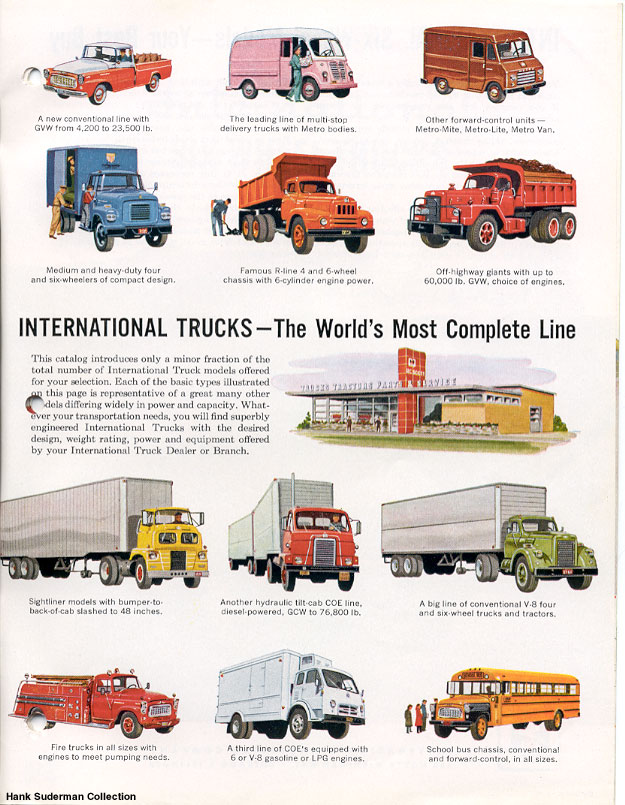

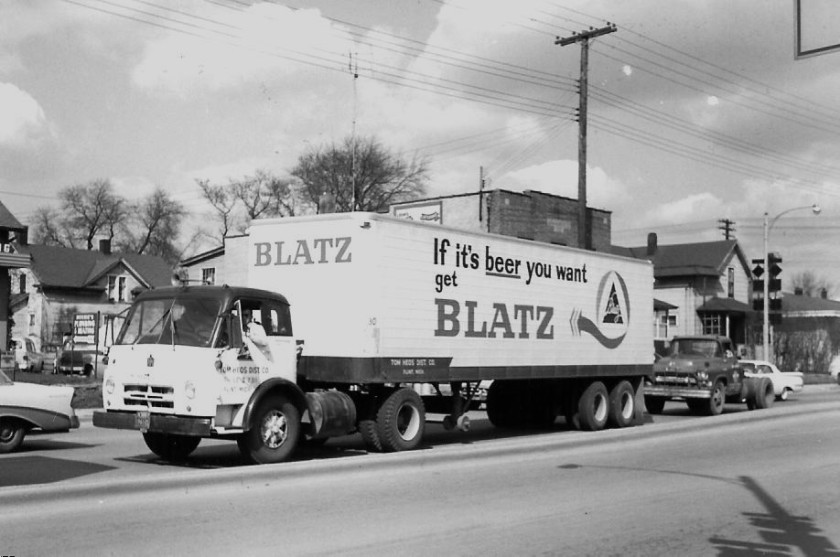

| Products | Trucks Buses and School buses, Diesel engines Chassis |

| Revenue | 10.775 billion USD(2013) |

|

Number of employees

|

16,500 |

| Website | www.navistar.com |

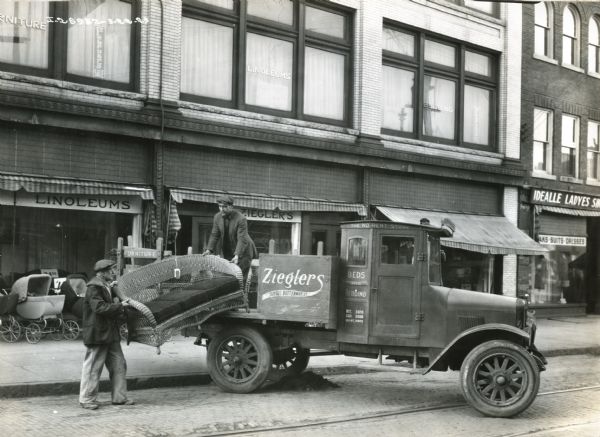

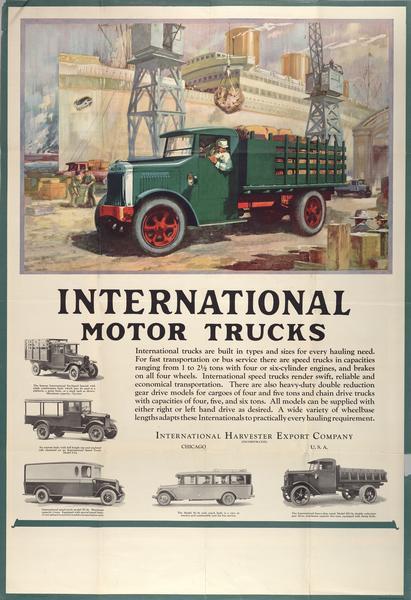

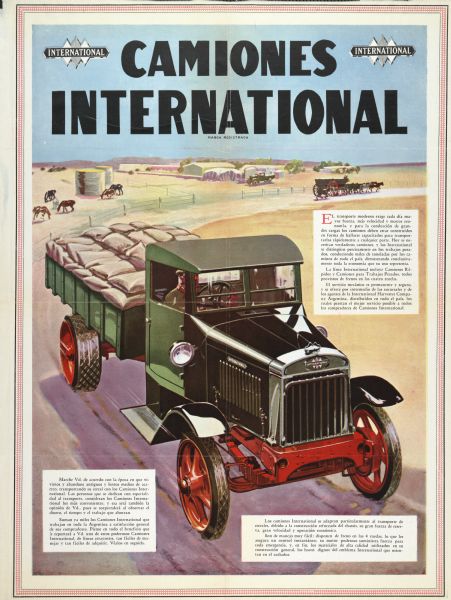

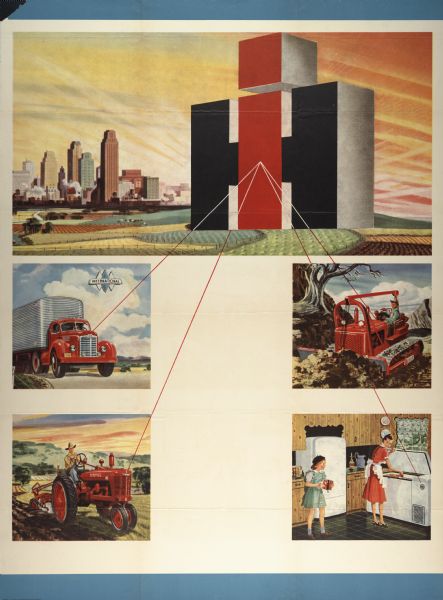

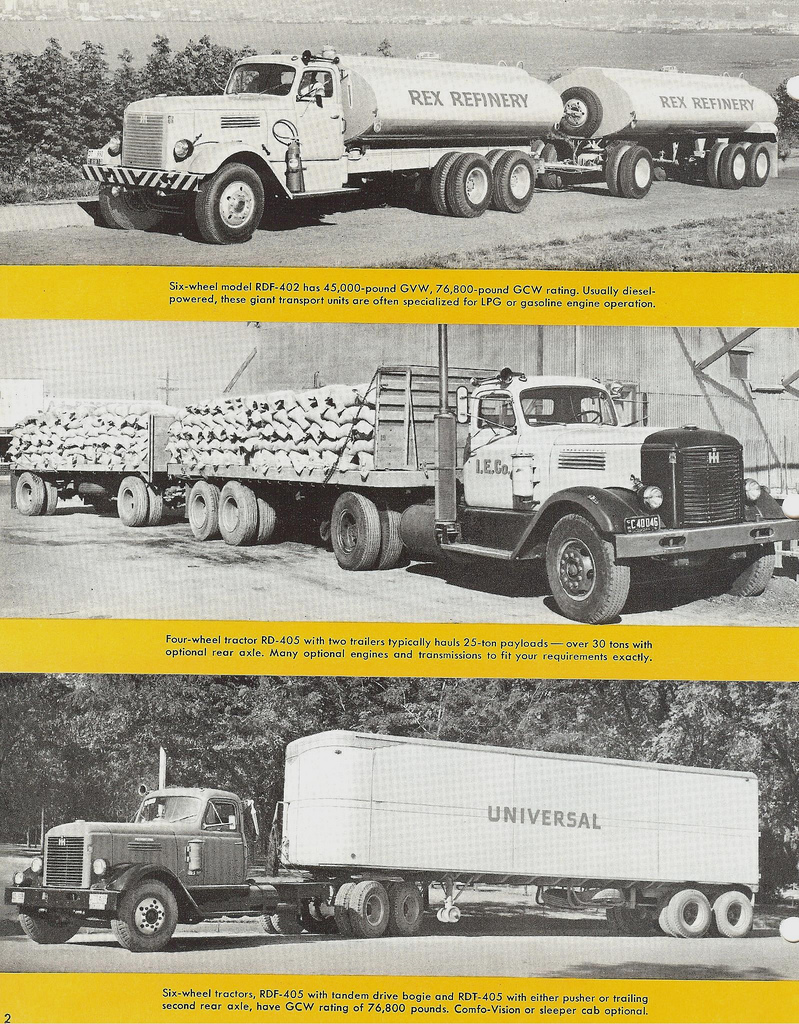

Navistar International Corporation (formerly International Harvester Company) is an American holding company that owns the manufacturer of International brand commercial trucks, IC Bus school and commercial buses, Workhorse brand chassis for motor homes and step vans, and is a private label designer and manufacturer of diesel engines for the pickup truck, van, hoes and SUV markets. The company is also a provider of truck and diesel engine parts and service.

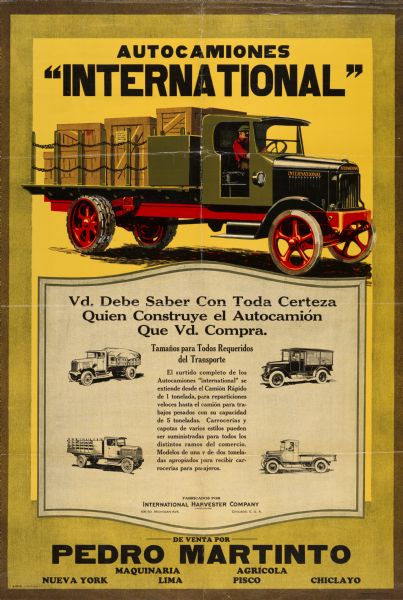

Headquartered in Lisle, Illinois, Navistar has 16,500 employees and an annual revenue of $10.775 billion (in 2013). The company’s products, parts, and services are sold through a network of nearly 1,000 dealer outlets in the United States, Canada, Brazil, and Mexico and more than 60 dealers in 90 countries throughout the world. The company also provides financing for its customers and distributors principally through its wholly owned subsidiary, Navistar Financial Corporation.

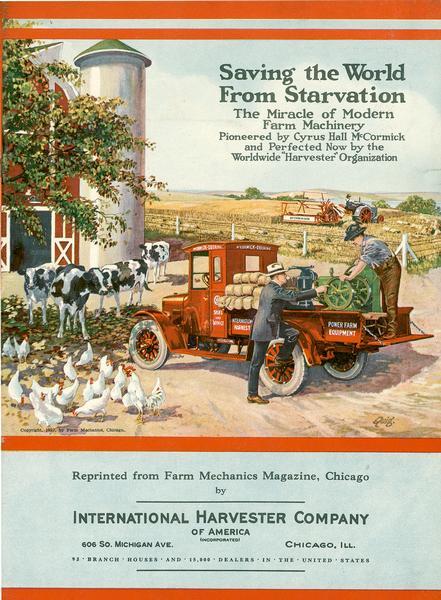

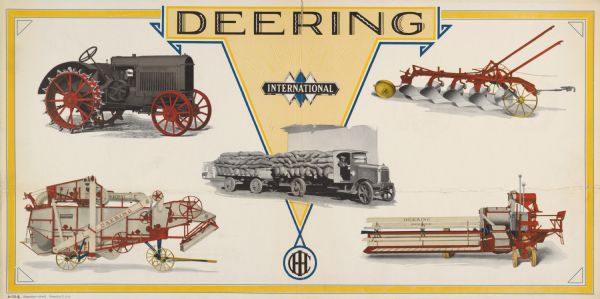

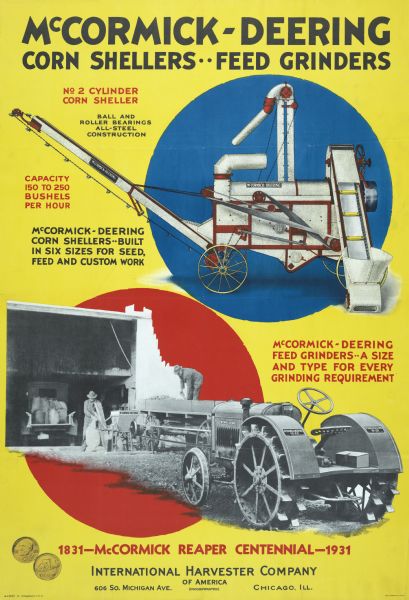

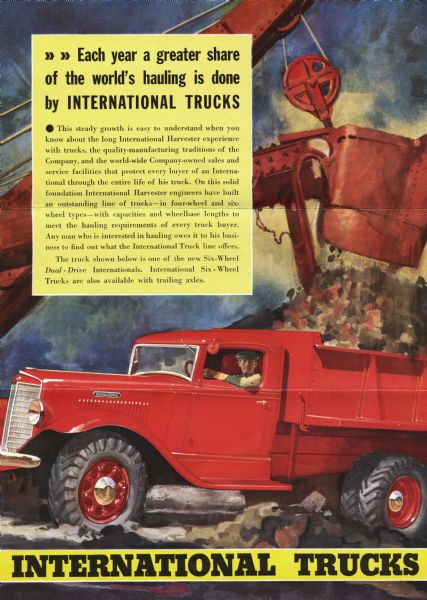

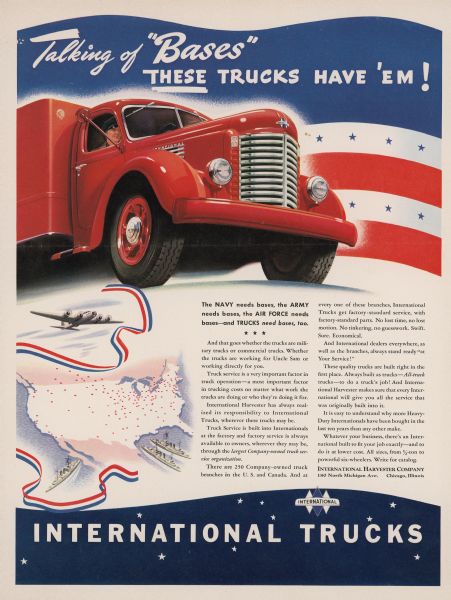

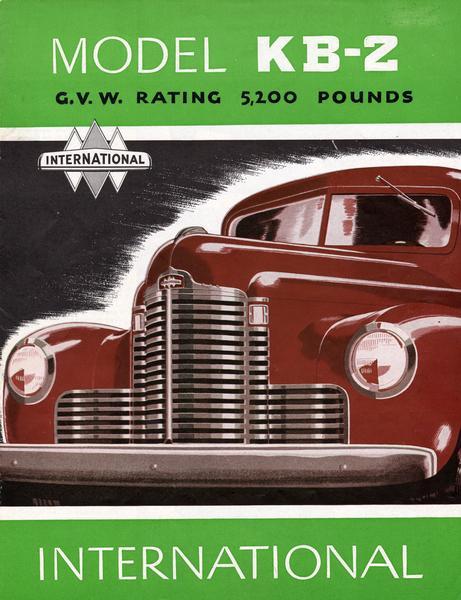

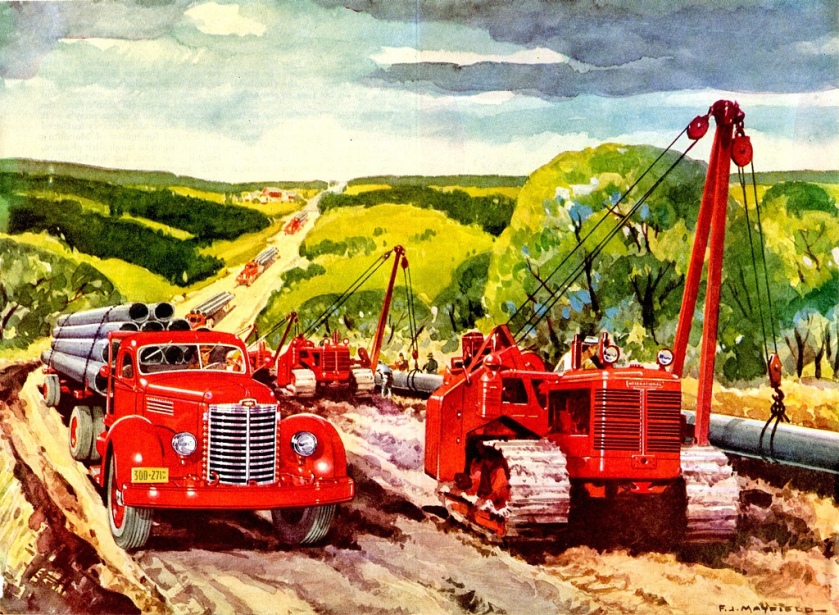

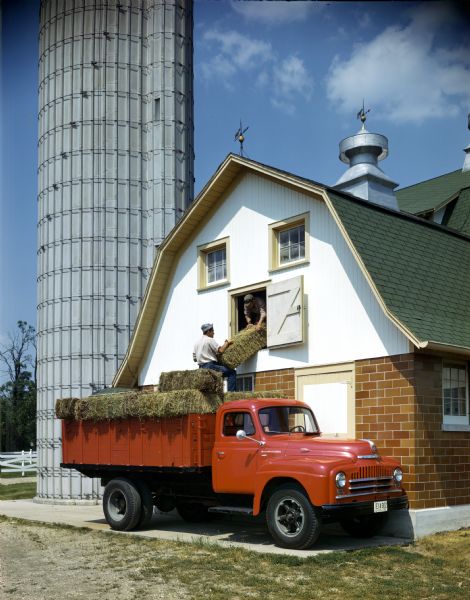

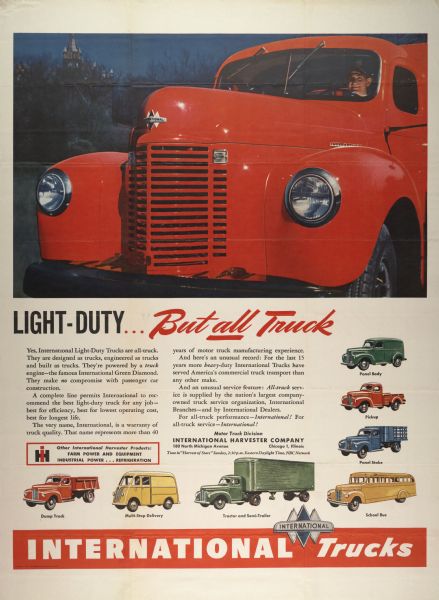

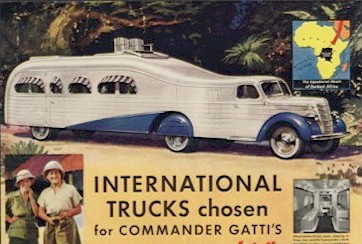

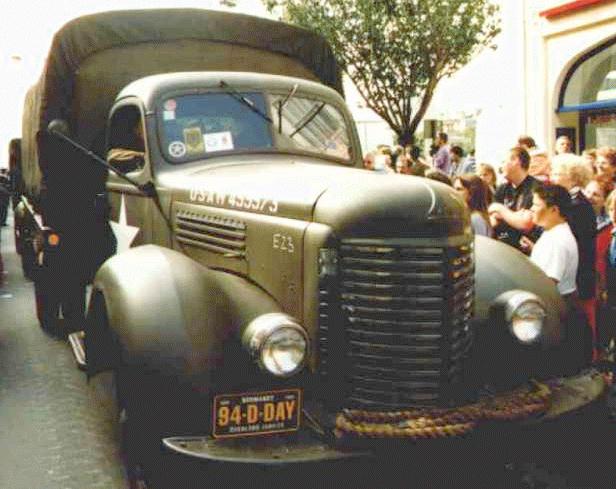

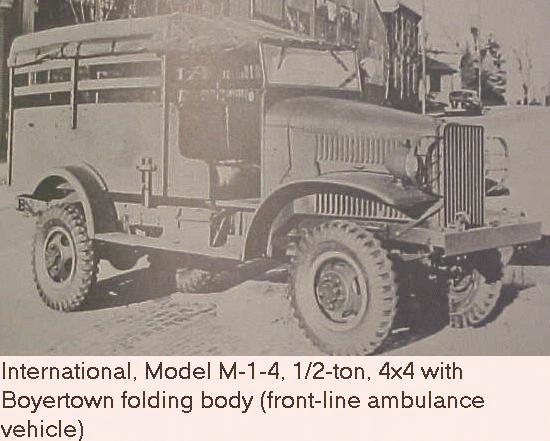

History

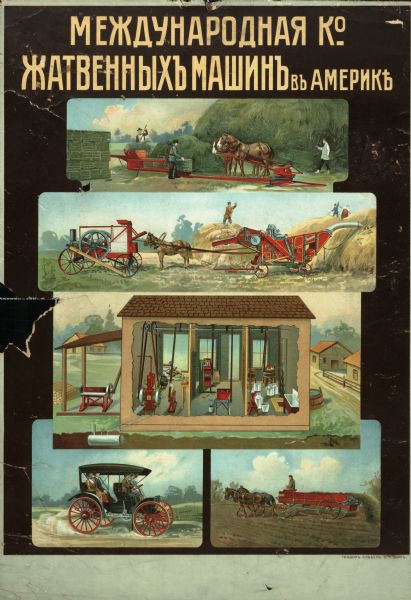

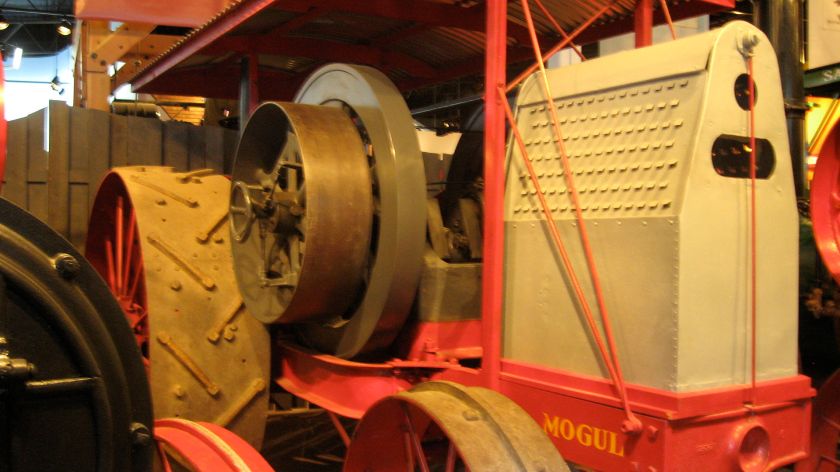

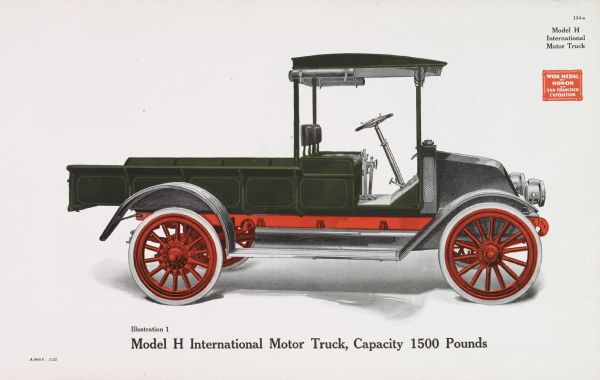

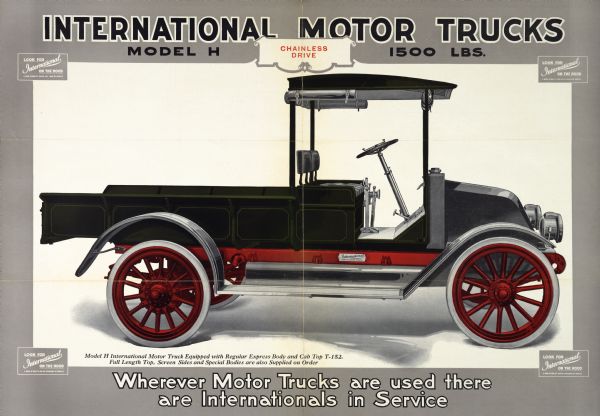

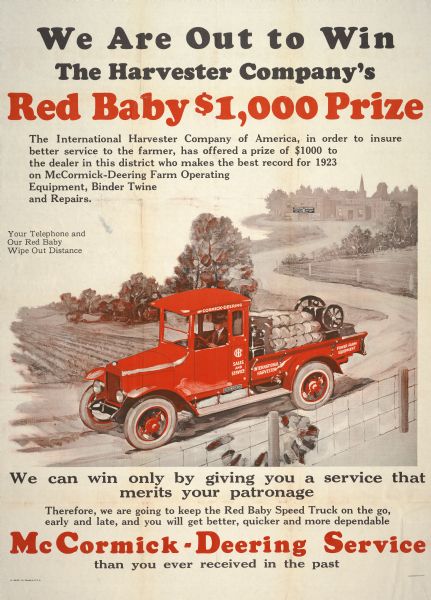

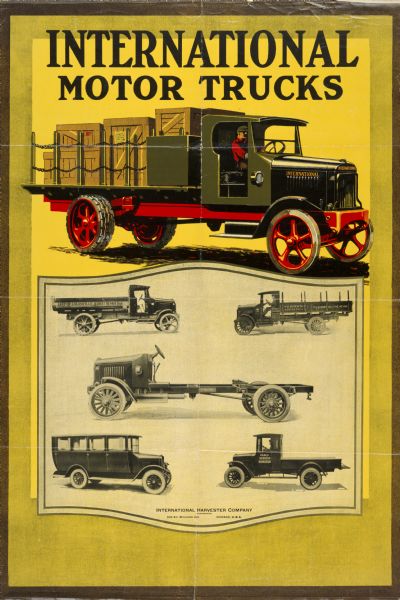

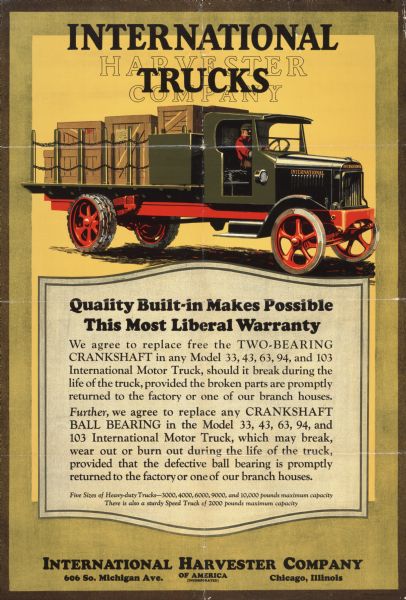

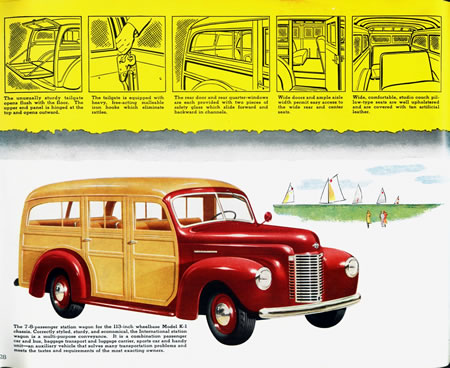

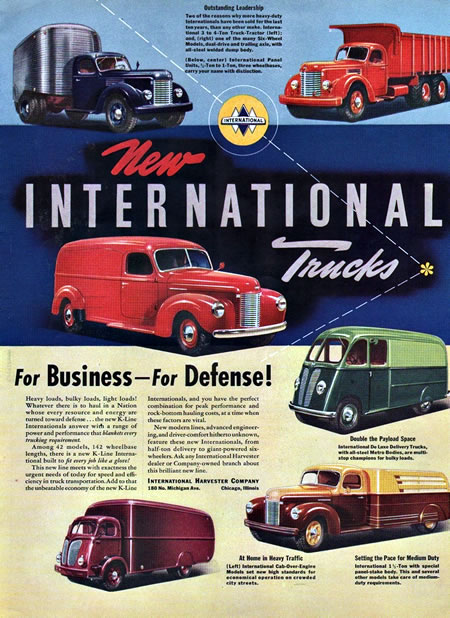

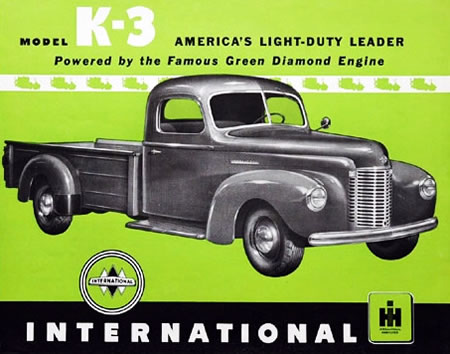

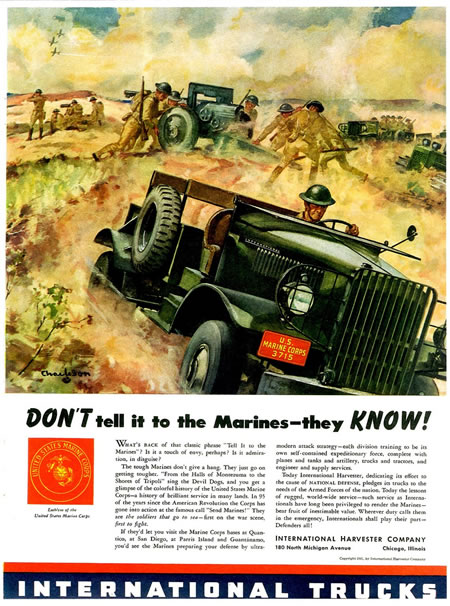

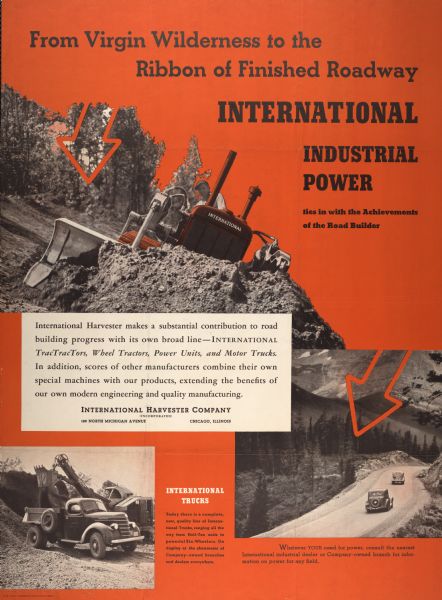

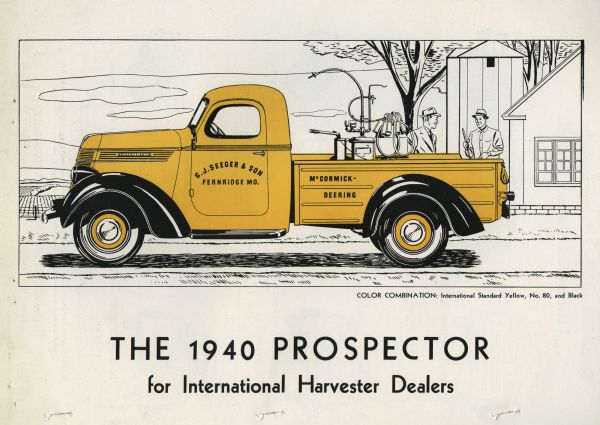

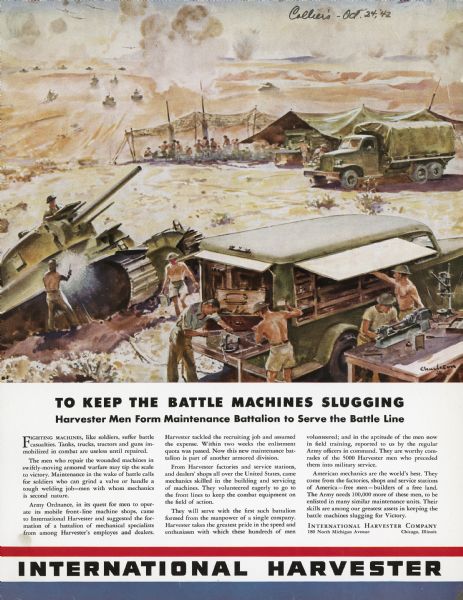

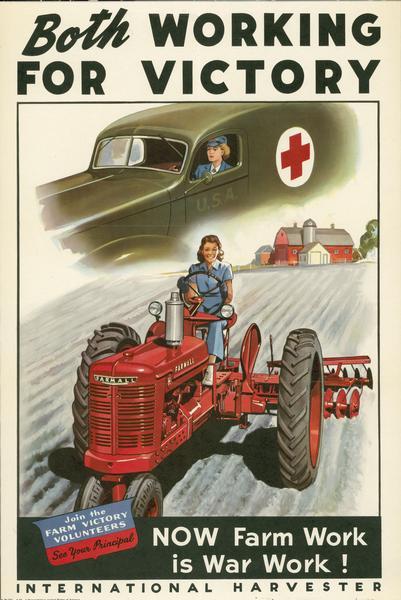

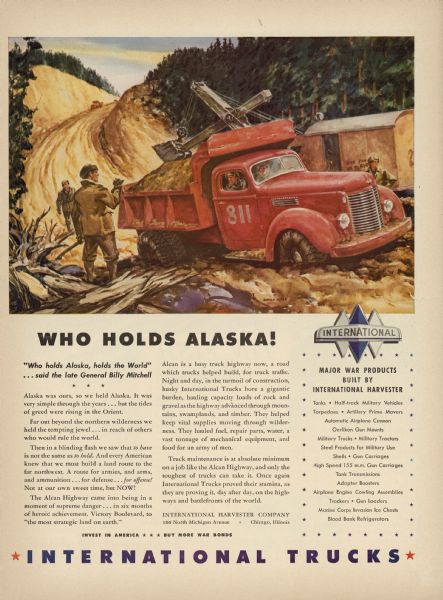

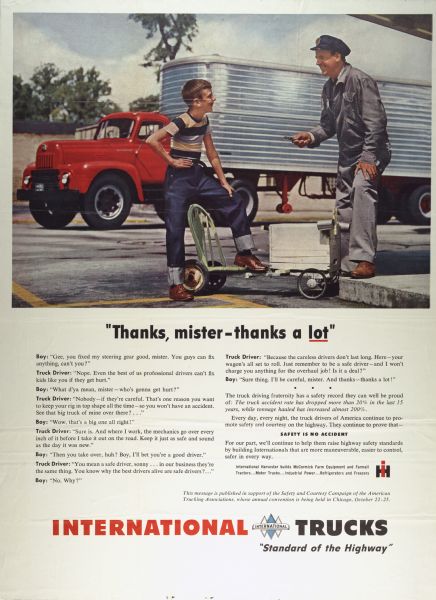

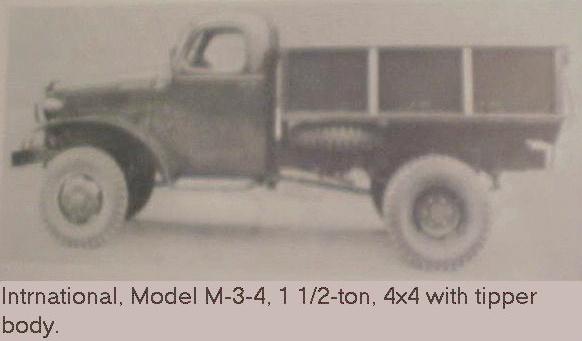

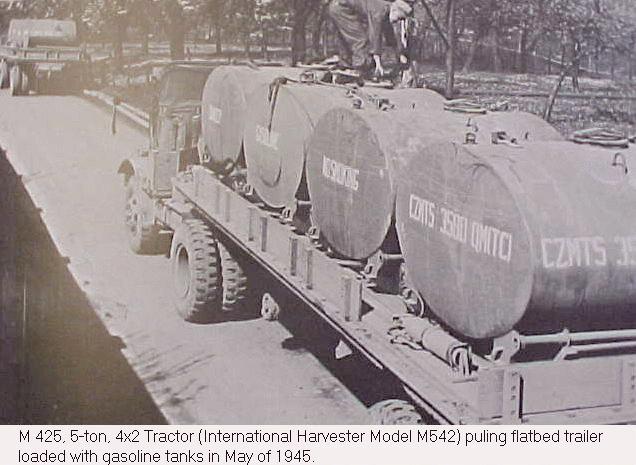

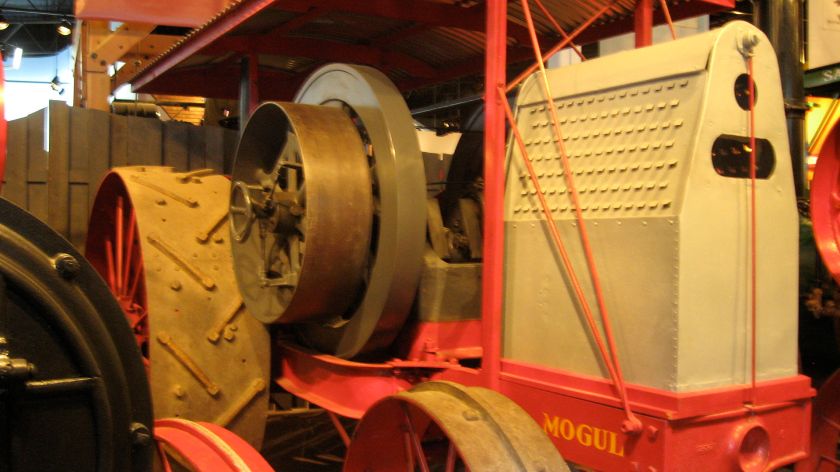

The merger of McCormick Harvesting Machine Company and the Deering Harvester Company in 1902 resulted in the formation of the International Harvester Company (IH) of Chicago, Illinois, which over the next three-quarters of a century evolved to become a diversified manufacturer of farming equipment, construction equipment, gas turbines, trucks, buses, and related components. During World War II, International Harvester produced the M-series of military trucks that served the Marine Corps and the U.S. Navy as weapons carriers, cargo transporters and light artillery movement. Today, Navistar produces International brand military vehicles through its affiliate Navistar Defense.

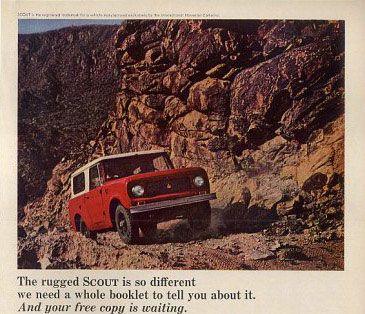

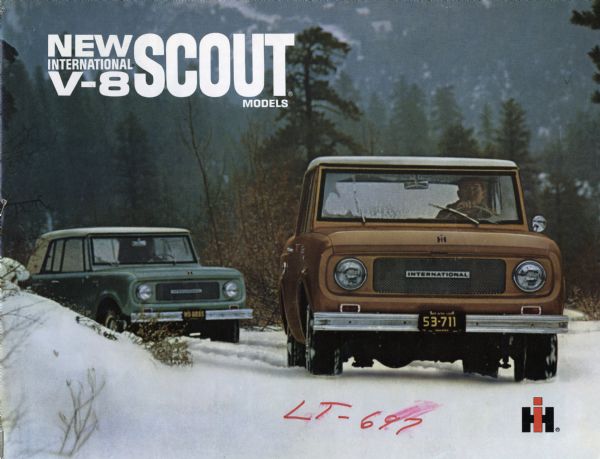

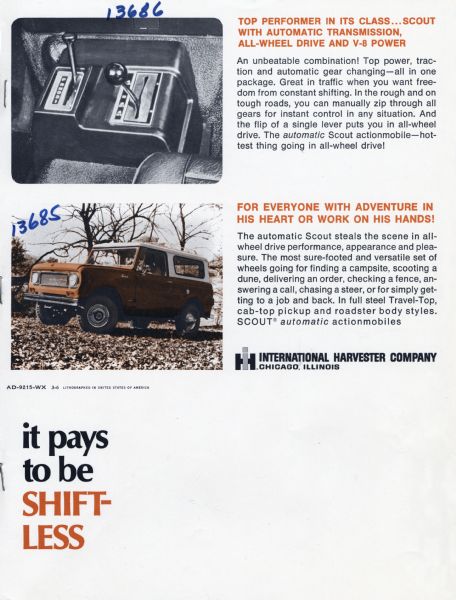

1986-1991: Transition from agricultural roots

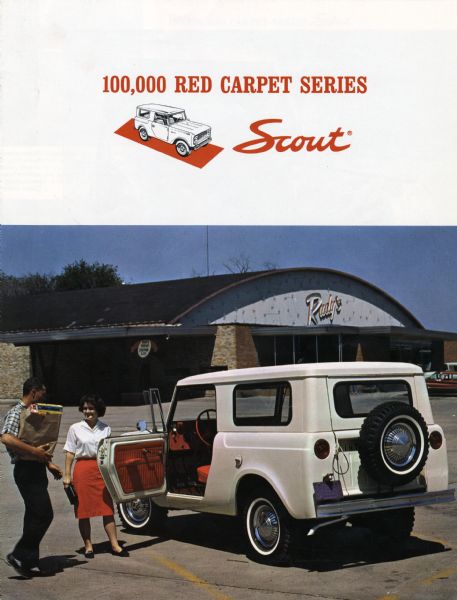

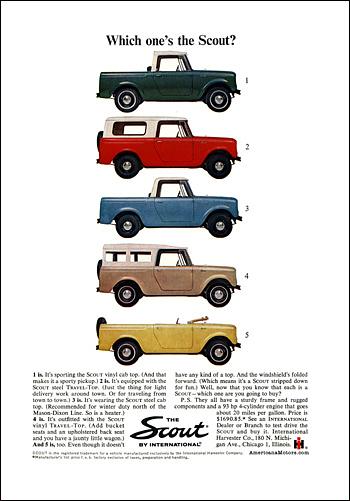

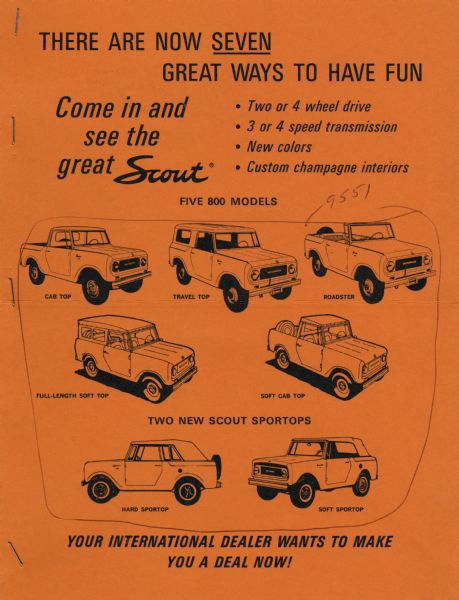

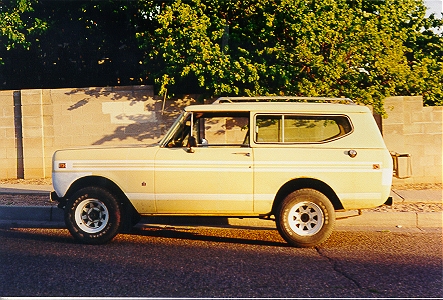

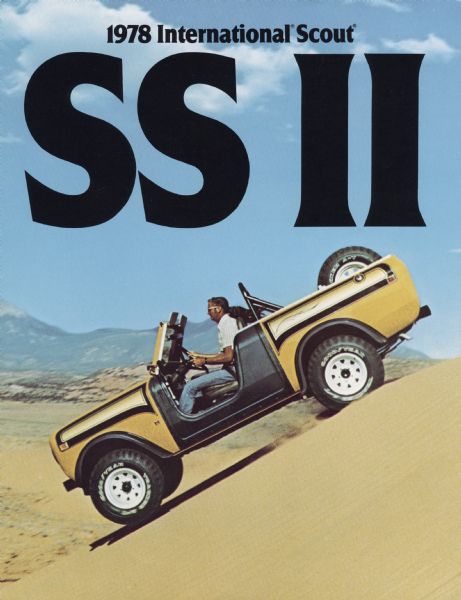

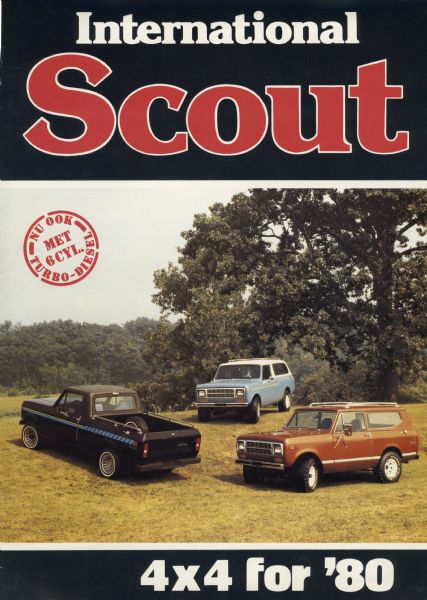

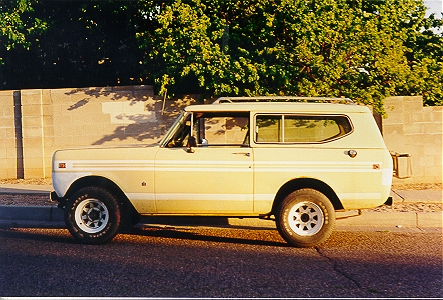

International Harvester fell on hard times during the poor agricultural economy in the early to mid-1980s and the effects of a long strike with the UAW over proposed work rule changes. IH’s new CEO, Donald Lennox, directed the management organization to begin exiting many of its IH’s historical business sectors in an effort to survive. Some of the sales of profitable business endeavors were executed to raise cash for short-term survival, while other divisions were sold due to lack of immediate profitability. During this period of questionable economic survival, in an effort to raise needed cash and to reduce losses, the management team led by Mr. Lennox at IH shed many of its operating divisions: Construction Equipment Division to Dresser Industries; Solar (gas turbines) Division to Caterpillar; Cub Cadet (lawn and garden equipment) to MTD Products and, lastly, the Agricultural Division to Tenneco, which merged it with their J.I. Case subsidiary. The Scout and Light Truck Parts Business was sold to Scout/Light Line Distributors, Inc. in 1991.

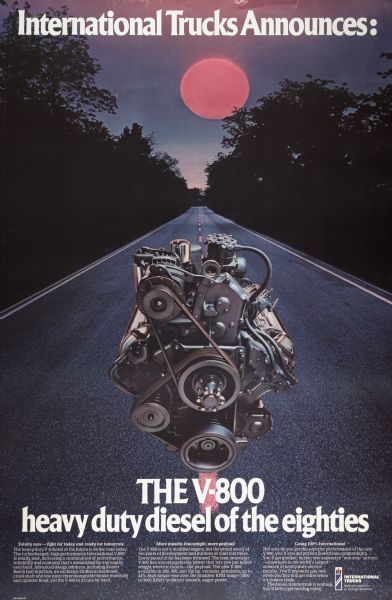

After the Agricultural Division sale in 1985, all that remained of IH was the Truck and Engine Divisions. The company changed its name in 1986 to Navistar International Corporation. (The International Harvester name and IH logo were assets of the Agricultural Division and consequently were part of the sale to Tenneco; the IH name and logo are still in use, having been incorporated into the Case IH brand name). In the early 1980s, IH developed a series of reliable large-displacement V8 diesel engines that were sold as an option for heavy-duty Ford 3/4-ton and 1-ton pickup trucks.

Navistar still uses the “International” brand in its diesel engine and truck product lines, and the brand name continues on in product lines of Navistar International’s International Truck and Engine Corporation subsidiary.

1990s-early 2000s: Rediversification

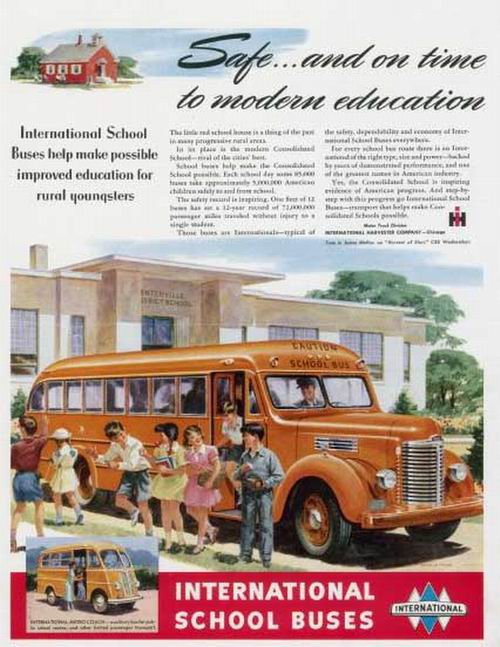

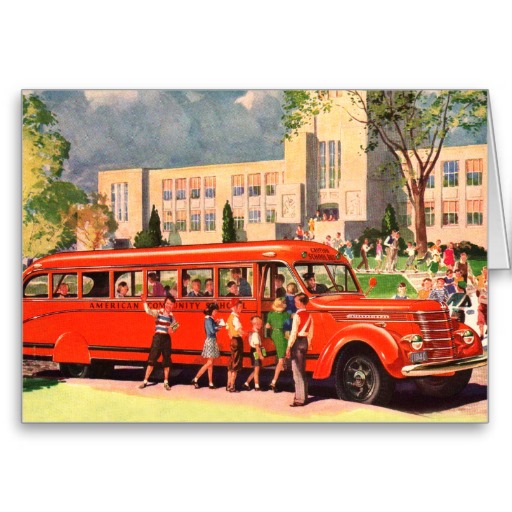

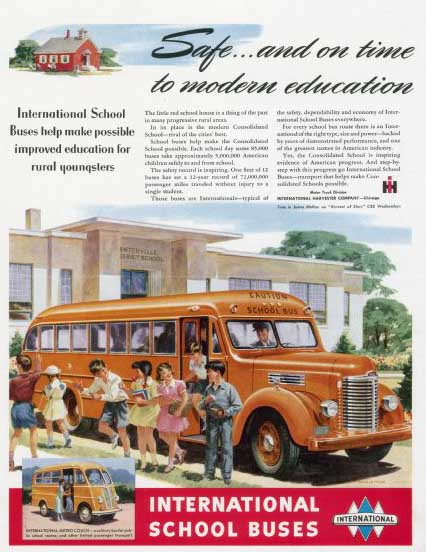

During the 1980s and 1990s, the popularity of diesel engines had made Navistar a leading manufacturer of bus chassis, particularly school buses. The company purchased one-third of American Transportation Corporation (AmTran), an Arkansas-based manufacturer in 1991, and the remaining two-thirds in April 1995. By becoming both a body and chassis manufacturer at the same time, Navistar gained significant market share in the industry. In 2002, AmTran was rebranded as IC (Integrated Coach) after a few months as International Truck and Bus.

After nearly a century of business in Chicago, Navistar announced its plans on 30 September 2000 to leave the city and relocate its corporate offices to west suburban Warrenville, Illinois. The company’s Melrose Park, Illinois plant is notable for a significant workplace shooting on February 5, 2001.

In 2004, Navistar re-entered the retail vehicle market for the first time since 1980. The International XT (Extreme Truck) pickup truck was a series of three pickup trucks. It was (by far) the largest pickup truck available for retail sale and two of the three versions (the CXT and RXT) were essentially

International Durastar medium-duty trucks fitted with pickup beds. The third version (the MXT) was essentially a street-legal version of a Navistar-designed military vehicle. The three XT trucks were sold until 2008.

Navistar-designed military vehicle. The three XT trucks were sold until 2008.

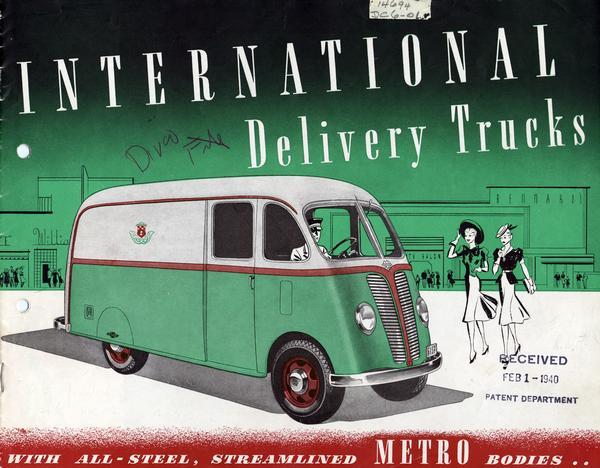

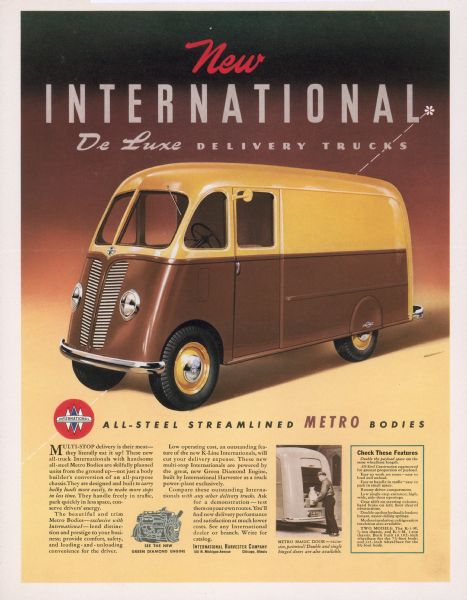

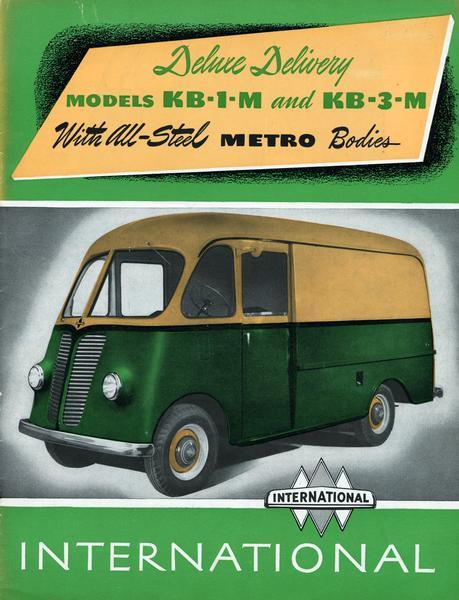

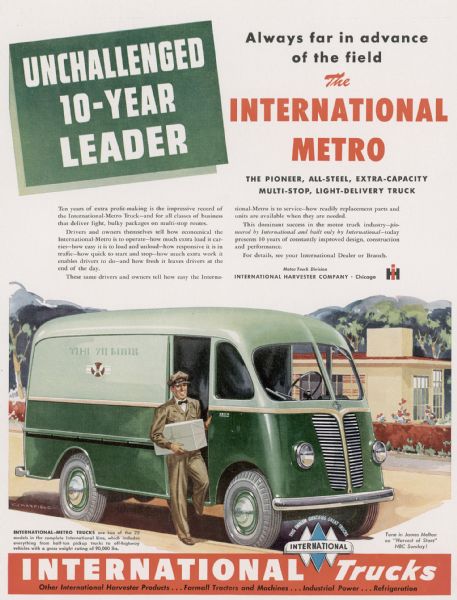

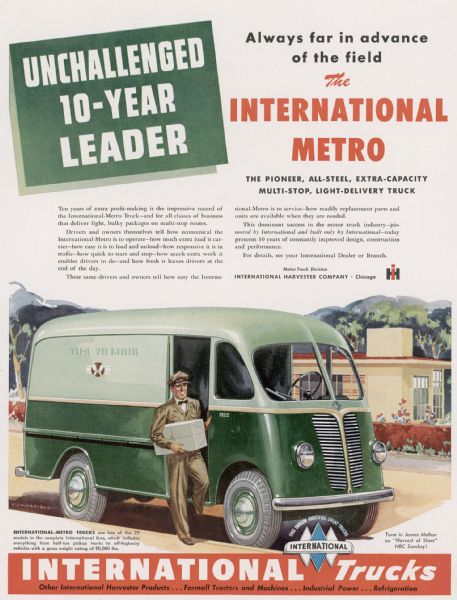

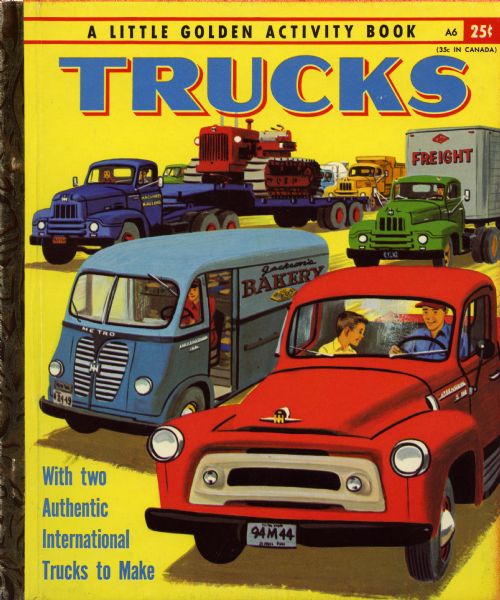

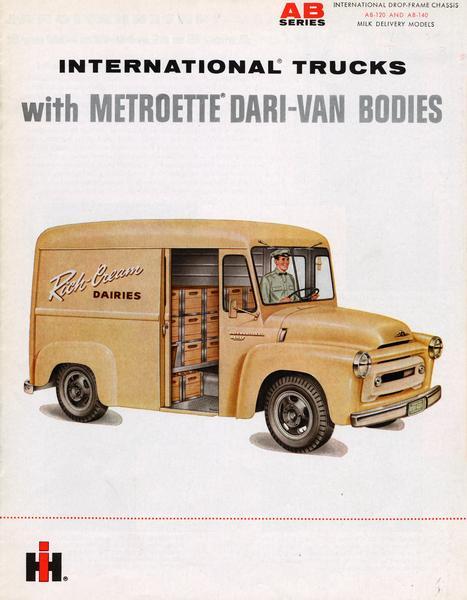

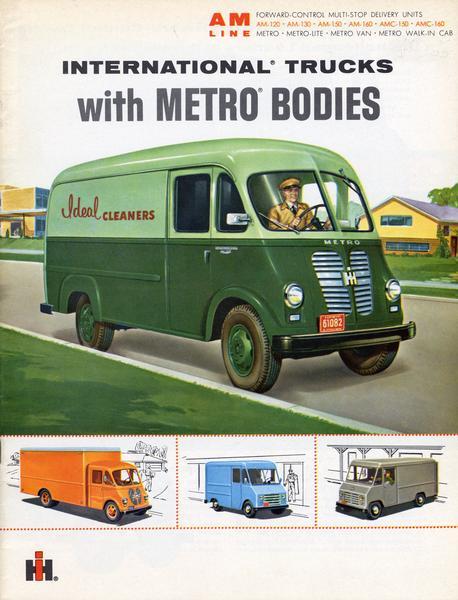

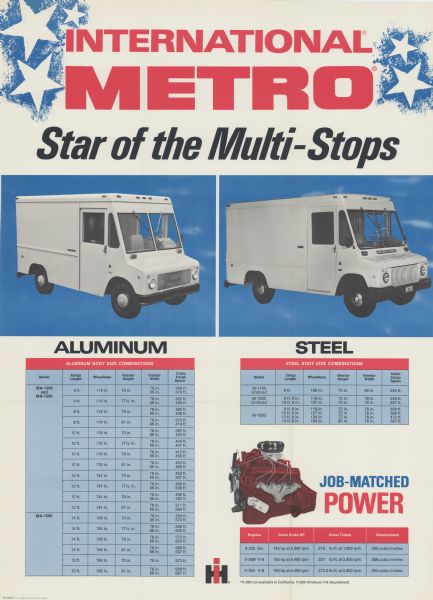

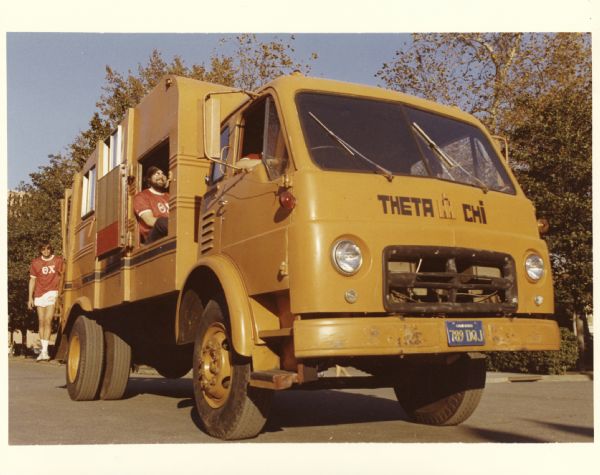

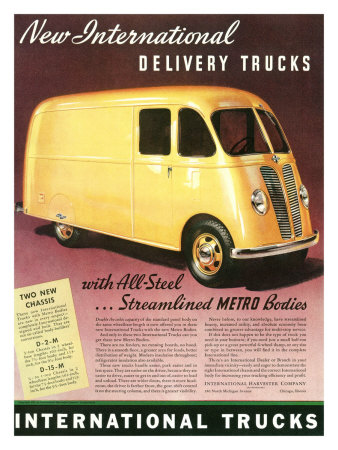

In 2005, Navistar purchased the Workhorse company (started in 1998 by investors who took over production and sales of General Motors’ popular P-series Stepvan chassis when GM dropped it), a manufacturer of step-van and motor home chassis, to seemingly re-enter the delivery van market. It appeared that the new subsidiary might also benefit by its association with a company whose history from the 1930s into the ’60s included the popular Metro van. For a short time Workhorse offered an integrated chassis-body product called MetroStar. In Sept. of 2012, Navistar announced the shut down of Workhorse and the closure of the plant in Union City, IN in order to cut costs.

Metro van. For a short time Workhorse offered an integrated chassis-body product called MetroStar. In Sept. of 2012, Navistar announced the shut down of Workhorse and the closure of the plant in Union City, IN in order to cut costs.

2006-2008

Accounting issues

In January 2006, the company declared it would not file its form 10-K annual report with the U.S. Securities and Exchange Commission on time. The delay was caused by the disagreement with its auditors, Deloitte and Touche, over complex accounting issues. In April, Navistar fired Deloitte, its independent auditor for 98 years, and hired KPMG to help restate earnings back to 2002 to fix accounting errors. On December 15, 2006, Navistar executives announced further delay of its restatement and 2006 results. The announcement prompted the New York Stock Exchange (NYSE) to announce the delisting of the company, after 98 years of trading, although the NYSE subsequently delayed the delisting pending an appeal by Navistar. However, Navistar was removed from the S&P 500 Index, and the NYSE eventually denied Navistar’s appeal and delisted the stock; it traded on the Pink Sheets until 30 June 2008, when it was relisted on the NYSE, under its previous ticker symbol, NAV, after catching up with its filings. Christopher Anderson, the Deloitte partner responsible for the 2003 audit, accepted a one-year suspension from public audits in 2008, and became the first individual to be fined by the PCAOB.

CEO Daniel Ustian agreed to surrender to Navistar shares worth $1.3 million, while former Chief Financial Officer Robert C. Lannert consented to repay $1.05 million, each sum reflecting monetary bonuses they had received during the restatement period, the SEC said. Four other company executives paid civil penalties without admitting liability.

In December 2014, Navistar disclosed more accounting problems. These involved out-of-period adjustments, which were corrections of prior period errors relating to product warranties. This resulted in a $36 million increase in Cost of Products Sold. In addition, a material weakness was disclosed. In the company’s annual 10K, they reported that weakness was “surrounding validation of the completeness and accuracy of underlying data used in the determination of significant accounting estimates and accounting transactions. Specifically, controls were not designed to identify errors in the underlying data which was used to calculate warranty cost estimates and other significant accounting estimates and the accounting effects of significant transactions.

In October 2003, Navistar CEO Dan Ustian announced the company would be forming a defense business unit in order to sell military vehicles. Navistar Defense would be led by Archie Massicotte, a 26 year veteran of the company. Ustian stated “This is a natural area of growth for International. We already have all the platforms that the U.S. military and other NATO countries could leverage for products and services.”

In 2007, Navistar’s International Truck and Engine Corporation became the first company to enter hybrid commercial truck production, with the International DuraStar Hybrid diesel-electrictruck.

International DuraStar Hybrid diesel-electrictruck.

Navistar Defense LLC is the prime supplier of MRAP armored vehicles to the US military. The

MRAP armored vehicles to the US military. The  Navistar 7000 series has been fielded by the Canadian Forces for domestic operations. In 2005, the U.S. Army ordered 2,900 7000-MVs for the Afghan National Army and Iraqi Ministry of Defense and an additional order of 7,000 was added in 2008.

Navistar 7000 series has been fielded by the Canadian Forces for domestic operations. In 2005, the U.S. Army ordered 2,900 7000-MVs for the Afghan National Army and Iraqi Ministry of Defense and an additional order of 7,000 was added in 2008.

Navistar Defense also has a small Canadian branch, named Navistar Defence Canada.

Navistar Defense reported sales of $3.9 billion in 2008 and $2.8 billion in 2009.

In October 2009, the company entered into a strategic agreement with Czech-based company Tatra to jointly develop, produce and market new military vehicles.

In December 2009, analysts were skeptical of the company’s long-term potential. “Navistar came out of nowhere and became a big player with MRAP, in what was a short-term program,” said Dean Lockwood, an analyst at Forecast International Inc., a Connecticut-based defense consultant. “They didn’t prove themselves to be a long-term major player.”

In 2010, Navistar Defense’s sales were $1.8 billion. The company’s 2010 Annual 10K report stated “we continue to expect that over the long term our military business will generate approximately $1.5 billion to $2 billion in annual sales.”

In 2011, Navistar Defense’s sales were $2.0 billion.

In 2012, Navistar Defense reported $1.0 billion in sales. Business Insider ranked Navistar Defense at 22 in the top 25 US defense companies.

In 2013, Navistar Defense reported $543 million in sales. In the company’s 10K filing, they projected military sales to continue to decline, citing U.S. budgetary constraints.

In 2014, Navistar Defense reported $149 million in sales. The company projected 2015 military sales to be slightly higher due to recent contract awards relating to the government’s MRAP fleet.

Contract awards, losses and other events

On August 22, 2012, Navistar Defense lost their bid for the Engineering, Manufacturing & Development (EMD) contract worth $187 million for the Army and Marine Corps’ Joint Light Tactical Vehicle (JLTV) program. Navistar had proposed its Saratoga vehicle for the competition. On Friday August 28, 2012, Navistar filed a protest with the Government Accountability Office (GAO), but pulled their protest on Tuesday, September 4, 2012.

On June 20, 2013, Navistar Defense idled production at their West Point, MS production plant. 80 workers were notified that July 5, 2013 would be their last day. West Point was best known for manufacturing MRAP vehicles. The company cited sequestration, the drawdown in Afghanistan and a challenging environment in the defense industry as factors.

On August 22, 2013, Navistar Defense lost their bid for the Ground Mobility Vehicle (GMV) 1.1 contract, potentially valued at $562 million. Navistar had proposed its Special Operations Tactical Vehicle (SOTV) for the competition. On Tuesday September 1, 2013, Navistar Defense and AM General filed a protest. On December 19, 2013, the Government Accountability Office (GAO) denied Navistar and AM General’s protests.

In January 2014, the Pentagon announced they had notified allies of their intent to give away or scrap 13,000 used MRAPs. This was due to the war in Afghanistan winding down, the military wanting a lighter vehicle and high cost to ship them from the middle east back to the U.S. Recipients have included various police departments and some universities. Navistar Defense built 9,000 of the 27,000 vehicles bought by the Pentagon. Giving away the MRAPs was seen as a blow to Navistar Defense’s parts sales.

In December 2014, Navistar Defense lost their bid for the Engineering, Manufacturing Development (EMD) contract for the Armored Multi-Purpose Vehicle (AMPV). BAE was awarded the $382 million contract on December 23, 2014.

Navistar Defense lost their bid for Canada’s Department of National Defence (DND) MSVS (Medium Support Vehicle System) Project – SMP (Standard Military Pattern) vehicles contracts. They proposed their ATX8 vehicle as part of an agreement with Czech-based company Tatra. The contract was for acquisition and in-service support (ISS) of a fleet of up to 1,500 SMP vehicles, up to 150 Armour Protection Systems (APS) kits, and 300 Load Handling System (LHS) trailers. Competitors include Oshkosh (MTVR), BAE Systems (FMTV), Daimler AG (Zetros), Renault Trucks (Kerax 8×8) and Rheinmetall/ MAN (HX77 8×8). A contract award decision is expected in June 2015. On July 16, 2015, Canada awarded the Acquisition and In Service Support contracts to Mack Defense, LLC (Renault Trucks).

On July 25, 2014, the DOD awarded a $27.6 million modification to an existing contract to acquire mine-resistant, ambush-protected hardware kits to upgrade MaxxPro Dash and long-wheel base ambulances to their final configuration. Estimated completion date is May 30, 2015.

On August 27, 2014, the DOD awarded a $38 million contract to Navistar Defense to restore MRAP Maxx Pro Dash vehicles to “like-new” standards. The DOD reported that Navistar was the only bidder. The work includes adding independent suspension systems and replacement of mandatory parts, with an estimated completion date of June 30, 2016. Work will be performed in West Point, MS.

In September 2014, Navistar Defense announced they would hire 200 workers and re-open operations at their West Point, MS production plant. West Point had been idle since June 2013 due to sequestration, the drawdown in Afghanistan and declining orders.

In September 2014, amidst numerous divestitures, Navistar Inc. CEO Troy Clark gave Navistar Defense a vote of confidence, noting that the military business unit would be retained. In a September 2014 interview with Reuters he said “it’s not a billion-dollar growth opportunity, but it’s not something that’s bleeding off the future fortunes of our company.”

On October 14, 2014, Navistar Defense was awarded a $9.2 million firm-fixed price foreign military sale (FMS) contract to Jordan for one hundred 4-ton 4×4 cargo trucks and twenty days of operator and maintenance training. Work will be performed in New Carlisle, Ohio with an estimated completion date of May 20, 2015. Bids were solicited via the internet with nineteen received.

On February 2, 2015, Navistar Defense was awarded a $15,381,152 firm-fixed-price contract with options for eight MRAP MaxxPro Hardware Kits to support MaxxPro vehicle standardization and reset. Work will be performed in Lisle, Illinois, with an estimated completion date of July 16, 2016. Bids were solicited via the Internet with one received. Fiscal 2015 other procurement (Army) funds in the amount of $15,381,152 are being obligated at the time of the award. Army Contracting Command, Warren, Michigan, is the contracting activity (W56HZV-15-C-0070).

On March 18, 2015, Navistar Defense was awarded a $83,424,223 cost-plus-fixed-fee multi-year contract for system technical support and system sustainment technical support for MRAP MaxxPro vehicles. Funding and work location will be determined with each order with an estimated completion date of March 31, 2019. One bid was solicited with one received. Army Contracting Command, Warren, Michigan, is the contracting activity (W56HZV-15-D-0037).

On April 13, 2015, Navistar Defense was awarded a $17,522,057 firm-fixed-price contract with options to procure seven Mine Resistant Ambush Protection MaxxPro Dash hardware kits for MaxxPro vehicle standardization and reset. Work will be performed in Lisle, Illinois, with an estimated completion date of Dec. 31, 2015. One bid was solicited with one received. Fiscal 2014 and 2015 other funds in the amount of $17,522,057 are being obligated at the time of the award. Army Contracting Command, Warren, Michigan, is the contracting activity (W56HZV-15-C-0092).

On April 30, 2015, Navistar Defense was awarded a $31,199,783 modification (P00004) to contract W56HZV-14-C-0102 for reset and upgrade of the MRAP (mine-resistant ambush protected) family of vehicles to Code-A standards. Work will be performed in West Point, Mississippi, with an estimated completion date of July 31, 2016. Fiscal 2013 and 2015 other procurement (Army) and operations and maintenance (Army) funds in the amount of $17,990,419 were obligated at the time of the award. Army Contracting Command, Warren, Michigan, is the contracting activity.

In April 2015, Navistar Defense President Bob Walsh resigned. On May 19, Kevin Thomas was promoted to President.

2001-Present: Failed engine strategy, layoffs, consolidation and turnaround

Failed Engine Strategy

In 2001, then CEO Dan Ustian faced numerous EPA regulations to reduce the amount of nitrogen oxides and soot emanating from diesel engines. Despite the change in the compliance arena, the regulations would not begin to be phased in until 2007, with full implementation slated for 2010.

Ustian had multiple engineering paths available. Among them were Selective Catalytic Reduction (SCR), Exhaust Gas Recirculation (EGR) or the use of nitrogen oxide absorbers. All required more engineering and development to achieve compliance. Ustian believed truckers did not want to bother with an extra tank of fluid aftertreatment. As a result, he convinced the company to spend $700 million to fund EGR development.

On October 31, 2007, Navistar formally announced their intent to move forward with EGR as the company’s strategy. The company statement included Ustian mentioning “I have publicly been an advocate of customer friendly emissions control solutions which do not add additional costs to our truck and bus customers. While SCR is a means to achieve the NOx reduction requirement for 2010, it comes with a steep cost to our customers. Our ability to achieve our goals without adding customer cost and inconvenience is a competitive advantage for International.”

On November 24, 2008, Navistar revealed it would use EPA Credits in order to comply with the 2010 legislation.

In February 2009, Ustian touted the benefits of EGR technology as a key differentiator for the company’s engines. However, by now, the rest of the industry had chosen to use the compliant SCR technology. Ustian disagreed with SCR, saying “the other thing that EGR avoids is the risks of an SCR strategy. Read the label on this and it will show you that there are challenges with keeping control of using this technology: ‘Store between 23 degrees and 68 degrees.’ So essentially it says you can’t throw it outside. You can’t operate it in conditions above 85 [degrees] or below 12 [degrees]. You can, but, it will put the burden onto the customers.”

Non-Conformance Penalties

The EPA recognized Navistar’s imminent non-compliance and created a system of Non-Conformance Penalties (NCPs) that included a $1,919 dollar fine for every non-compliant engine that Navistar sold. To bridge the gap, Navistar began using EPA credits it had previously earned for being compliant in lieu of paying fines. In August 2012, Navistar stated they would run out of EPA credits soon. Only days earlier the EPA announced increased new penalties of $3,744 per engine.

In March 2009, Navistar sued the EPA, claiming that the agency’s guidance documents for SCR implementation were invalid because they were adopted without a public process and with input only from the SCR engine makers. Navistar and the EPA settled the lawsuit a year later.

Further masking the EGR problem were high military sales. In the company’s 2010 10K report, Navistar cited orders for MRAPs as offsetting flat commercial sales due to the recession.

Move to Lisle, IL

In September 2010, despite uncertainty over EGR and a sluggish economy, Navistar leadership revived an effort to relocate the company headquarters from Warrenville, IL, to nearby Lisle, IL. The new headquarters was expected to retain or create 3,000 permanent jobs and about 400 construction jobs. Navistar President Dan Ustian said roughly 500 engineers would be hired immediately. Navistar aimed to invest $110 million in the 1.2 million-square-foot Lisle campus, which would include product development. The state gave Navistar incentives of nearly $65 million, including tax credits.

In March 2011, Navistar announced the move to Lisle. Renovations were completed in the fall, but the company gradually moved from Warrenville to Lisle in summer 2011. “You can’t build a campus like this anywhere for anywhere near the price we paid for this, and even though you might get more incentives, when you look at the whole picture, you really can’t beat it,” said Don Sharp, Navistar vice president.

In 2011, Navistar began phasing out its Truck Development and Technology Center (TDTC) in Fort Wayne, Indiana. In early December 2011, the company laid off 130 employees, mostly engineers and designers who were United Auto Workers members. In total, 300 out of 1,400 Fort Wayne employees eventually accepted offers to relocate to Illinois. The other 1,100 workers either retired or chose to remain in Indiana and find work elsewhere. The cost to move employees and consolidate operations was estimated to be $75 million. The only Navistar employees remaining after December 2012 were 20-25 people manning the company’s test track on Oxford Street. In late July 2015, the TDTC closed and the remaining workers were let go.

In January 2012, the EPA adopted an interim final rule that allowed Navistar to continue selling the engines subject to NCPs. Several Navistar competitors sued, and in June 2012 the same appeals court ruled that EPA’s interim rule was invalid because it did not give the public notice and an opportunity for comment.

In the mean time, Navistar’s EGR decision had led to significant reliability and quality problems. Truck drivers began losing trust and confidence as Navistar vehicles were breaking down frequently. Consequently, they abandoned Navistar trucks in favor of competitor’s trucks.

Tension Mounts

In June 2012, speculation mounted about a possible takeover of the struggling truck maker. This came as hedge fund MHR Fund Management LLC disclosed a 13.6% stake in the company, slightly higher than billionaire activist investor Carl Icahn’s 11.9% stake. As a result, Navistar adopted a poison pill defense. If the plan were triggered by an outside investor taking a stake of 15 percent or more in the company, then Navistar would issue its shareholders rights that would let them buy new common stock in the company at a discount of 50 percent: For each share held, the investor could buy $280 worth of new shares for $140. The investor who took the 15 percent stake or more would not have the right to buy additional shares.

In August 2012, Navistar announced it would use Cummins engines and SCR technology. After 37 years with the company, Dan Ustian retired immediately in August 2012 and left his position on the board as well. Former Textron CEO Lewis Campbell was named interim CEO and Troy Clarke was promoted to Chief Operating Officer. Ustian’s severance package began at $7.9 million. The company’s proxy statement during this time estimated the total package to be $14.6 million, contingent on a share price of $42.07 on Oct. 31, 2011, the end of the company’s fiscal year.

On September 9, 2012, billionaire and key stock holder Carl Icahn sent an open letter to Navistar’s board, blasting them for “abysmal business decisions” and “poor corporate governance.” Icahn noted from 2009-2012, that “this Board has authorized spending shareholder money on lawsuits against suppliers, competitors and regulators, marketing plans to convince customers that non-compliant engines are actually compliant, accumulating non-core assets such as a Recreational Vehicle manufacturer, and a “gold-plated” corporate headquarters that cost over $100 million. The one thing this Board refused to spend money on was a back-up plan involving the industry standard technology Navistar now must rely on.”

In a September 2012 interview, Cummins CEO Tom Linebarger said, “all we did was act nice to them (Navistar) even when they didn’t talk nicely about us,” he smiled, recalling harsh comments that Navistar executives had made about SCR being used by all its competitors.

In October 2012, Chief Product Officer Deepak Kapur stepped down, followed by Group Vice President of Product Development Ramin Younessi in December 2012. CIO Don Sharp also left the company in April 2013.

Layoffs and consolidation

August 2012 featured a Voluntary Separation Program (VSP) as well as involuntary layoffs. This was due to the failed engine strategy, rising warranty costs and declines in commercial and military sales. The company let go 500 employees and in September 2012, announced plans to lay off 200 more salaried employees.

In addition, the company announced it would close its Garland, Texas manufacturing facility by mid-2013, resulting in the loss of 900 jobs.

In March 2013, Navistar announced that interim CEO Lewis Campbell would step down and COO Troy Clarke would be named CEO and Chairman of the Board. Jack Allen was named COO. In June 2013, CFO A.J. Cederoth stepped down and James M. Moran, Navistar senior vice president and treasurer, would act as interim CFO until a successor could be found. In late June 2013, former General Motors executive Walter Borst was named Executive VP and CFO.

In September 2013, Navistar announced it would cut 500 more jobs amid a larger than expected third quarter loss. Navistar reported a slower than expected return to profitability due to large market share losses, declining sales and weak market conditions.

In May 2014, a third round of lay-offs in as many years occurred at the corporate headquarters as part of ongoing cost cutting measures.

On July 31, 2015, Navistar ceased operations and laid off the remaining 15 employees at the Truck Development and Technology Center (TDTC) in Fort Wayne, Indiana.

Cost-cutting and divestitures

As part of the turnaround plan, Navistar executives cut costs aggressively. They cut SG&A costs by 16% in 2013 and cut product development spending by 24%. Interim CEO Lewis Campbell’s priorities included a focus on quality, reducing the company’s cost structure and paring back its product line.

Navistar also sold several businesses that it deemed were not providing enough of a Return On Invested Capital (ROIC). Among them were their Monaco RV business as well as Workhorse Chassis. They also exited their joint venture with Mahindra and sold off their E-Z Pack unit, which made bodies for garbage trucks, as well as its Continental Mixer unit, which made concrete mixers, for prices the company characterized as “not material.”

In January 2014, Forbes reported several key challenges facing Navistar, which include declining military sales, a pension plan underfunded by $2.7 billion, two self-disclosed weaknesses in accounting practices and a new collective bargaining agreement for the company’s 6,000 full and part-time workers who are represented by labor unions.

In February 2014, Navistar announced it would move some engine production operations from Huntsville, AL, to Melrose Park, IL by summer 2014. The move eliminated 280 jobs in Alabama and saved an estimated $22 million. Navistar said it would keep two other diesel engine plants operating in Huntsville.

In September 2014, Navistar reported its best quarter in years. It announced a third quarter net loss of $2 million, or $0.02 per diluted share, compared to a third quarter 2013 net loss of $247 million, or $3.06 per diluted share. It was also in September that CEO Troy Clarke announced that the company’s biggest divestitures were complete, and that the focus would now be on regaining lost market share.

On November 6, 2014, leadership changes continued at Navistar, with Executive VP and COO Jack Allen retiring immediately. Rather than hire a new COO, CEO Troy Clarke split the COO duties among three other executives.

Legal issues and struggle for profitability

In December 2014, the United States Judicial Panel on Multidistrict Litigation ordered that 13 of 14 civil lawsuits brought against Navistar for MaxxForce engines would be consolidated into one case. The consolidated lawsuits say Navistar’s use of Advanced Exhaust Gas Recirculation emission control system, or EGR, was defective and resulted in repeated engine failures and frequent repairs and downtime.

On December 16, 2014, Navistar reported a larger than expected 4th quarter net loss of $72 million. While sales rose 9 percent to $3 billion, the company cited restructuring and warranty costs as the main reasons for the loss. A day earlier, the company announced it would be closing its engine foundry in Indianapolis, resulting in the loss of 100 jobs and costing $11 million. The company estimated annual savings of $13 million in operating costs.

In March 2015, Navistar reported a first quarter 2015 net loss of $42 million, or $0.52 per diluted share, compared to a first quarter 2014 net loss of $248 million, or $3.05 per diluted share. Revenues in the quarter were $2.4 billion, up $213 million or 10 percent, versus the first quarter of 2014. The higher revenues in the quarter were driven by a 17 percent year-over-year increase in chargeouts for Class 6-8 trucks and buses in the United States and Canada. This included a 42 percent increase in school buses; a 25 percent increase in Class 6/7 medium trucks; a 7 percent increase in Class 8 heavy trucks; and a 5 percent increase in Class 8 severe service trucks. Higher sales in the company’s export truck operations also contributed to the increase, partially offset by a decrease in used truck sales. The company finished the first quarter with a 27 percent year-over-year increase in order backlog for Class 6-8 trucks.

On June 4, 2015, Navistar reported a second quarter net loss of $64 million, or 78 cents a share, compared with a year-earlier loss of $297 million, or $3.65 a share. Revenue fell to $2.69 billion from $2.75 billion. Analysts had expected a loss of 18 cents a share and revenue of $2.82 billion.

On June 9, 2015, Navistar named Jeff Sass as the new Senior VP of North American Truck Sales. Sass previously worked 20 years for rival Paccar.

On June 12, 2015, Mark Rachesky’s MHR Fund Management LLC disclosed a 6% increased stake in Navistar, up to 15,446,562 shares. The firm now owns 18.9% of Navistar.

In July 2015, the Environmental Protection Agency filed a civil lawsuit against Navistar seeking $300 million in fines over its use of non-compliant engines in its 2010-model trucks – engines that did not meet the agency’s exhaust emission standards. “Because (Navistar) completed manufacturing and assembling processes for the subject engines in 2010 … each and every engine was ‘produced’ in 2010 and is therefore not a model 2009 engine,” the complaint said. Navistar classified the engines as 2009 model year engines because it began assembling them in 2009. Navistar has stated they dispute the allegations and would “aggressively defend” their position.

On July 20, 2015, Navistar announced that it was refinancing the $697.5 million senior secured term loan facility of Navistar, Inc., which matures in August 2017, with a new $1.040 billion senior secured term loan, which will mature in August 2020. The refinancing will extend the maturity of the term loan facility and provide additional liquidity and financial flexibility for the company.

Brands

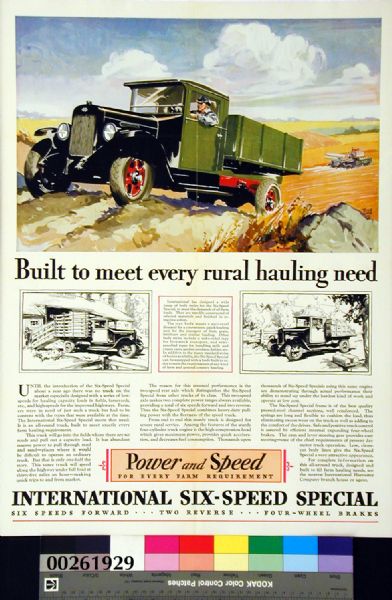

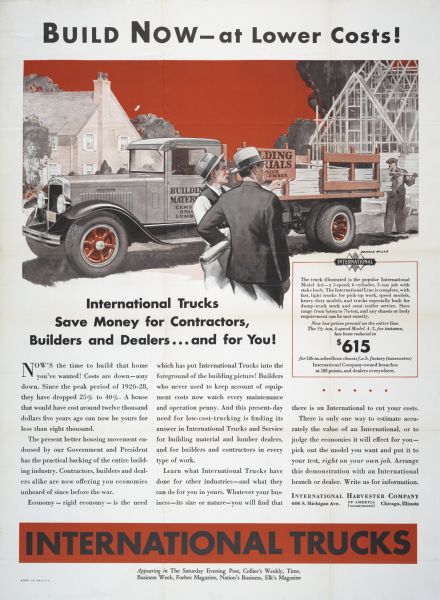

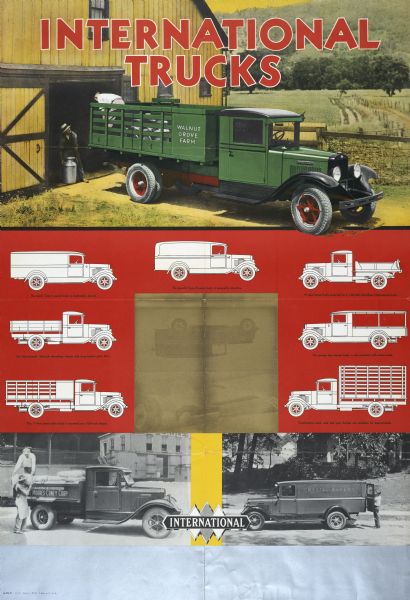

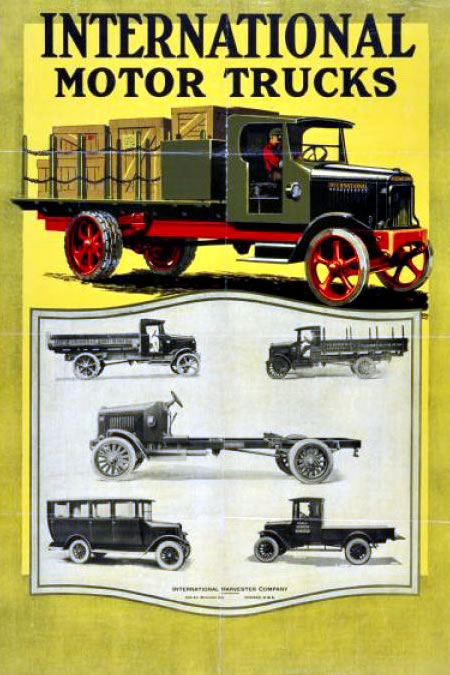

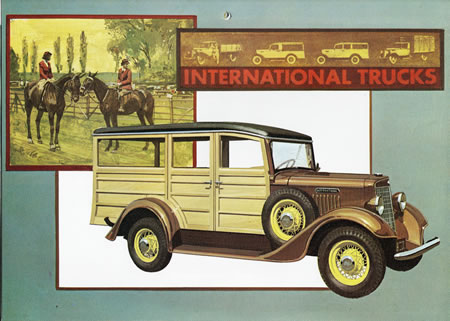

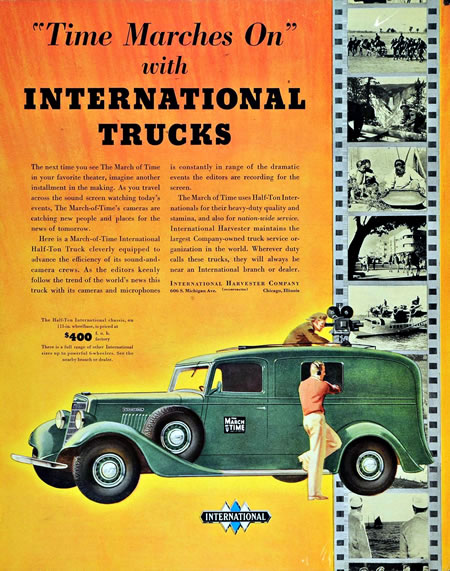

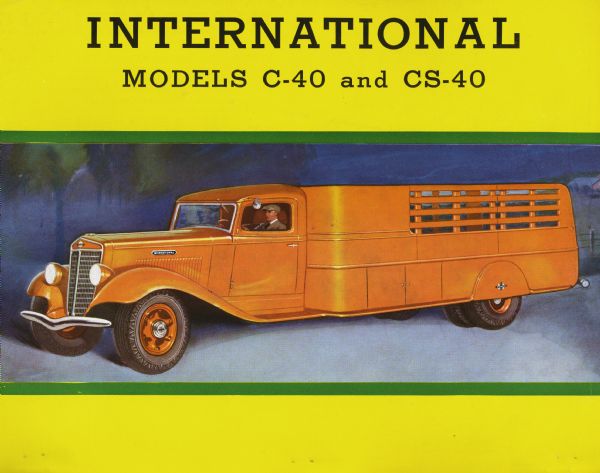

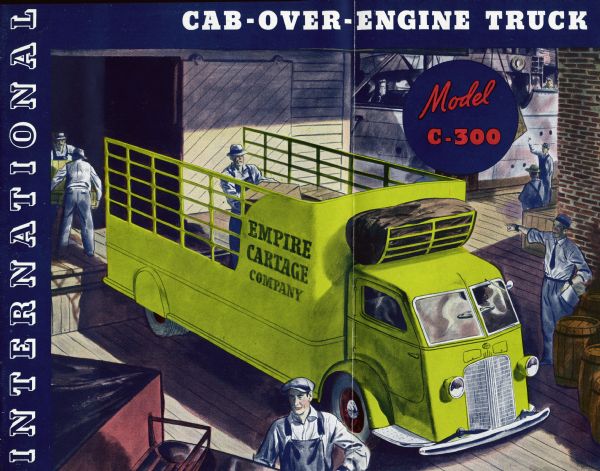

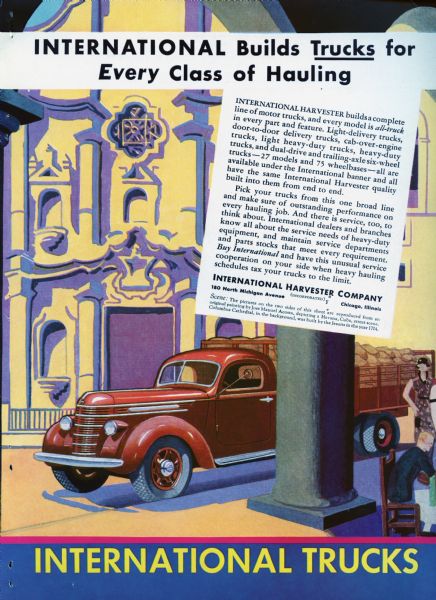

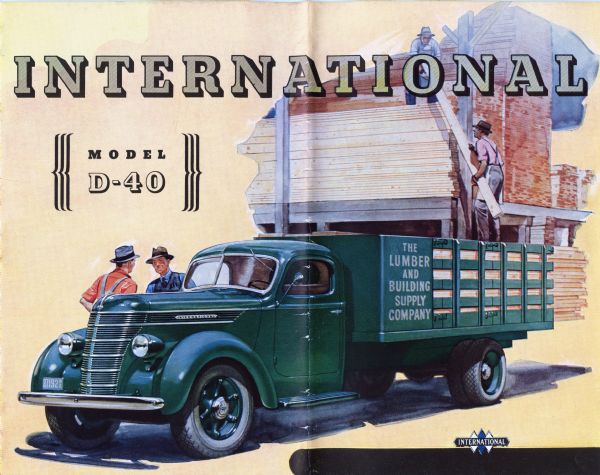

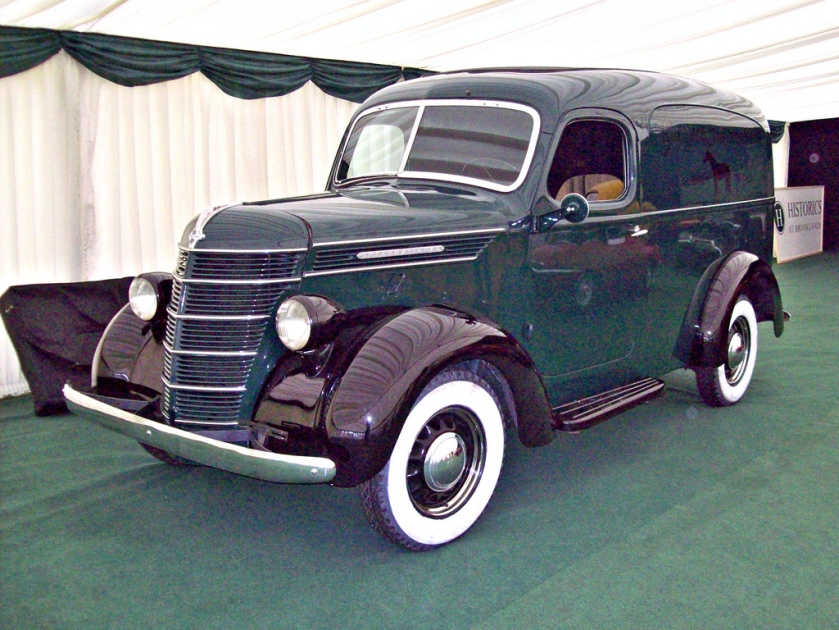

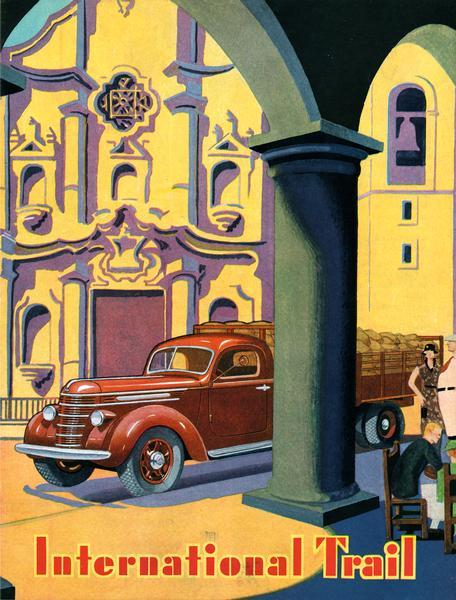

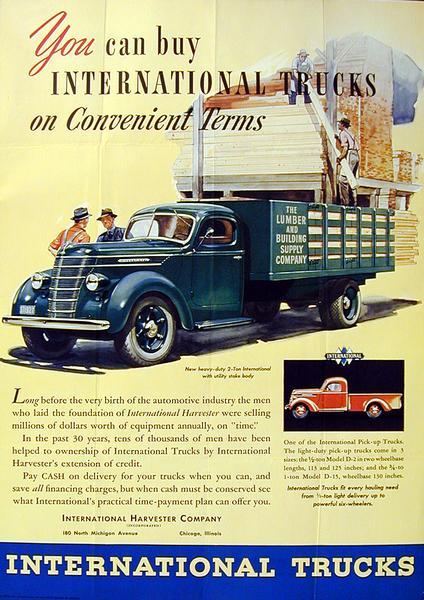

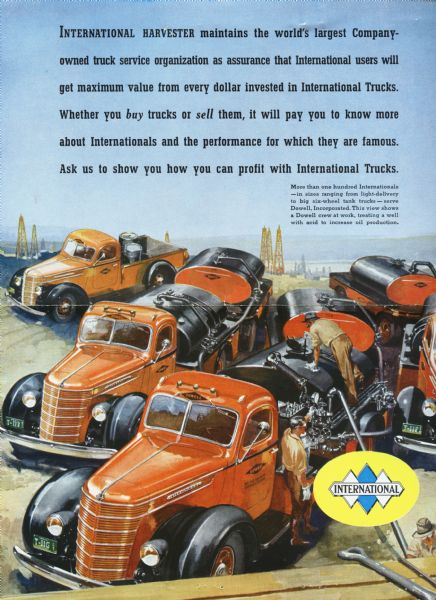

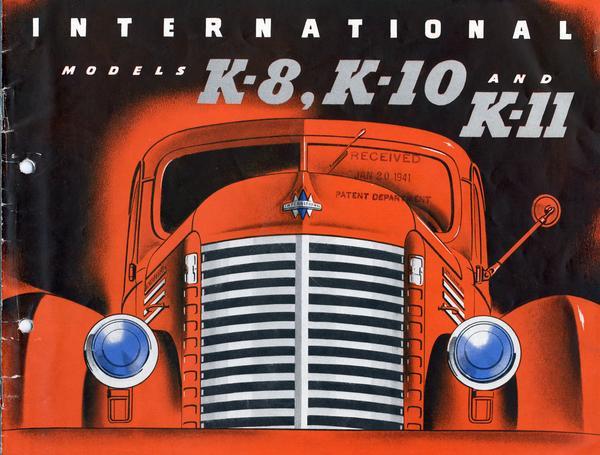

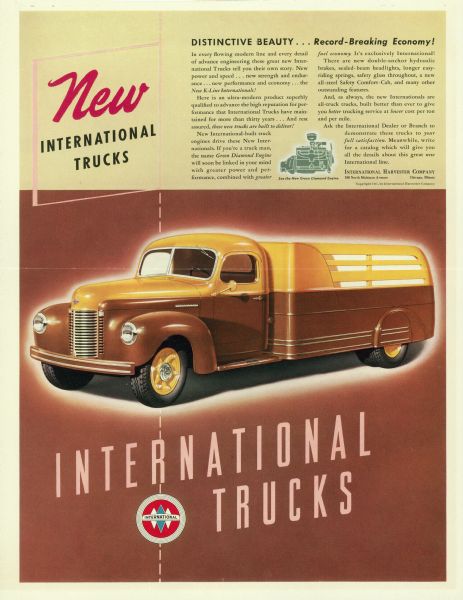

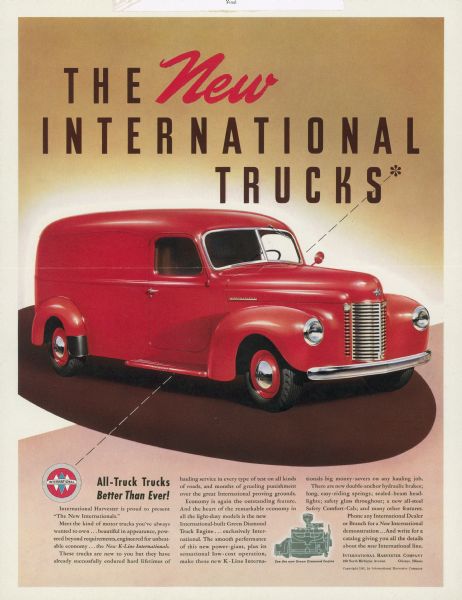

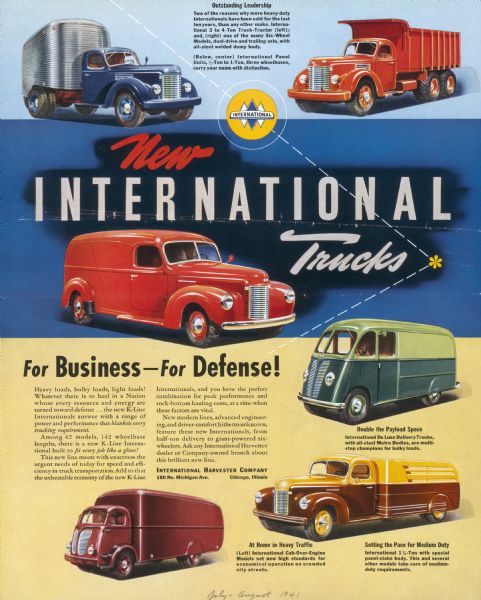

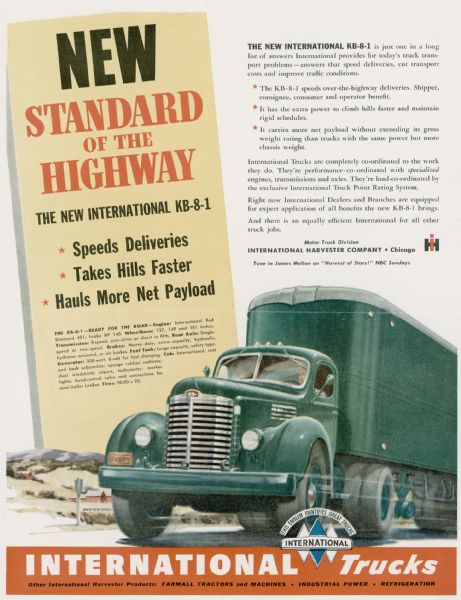

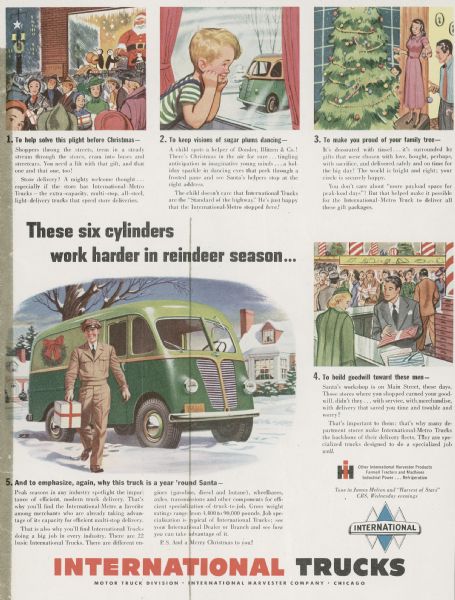

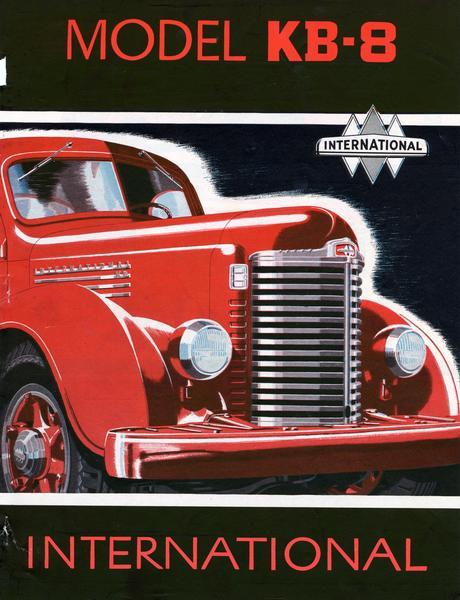

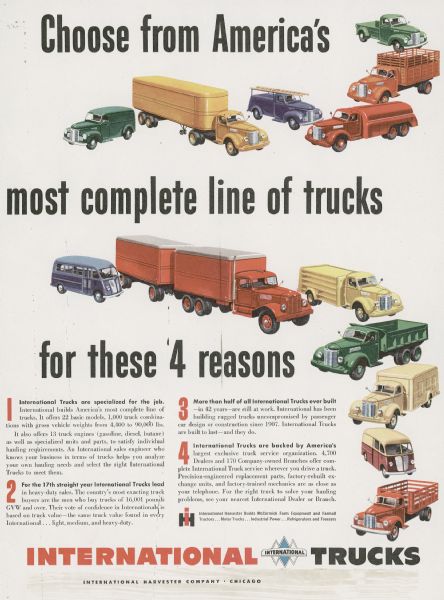

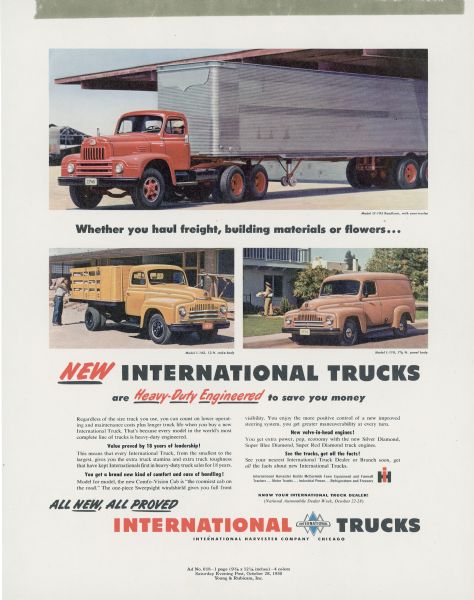

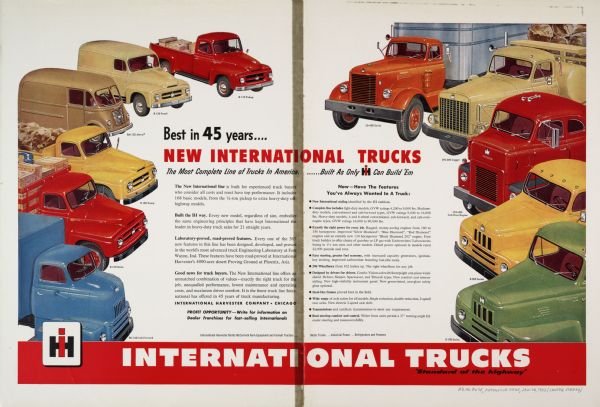

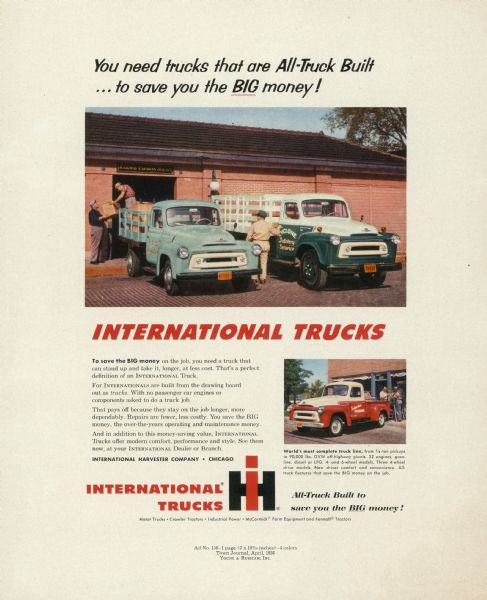

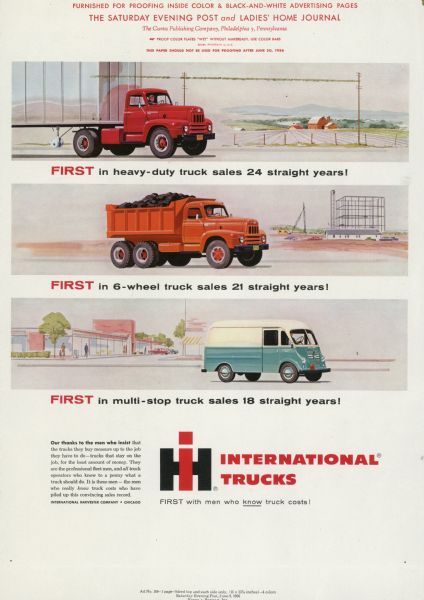

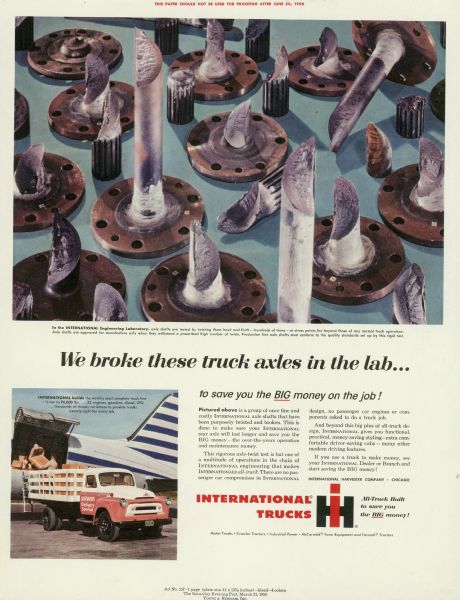

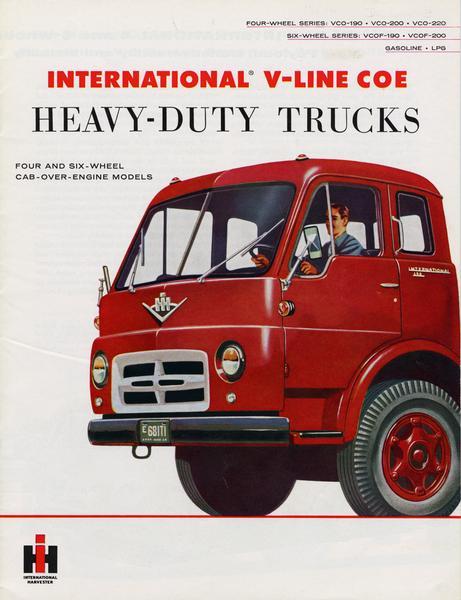

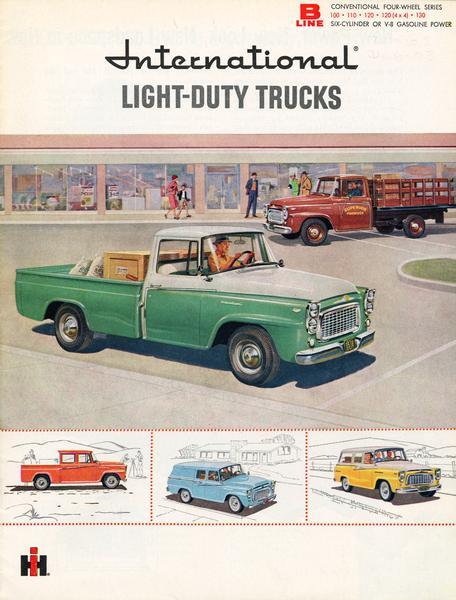

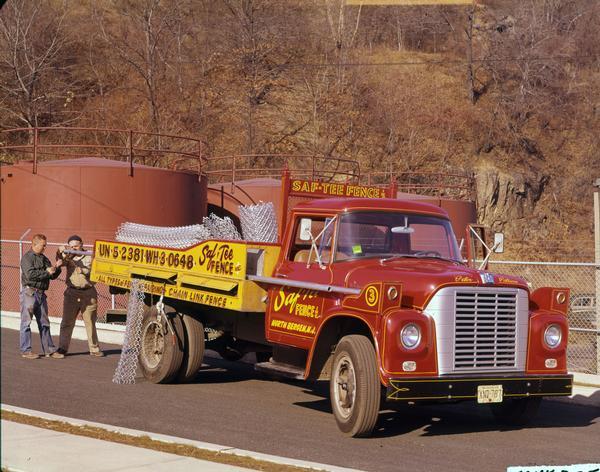

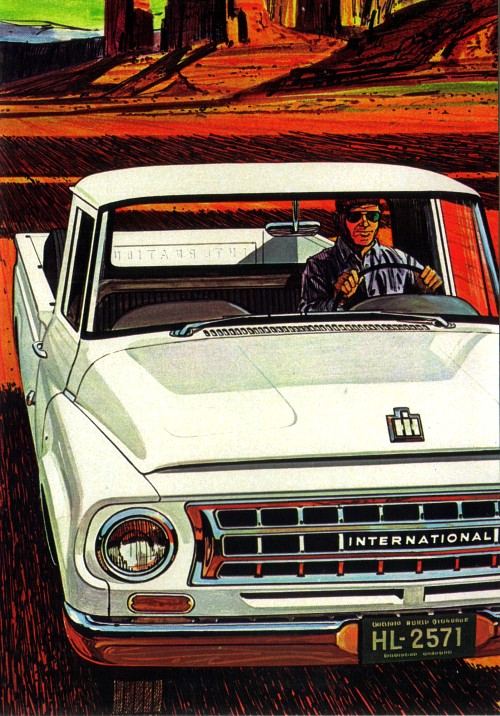

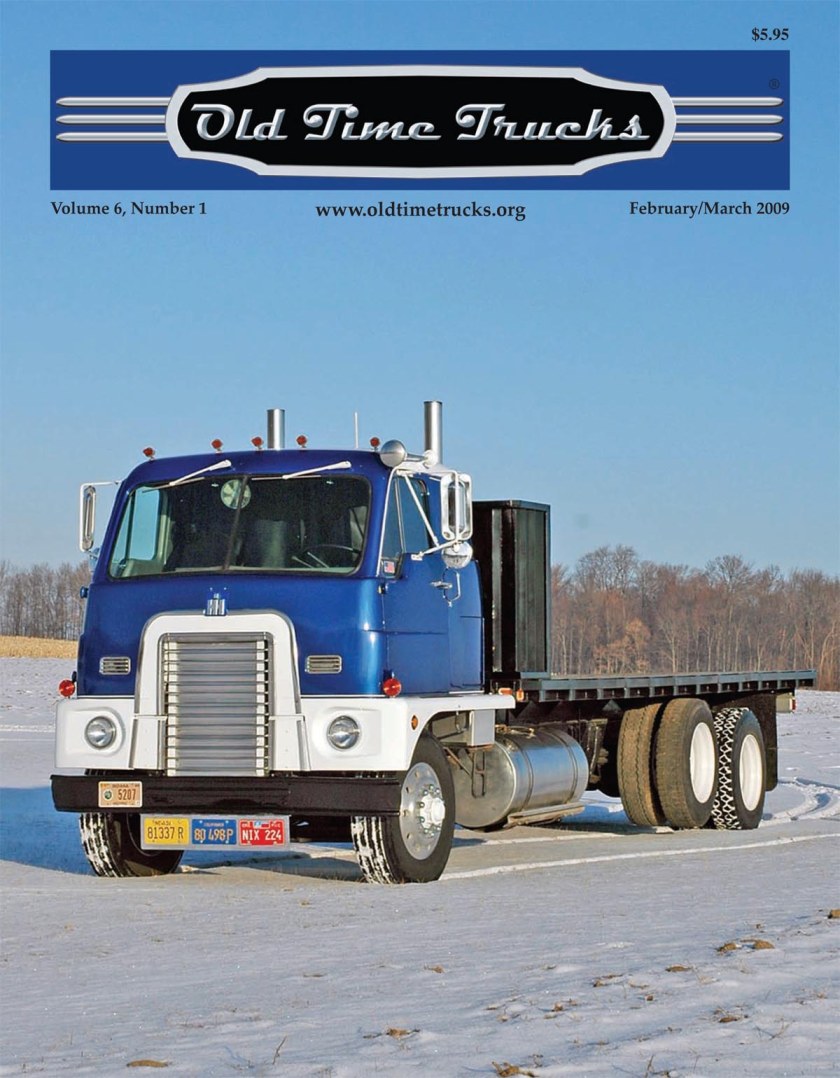

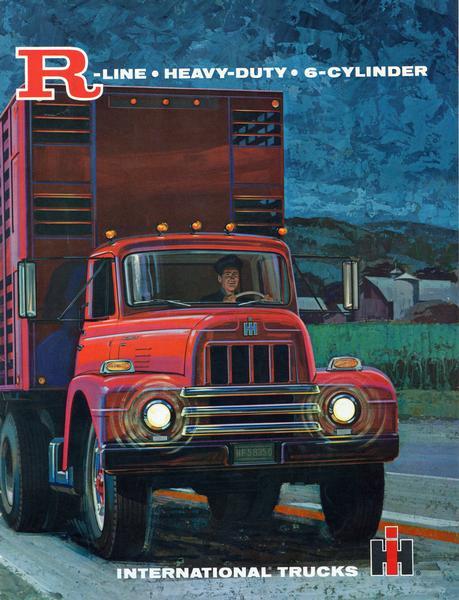

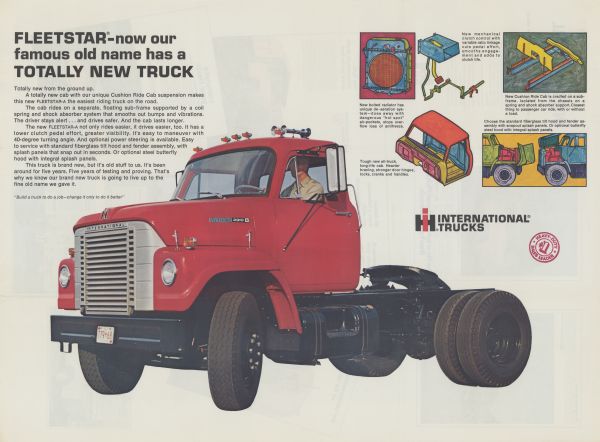

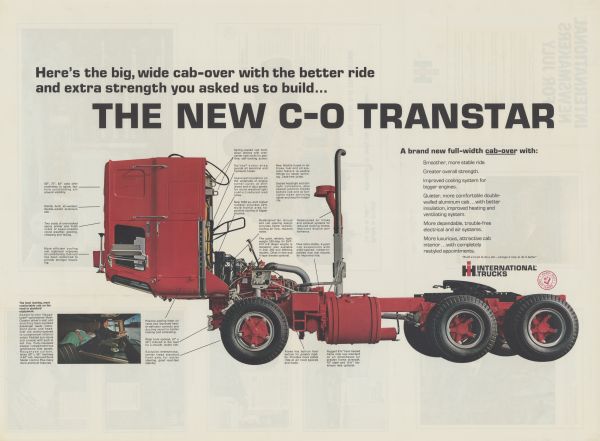

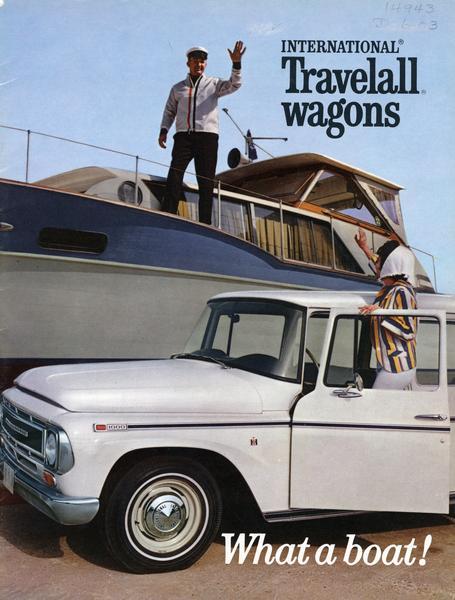

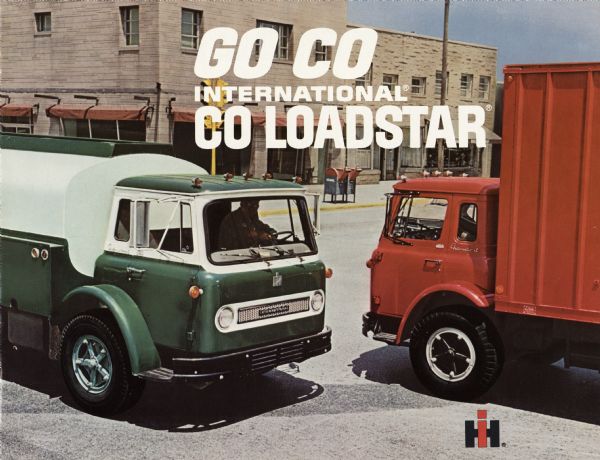

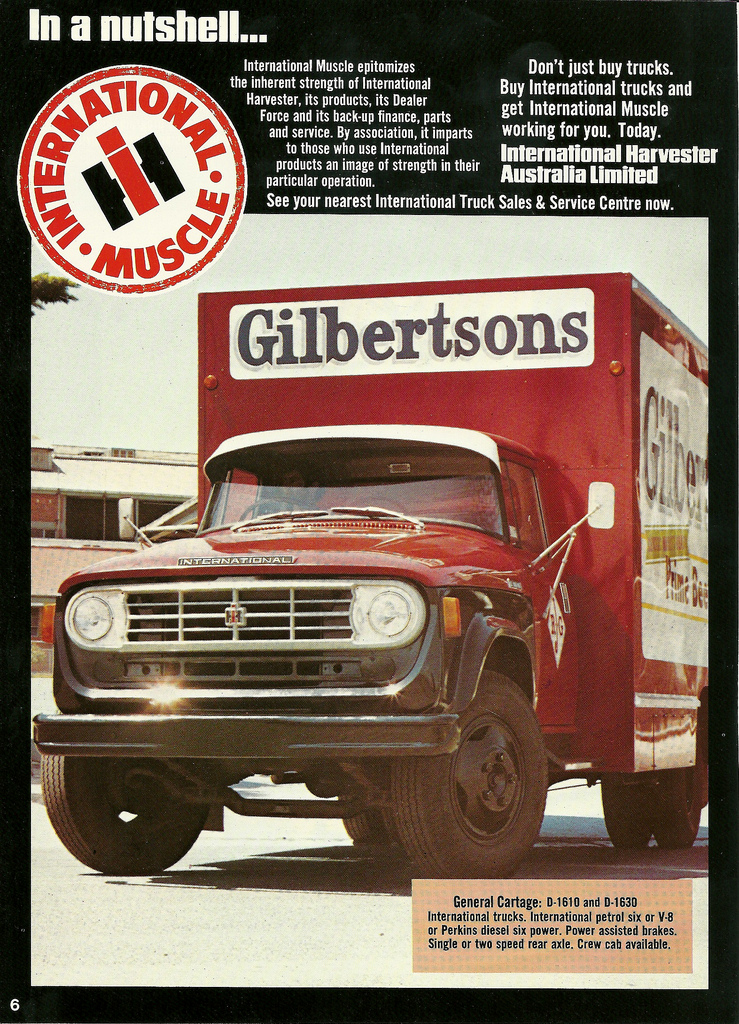

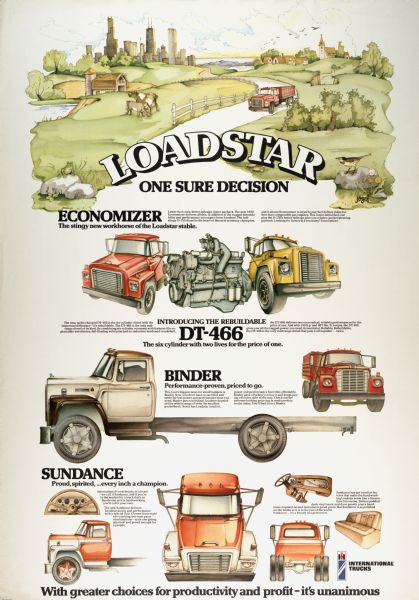

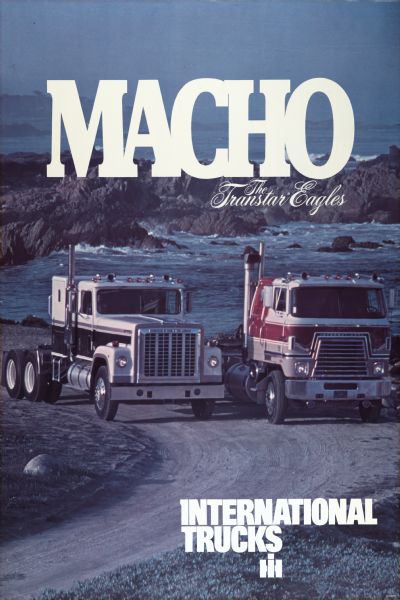

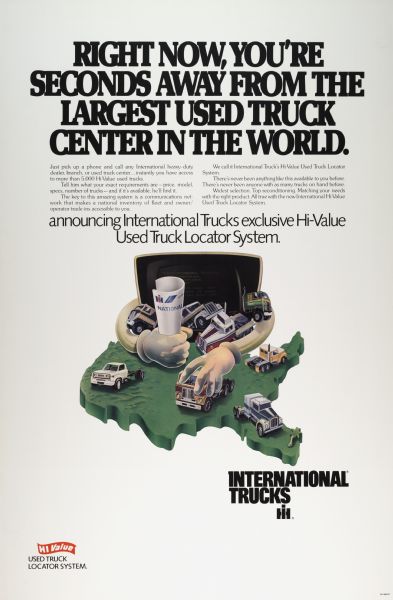

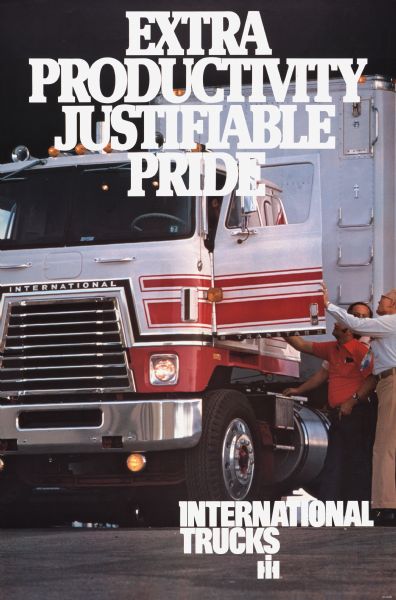

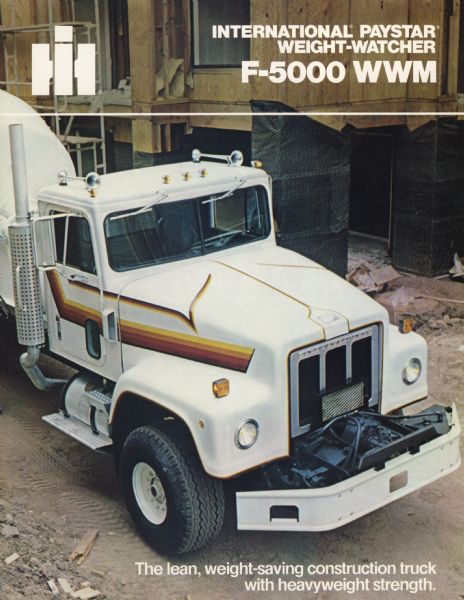

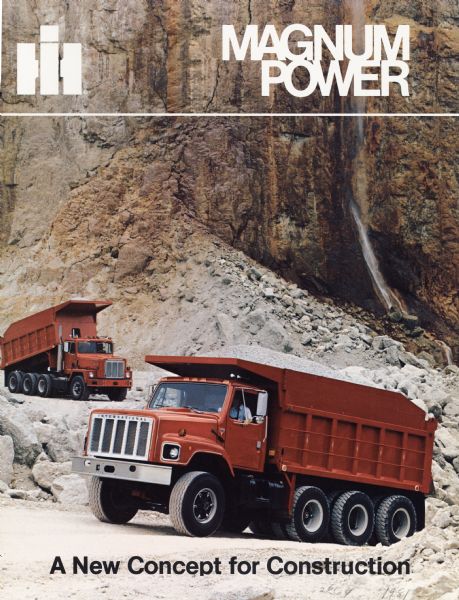

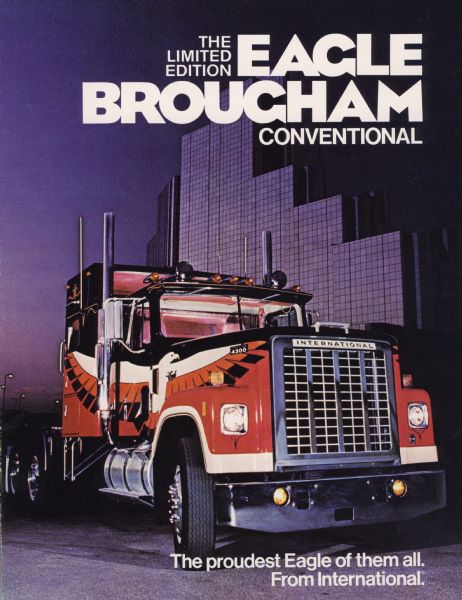

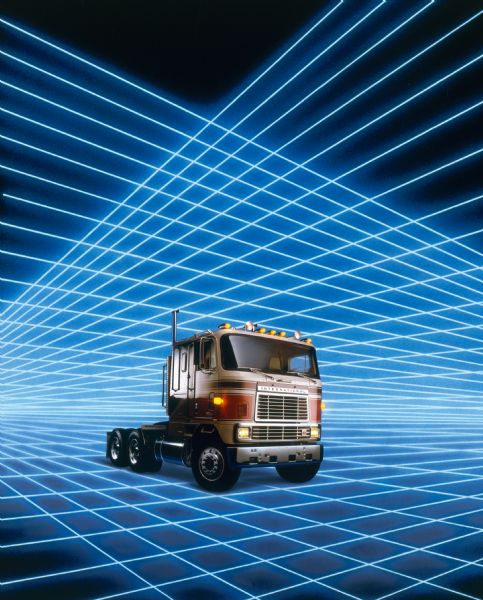

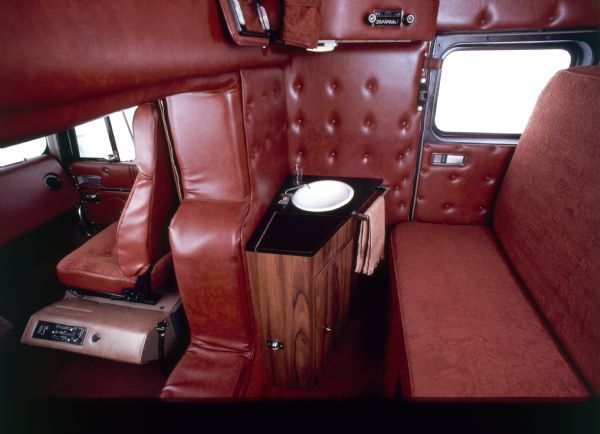

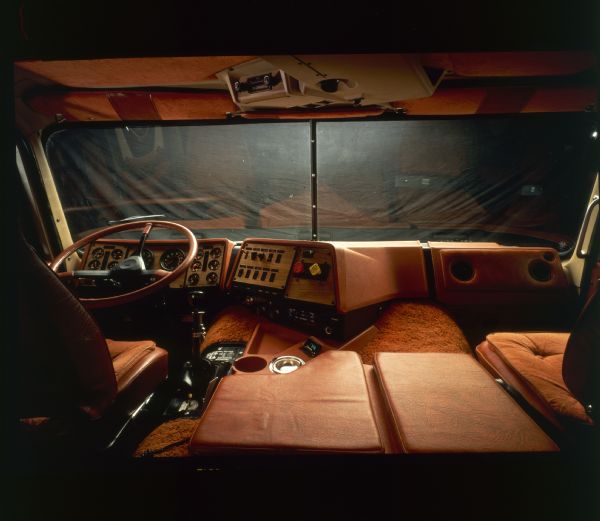

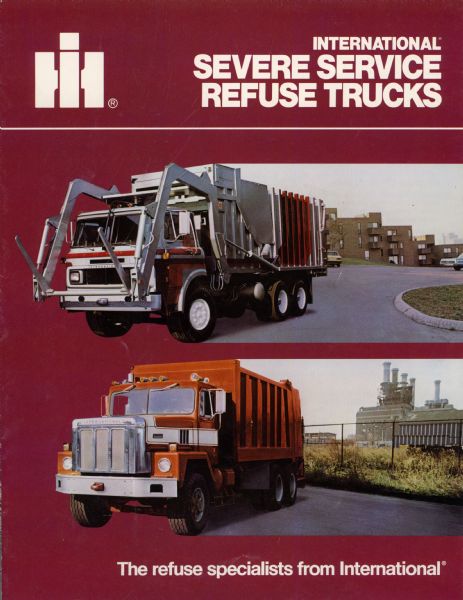

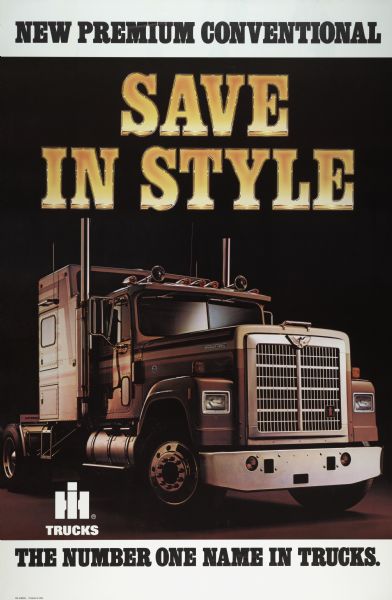

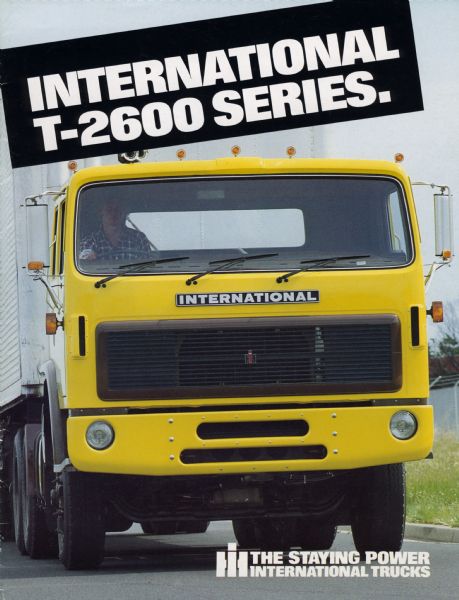

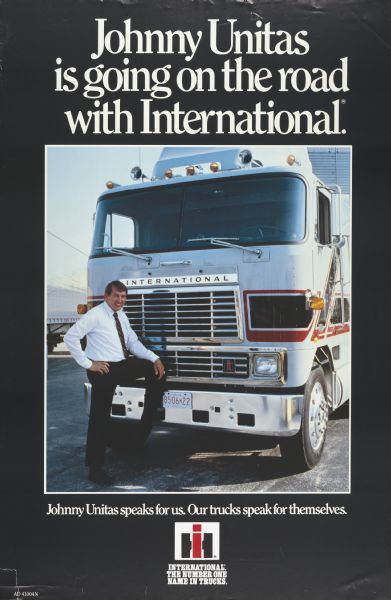

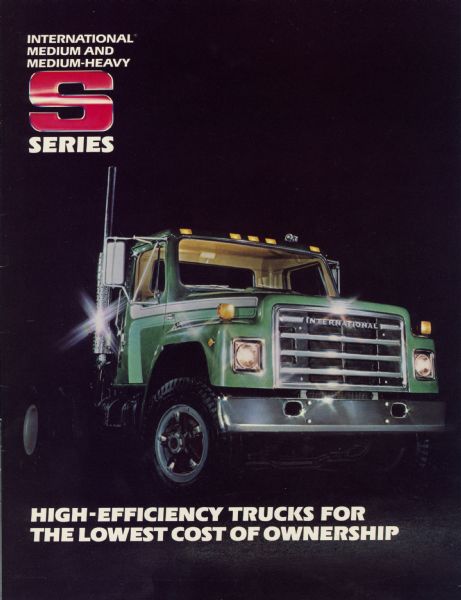

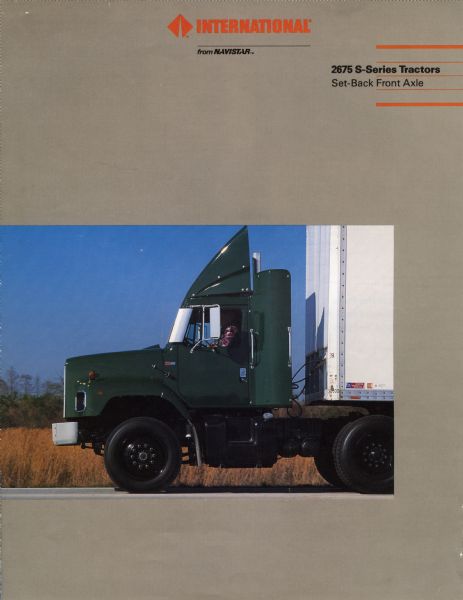

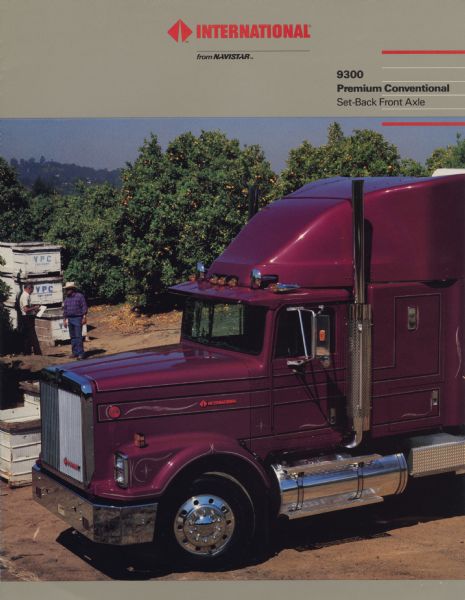

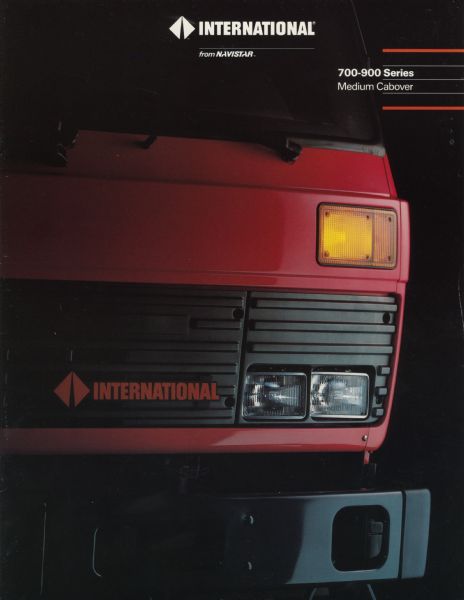

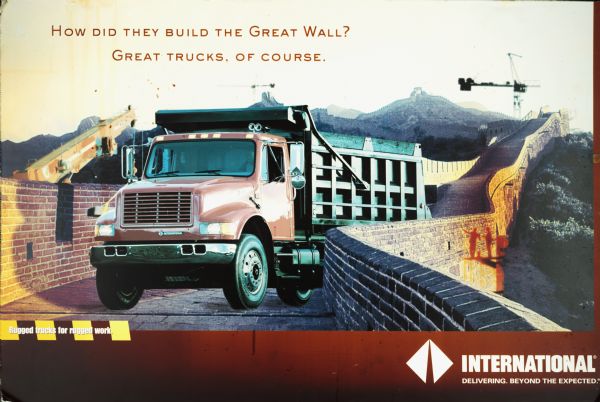

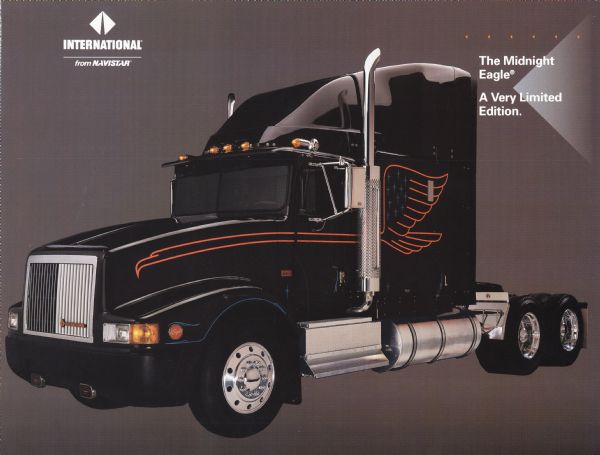

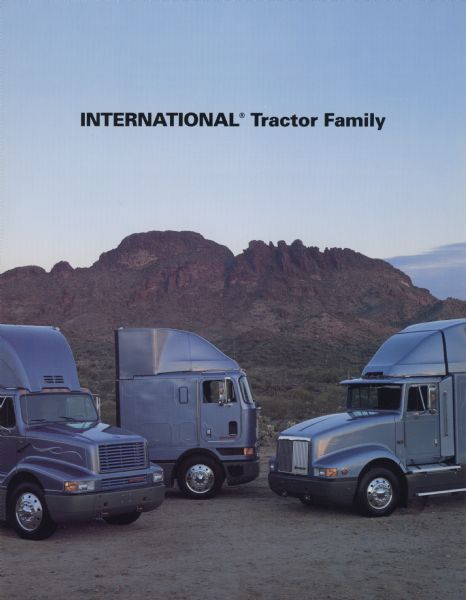

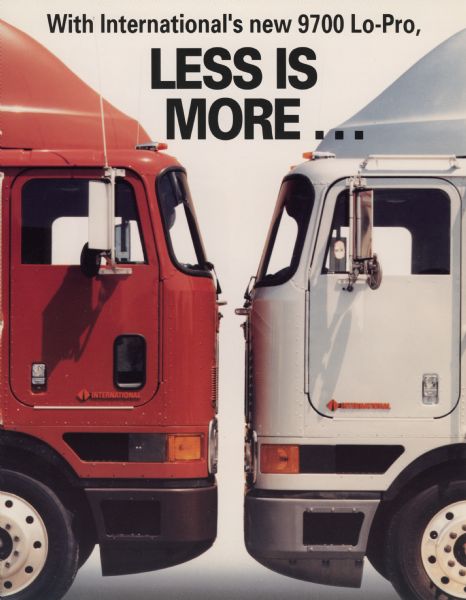

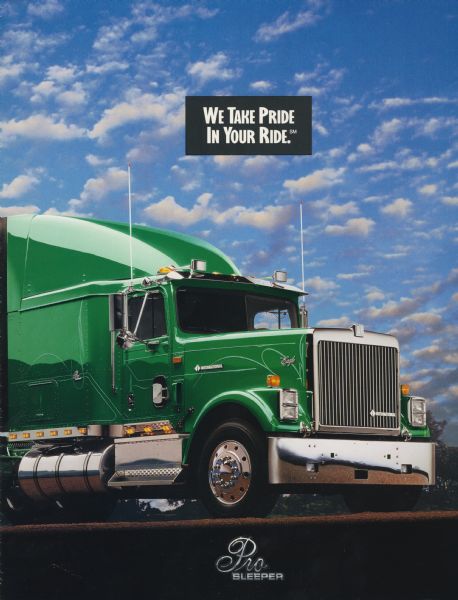

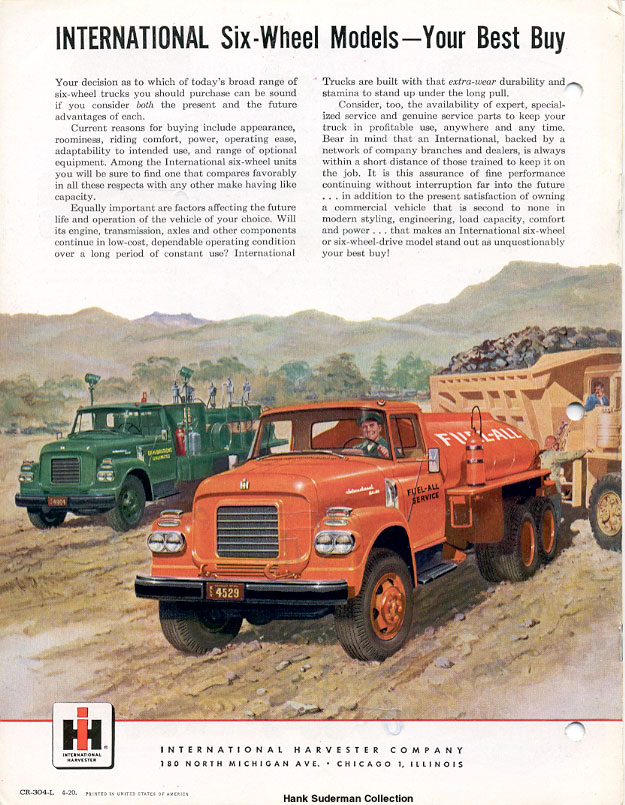

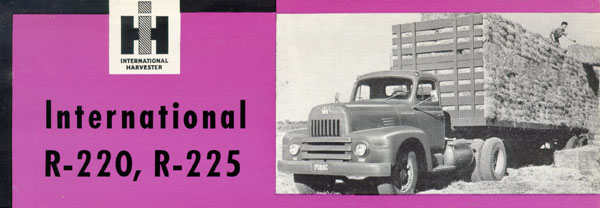

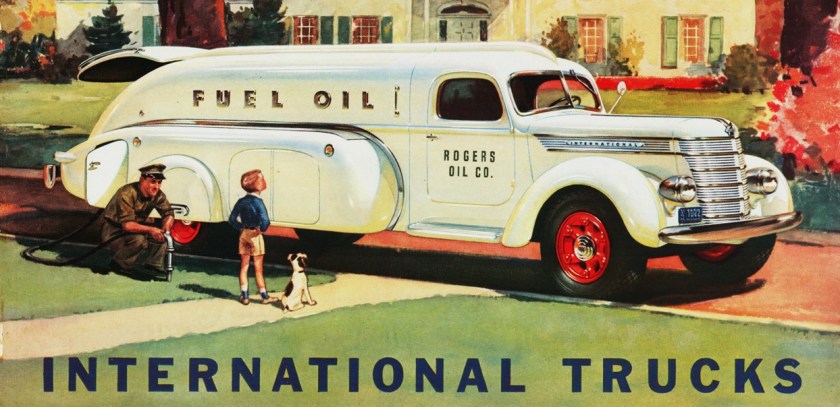

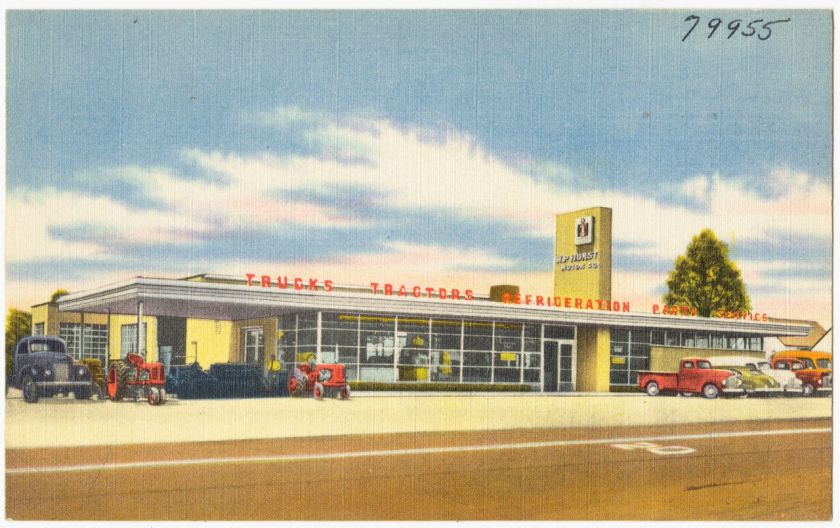

International Trucks

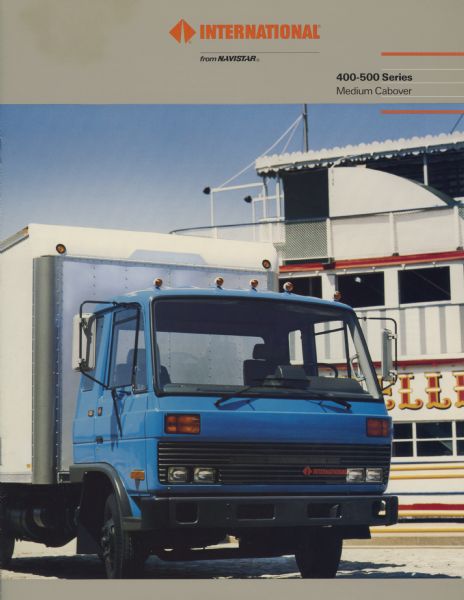

In 1986, after the transition from International Harvester to Navistar, the truck product line (essentially all that was left) dropped the “Harvester” portion of the brand name. International produces a variety of medium-duty, over-the-road, and severe-service trucks.

- Medium Duty

International TerraStar Class 4-5 conventional

International TerraStar Class 4-5 conventional International CityStar LCF (low-cab forward) cab-over

International CityStar LCF (low-cab forward) cab-over International DuraStar Class 6-7 conventional

International DuraStar Class 6-7 conventional

- Class 8

International LoneStar conventional

International LoneStar conventional International ProStar+ conventional

International ProStar+ conventional International 9000 Series conventional

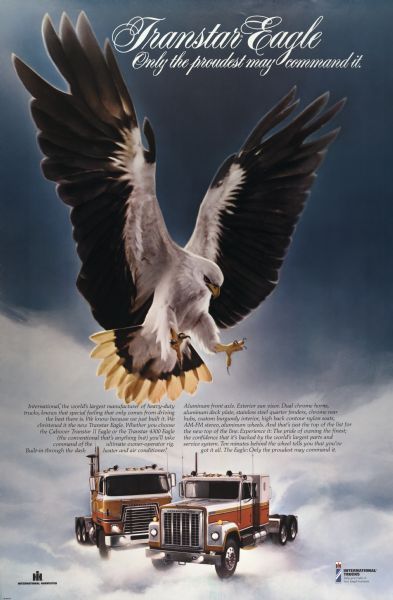

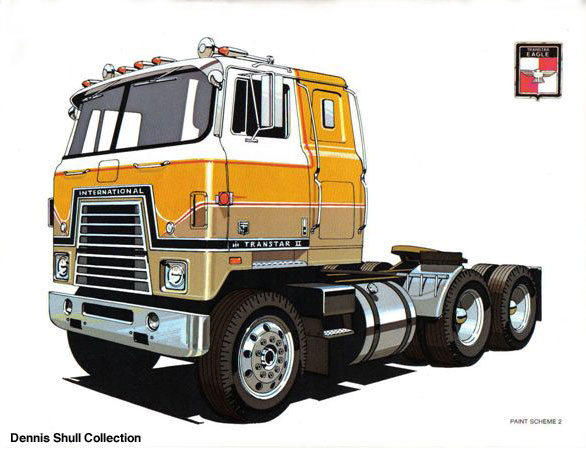

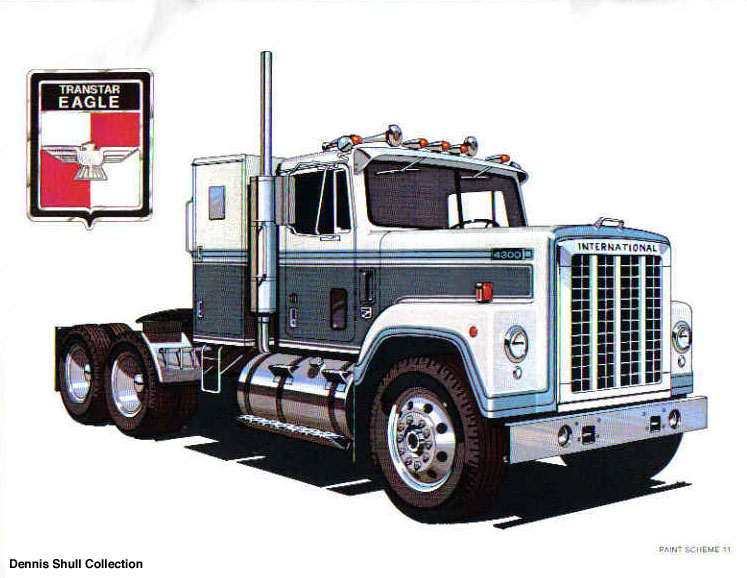

International 9000 Series conventional International TranStar conventional

International TranStar conventional

- Pickup trucks

- International SOTV-A

- International SOTV-B

- International MXT-MV

- International MXT-MVU

- International MaxxPro

- Class 8

- International ATX -6

- International ATX -8

- International 5000-MV

- International 7000-MV

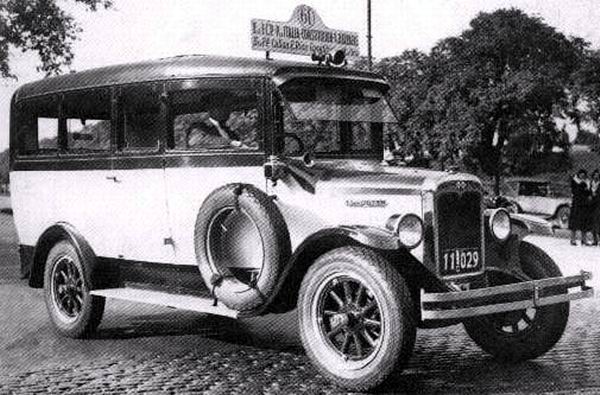

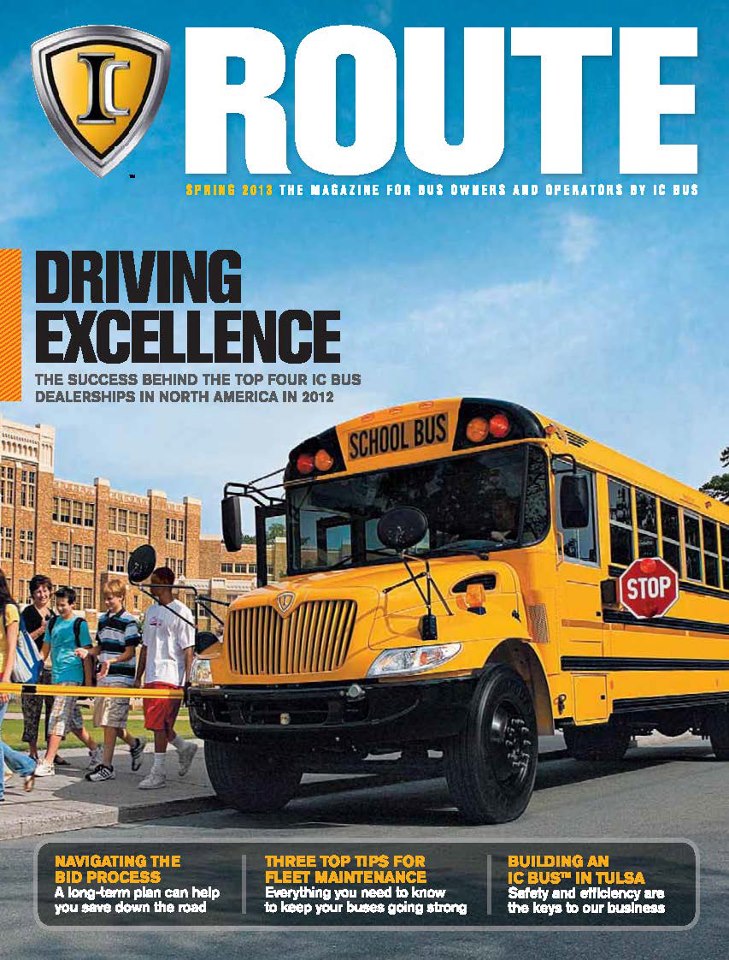

IC Bus

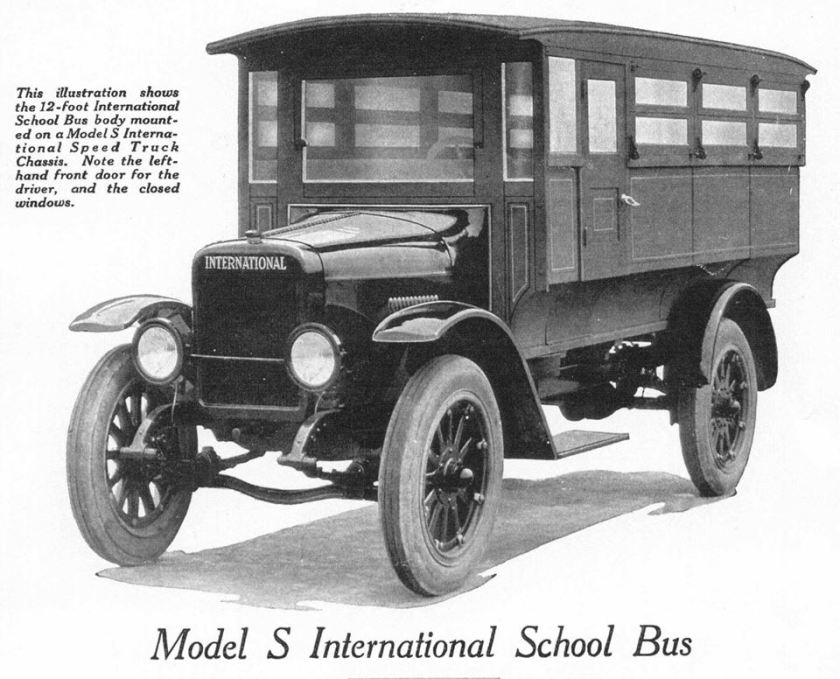

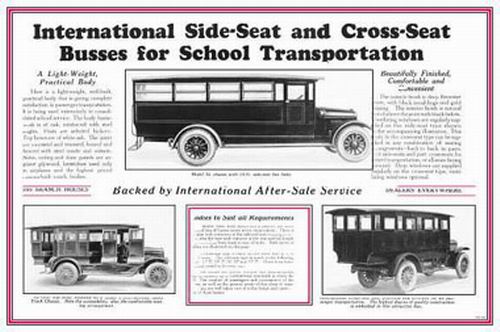

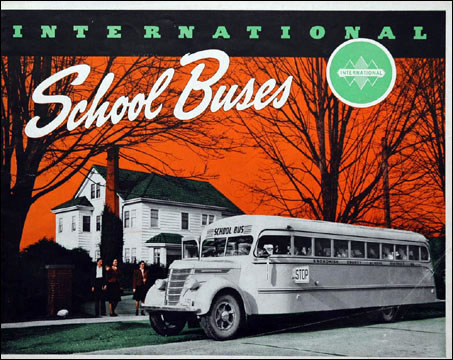

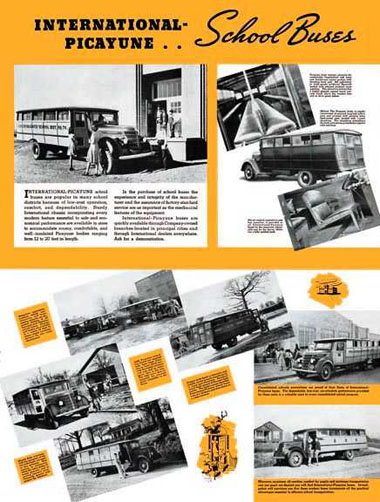

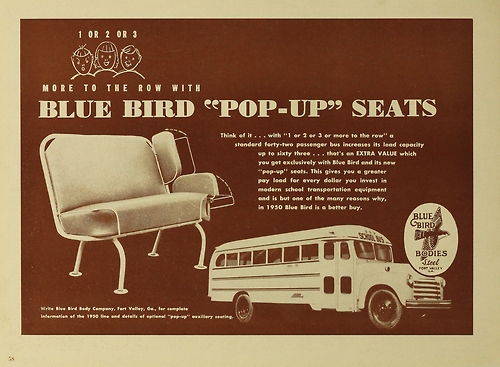

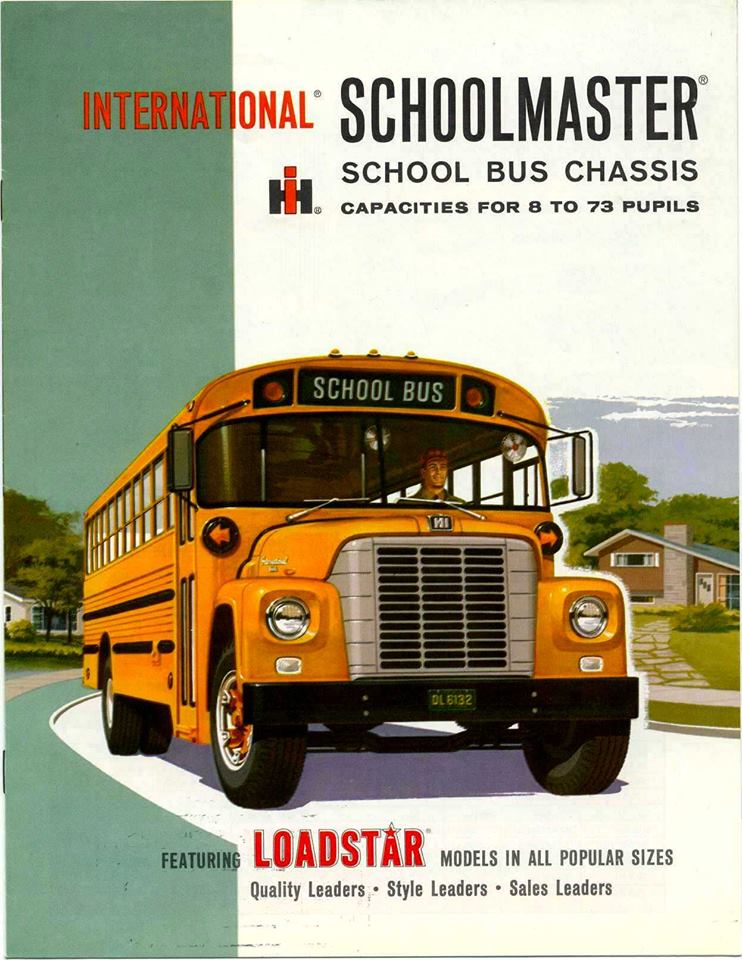

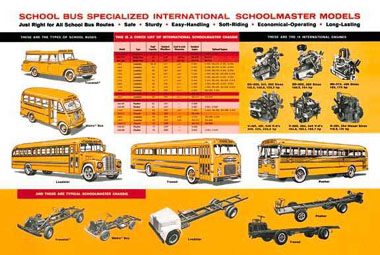

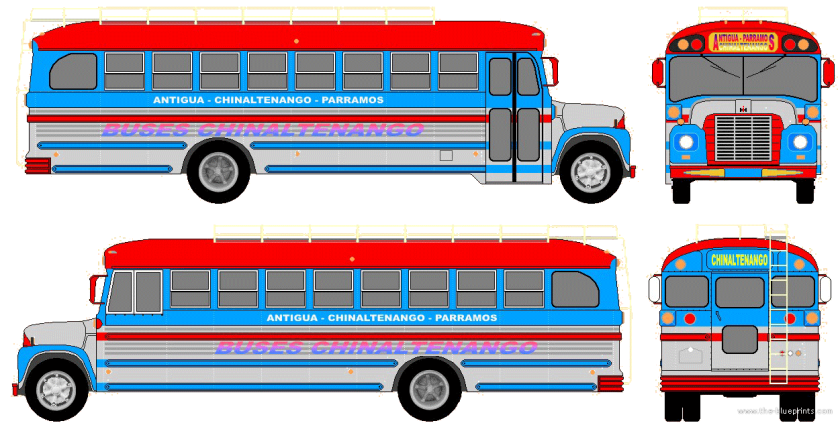

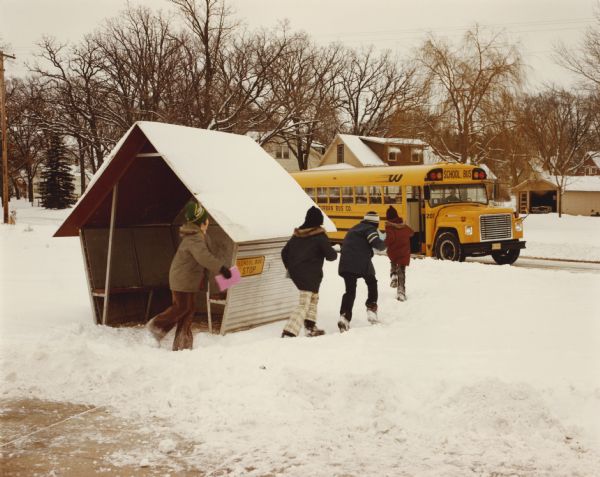

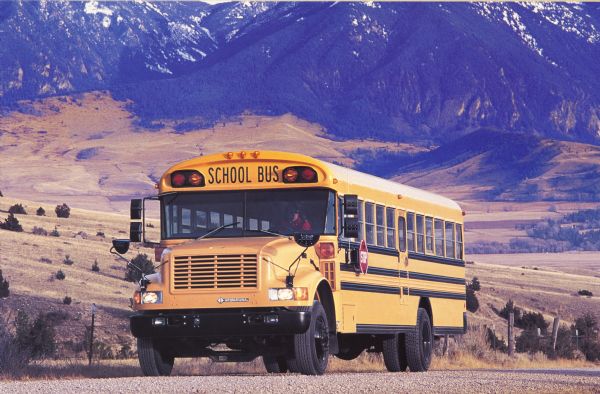

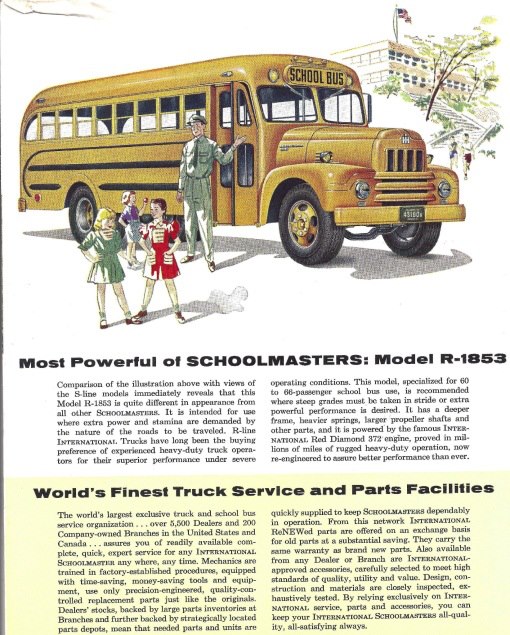

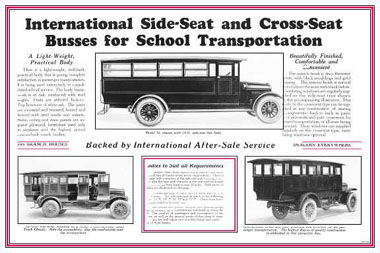

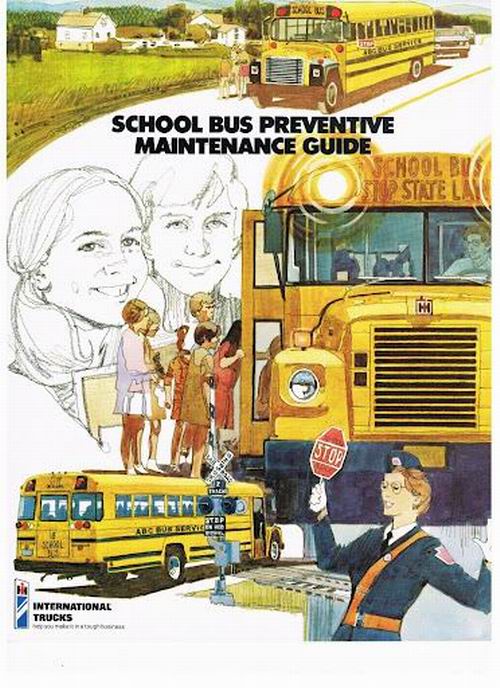

International has a long history in the school bus industry as a chassis provider, dating to when school buses first became motorized. In 1991, Navistar entered the school bus industry as a body manufacturer when it began its acquisition of AmTran, an Arkansas-based company founded as Ward Body Works in 1933. Today, IC Bus produces several models of full-sized school buses along with buses for commercial use.

- School/activity buses

AE-Series cutaway-cab conventional (based on International TerraStar)

AE-Series cutaway-cab conventional (based on International TerraStar)- BE-Series conventional (International 3300LP chassis)

CE-Series conventional (International 3300 chassis)

CE-Series conventional (International 3300 chassis)- available in diesel-electric hybrid configuration

RE-Series rear-engine transit-style (International 3000 chassis)

RE-Series rear-engine transit-style (International 3000 chassis)

- Commercial buses

Along with commercial-use derivatives of the school bus product lines, IC offers these distinct products:

- AC-Series cutaway cab (based on International TerraStar)

- HC-Series cutaway cab (based on International DuraStar)

- available in diesel-electric hybrid configuration

- LC-Series low-floor cutaway cab (based on International DuraStar LP)

- Motorcoaches

IC Bus has introduced concept vehicles in both 40 feet (12 m) and 45 feet (14 m) lengths.

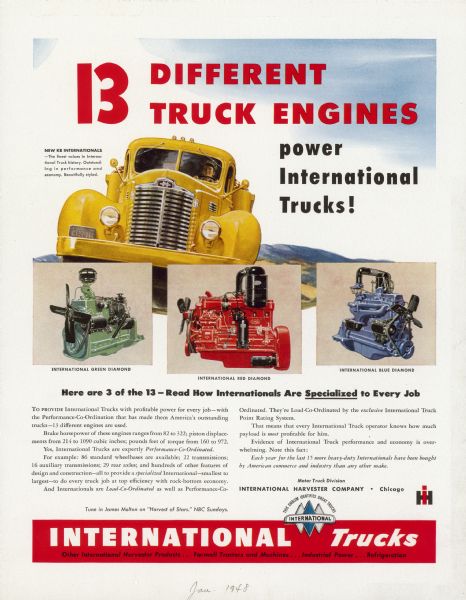

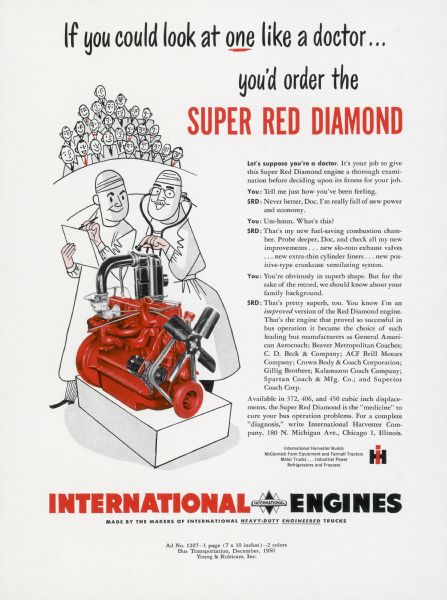

International Truck and Engine recently launched the “MaxxForce” brand name for its line of diesel engines. Engines were rebranded as “MaxxForce” followed by a number corresponding to the engine’s displacement, rounded up. So the 4.5L VT275 became the “MaxxForce 5. The Maxxforce Diesel engine line has recently been discontinued as a result of Navistar International having many issues and reports of problems with the engine. Ford continued to use the Power Stroke brand name on their International-sourced engines. However, the new 6.7L Power Stroke is not an International designed engine.

Joint ventures

Ford Motor Company

Since the 1980s, Navistar has had a close relationship with Ford Motor Company. The relationship started out as an engine-sharing deal, but evolved into the production of entire vehicles. However, in May 2014, Ford cut Navistar out of the business of the F-650 and F-750 commercial trucks. Navistar had built them for Ford since 2001. Beginning in 2015, Ford plans to start making the trucks themselves. It is approximately a $400 million a year business.

Ford PowerStroke diesel

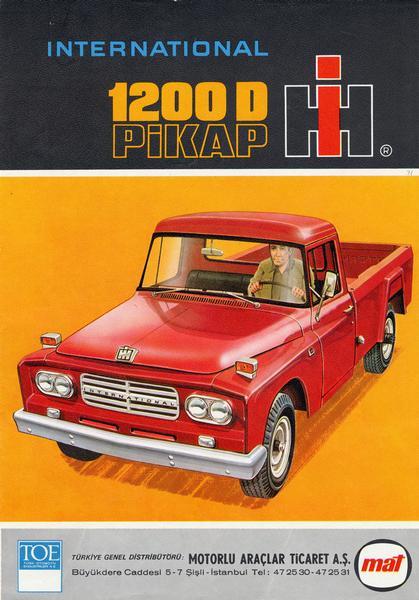

As a result of the gas crises of the 1970s, big-block gasoline V8 engines (such as the Ford 460) had begun to fall out of favor with pickup-truck buyers. In the 1980s, diesel engines in American pickup trucks (introduced by General Motors in 1978) had become popular, as they offered the power of a big-block V8 with the fuel economy of a smaller engine. Ford entered into a supply agreement with International Harvester to receive its 6.9 L IDI V8 engine. The first diesel-powered Ford pickup trucks debuted for 1982; it was available for 3/4 and 1-ton models. GM at the time had a Detroit Diesel V8 engine also on its debut, prior to that GM used a 350 Diesel. Dodge started using a Cummins six-cylinder in 1988.

In 1994, when the International 7.3 L IDI V8 was replaced by the T444E, the diesel option was branded “Ford PowerStroke” to emphasize the switch to direct injection. Throughout the 1990s and 2000s, Ford offered International/Navistar V8 (as the DT inline-6 was far too large to package in a pickup truck) in the Ford Super Duty pickup trucks.

Ford Super Duty pickup trucks.

2004-15 F-750 Super Duty in use servicing a water pump

As of 2010, the 6.4 L Ford PowerStroke V8 was the last of the International/Navistar diesels used in Ford’s F-Series Super Duty lineup. When Ford redesigned the Super Duty in 2011, it was fitted with a 6.7 L V8 designed and produced by Ford.

Blue Diamond Truck

In 2001, Navistar formed a joint venture with longtime (20 years) customer Ford Motor Company to manufacture medium-duty trucks and parts, including diesel engines for both parent companies. The new company, Blue Diamond Truck Co. LLC, operates in the Navistar plant in General Escobedo, Mexico. Its first products were the

2004 Ford F-650 and F-750 medium-duty trucks.

On 16 September 2010, Anhui Jianghuai Automobile Co., Ltd. (JAC) announced joint ventures with NC2 Global and Navistar International Corporation that will develop, build, and market heavy duty trucks and diesel engines in China.

Navistar formed a joint venture with Mahindra & Mahindra to build heavy trucks in India under the “Mahindra International” brand, which has since been renamed Mahindra Navistar. These trucks were displayed at Auto Expo 2010 in Delhi, India.

The Joint Venture ceased as Navistar exited the joint venture in 2013.

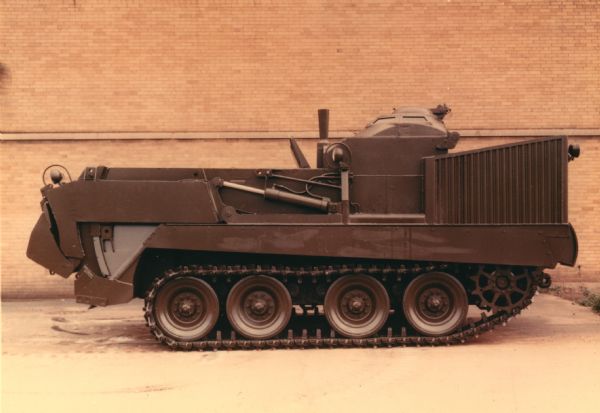

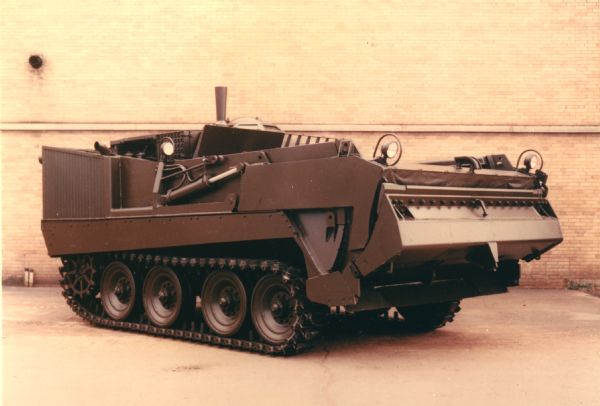

Tatra

Tatra and Navistar Defence introduced at Eurosatory Exposition in Paris, France (June 14–18, 2010) the results of their strategic alliance since October 2009, the models ATX6 (universal container carrier) and ATX8 (troop carrier) The vehicles appear to be based on Tatra T815-7 (T817) 6×6, 8×8 chassis, suspension and cabins while using Navistar engines and other components. Under the deal Navistar Defence and Tatra A.S. will market the vehicles in North America, which includes sales to the United States military and foreign military sales financed by the United States government. Tatra will source parts and components through Navistar’s global parts and support network for Tatra trucks delivered in markets outside of North America, as well as market Navistar-Tatra vehicles around the world in their primary markets.

Tatra T815-7 (T817) 6×6, 8×8 chassis, suspension and cabins while using Navistar engines and other components. Under the deal Navistar Defence and Tatra A.S. will market the vehicles in North America, which includes sales to the United States military and foreign military sales financed by the United States government. Tatra will source parts and components through Navistar’s global parts and support network for Tatra trucks delivered in markets outside of North America, as well as market Navistar-Tatra vehicles around the world in their primary markets.

Others

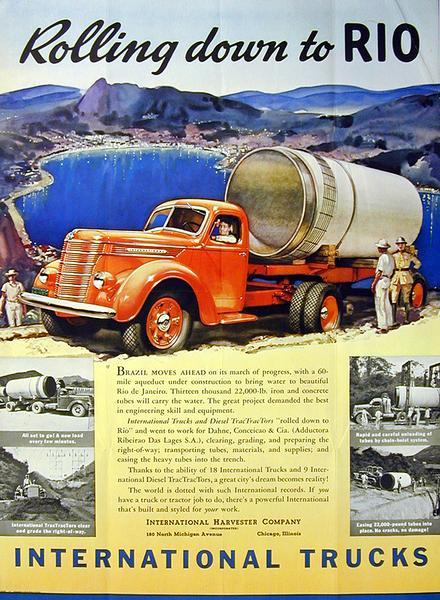

- In 2005, Navistar purchased MWM International Motores, a Brazilian engine manufacturer formerly associated with Deutz AG.

- Navistar International has a contract with Budget Truck Rental to produce their rental trucks.

- Navistar entered into an agreement to purchase General Motors’ medium duty truck unit in 2007, but because of changing market conditions, the purchase was not concluded.

Plug-in electric vehicles

Plug-in hybrid electric bus

The U.S. Department of the Energy announced the selection of Navistar Corporation for a cost-shared award of up to US$10 million to develop, test, and deploy plug-in hybrid electric vehicle(PHEV) school buses. The project aims to deploy 60 vehicles for a three-year period in school bus fleets across the nation. The vehicles will be capable of running in either electric-only or hybrid modes that can be recharged from standard electrical outlets. Because electricity will be their primary fuel, they will consume less petroleum than standard vehicles. To develop the PHEV school bus, Navistar will examine a range of hybrid architectures and evaluate advanced energy storage devices, with the goal of developing a vehicle with a 40-mile (64 km) range. Travel beyond the range will be facilitated by a clean diesel engine capable of running on renewable fuels. The DOE funding will cover up to half of the project’s cost and will be provided over three years, subject to annual appropriations.

eStar electric van

The eStar is an all-electric van manufactured in Wakarusa, Indiana. Production began in March 2010 and first deliveries began two months later. The technology used in eStar was licensed to Navistar in 2009 in a joint venture with Modec and Navistar bought the intellectual property rights from the Modec’s bankruptcy administrators in 2011. The introduction of the eStar was supported by a US$39.2 million U.S. Department of Energy stimulus grant under the 2009 American Recovery and Reinvestment Act.

The eStar has a 5,100 lb (2,300 kg) payload capacity and is available with a 14- or 16-foot cargo box. The vehicle is powered by a 70 kW 102 hp electric motor powered by an 80kWhr lithium-ion battery pack supplied by A123 Systems, and also uses regenerative braking. The electric van has a range of 100 mi (160 km), and a full charge takes between 6 and 8 hours. By May 2010 the eStar had received U.S. Environmental Protection Agency (EPA) and CARB certifications. The eStar also meets all Federal Motor Vehicle Safety Standards (FMVSS).

The first vans were delivered in May 2010 to FedEx Express for use in Los Angeles. Other customers include Pacific Gas and Electric Company (PG&E), The Coca-Cola Company, and Canada Post. The eStar has a price of US$150,000.

Criticism

In December 2011, the nonpartisan organization Public Campaign criticized Navistar International for spending $6.31 million on lobbyingand not paying any taxes during 2008-2010, instead getting $18 million in tax rebates, despite making a profit of $896 million and increasing executive pay by 81%. On Jan 31, 2005, Navistar Financial said it would restate financial statements for fiscal years 2002 and 2003 and the first three quarters of fiscal 2004, because it did not take into consideration potential changes to future income. On April 7, 2006, Navistar restated financial results from 2002 through 2004, and for the first three quarters of 2005, due to accounting practices that are the subject of a continuing review.

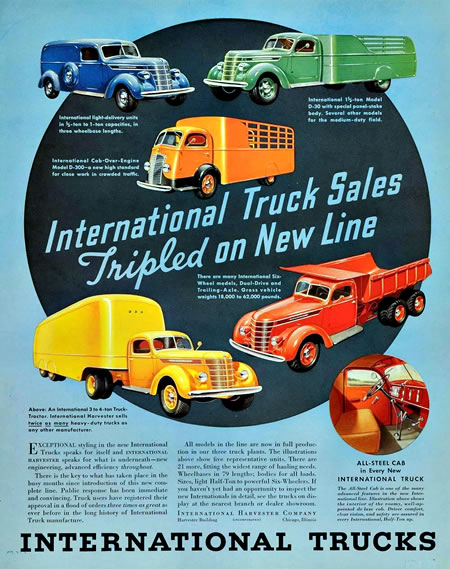

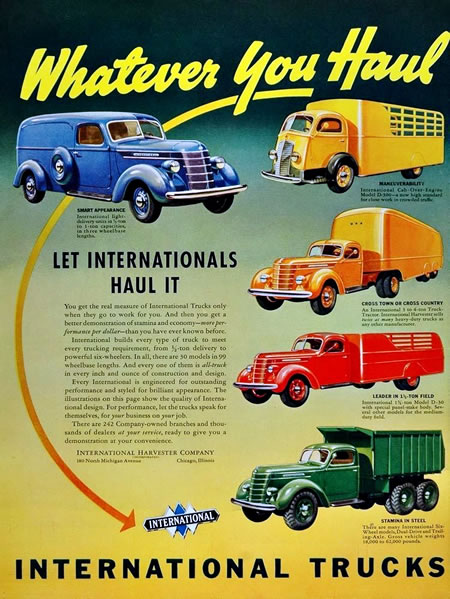

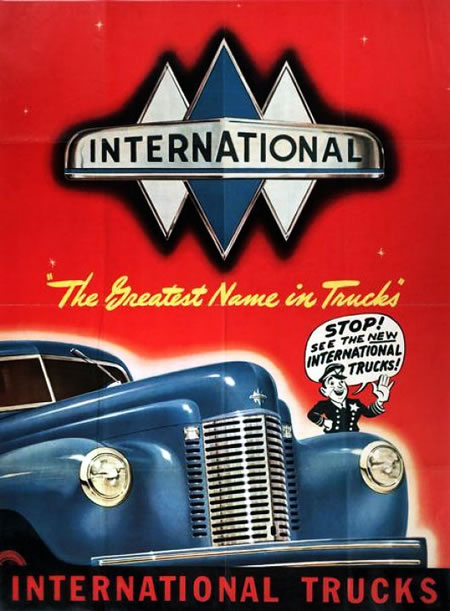

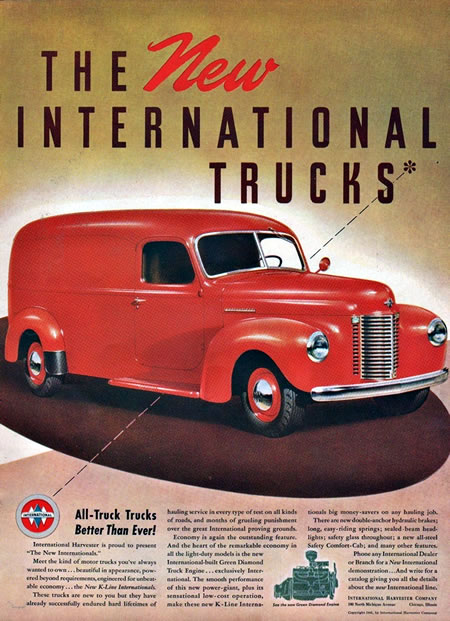

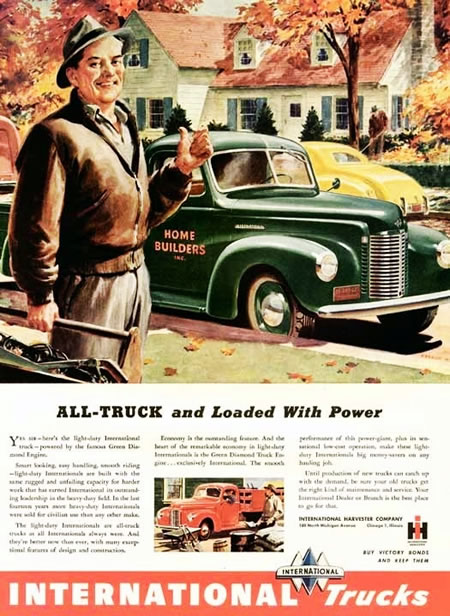

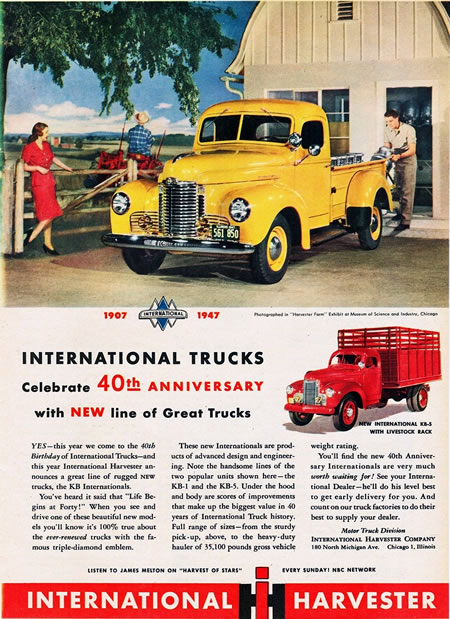

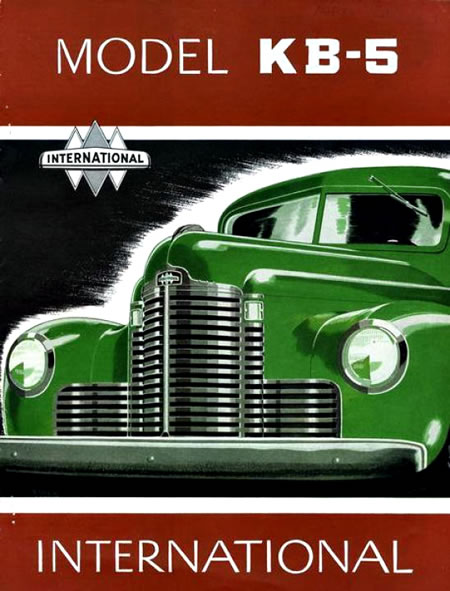

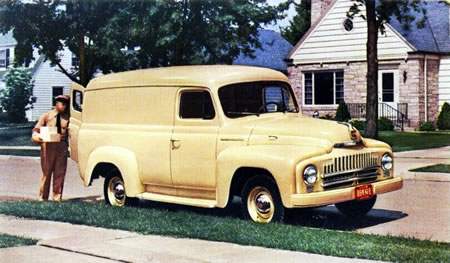

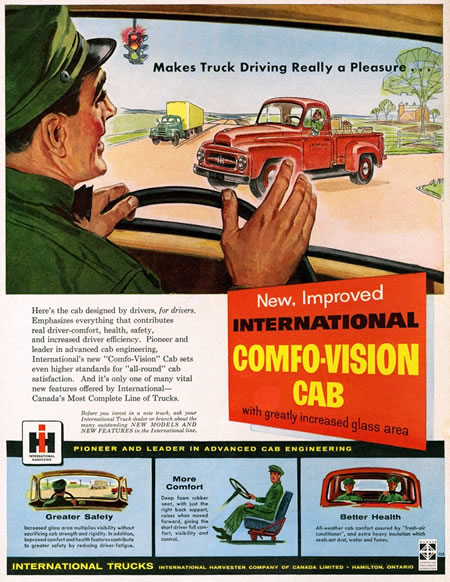

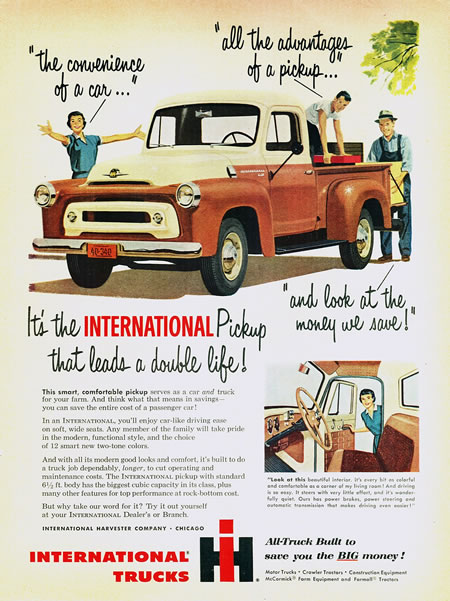

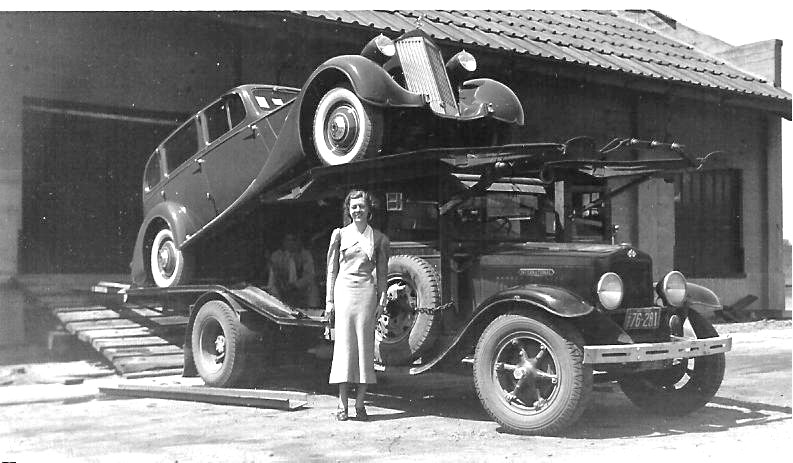

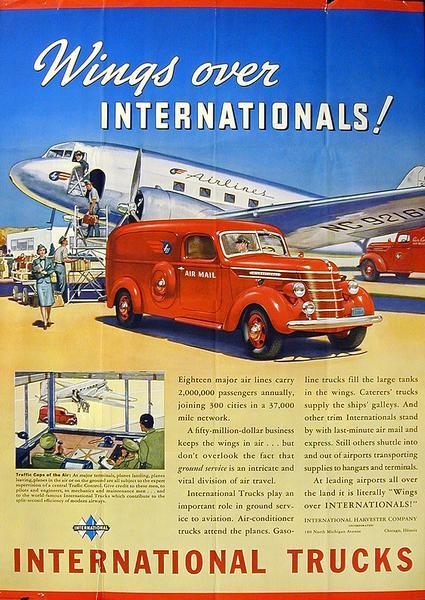

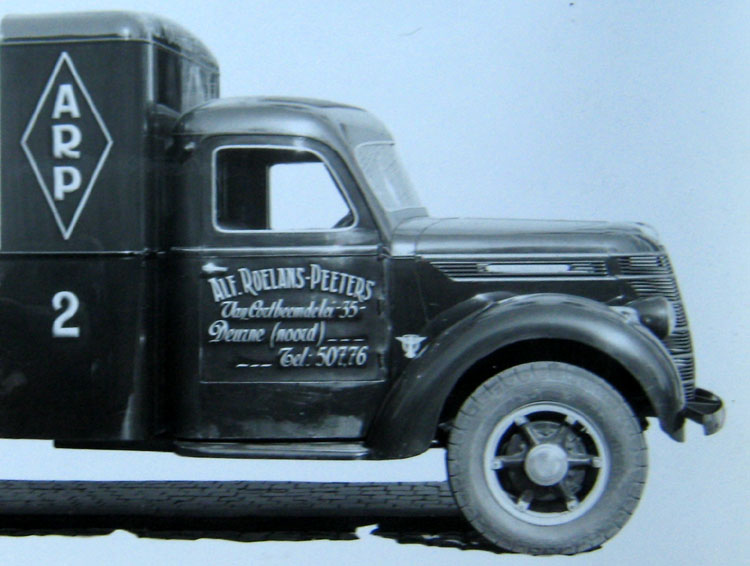

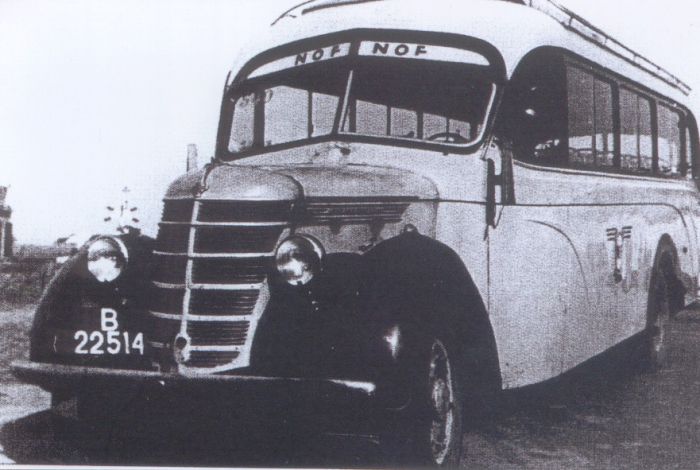

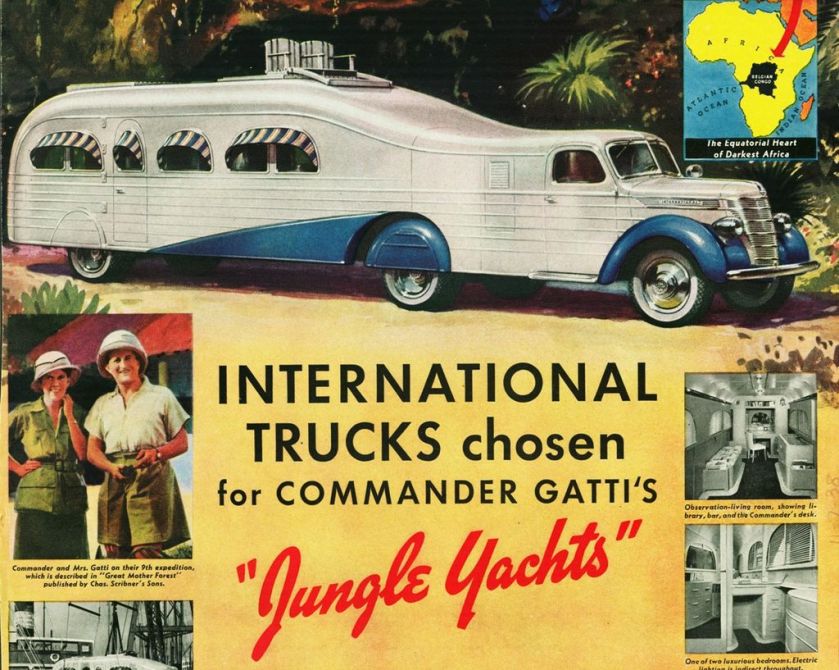

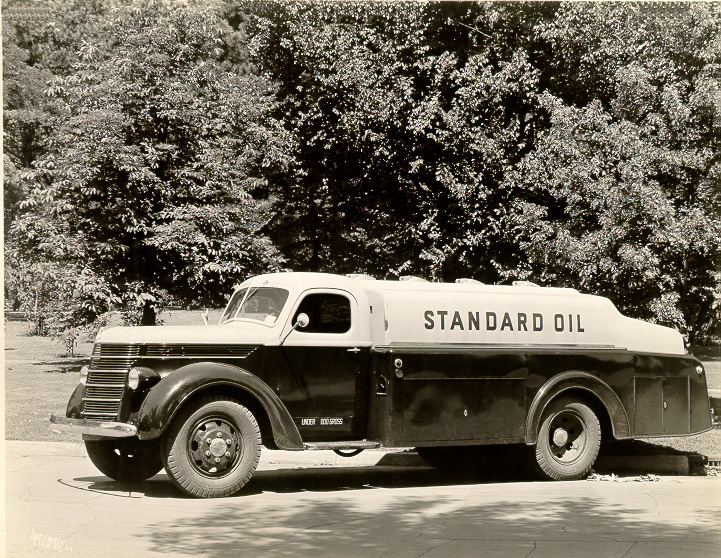

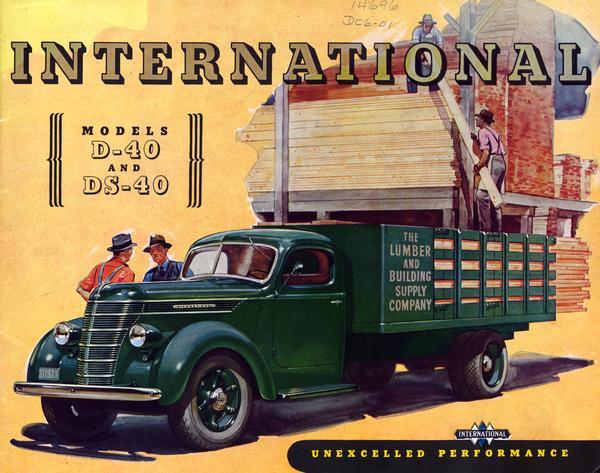

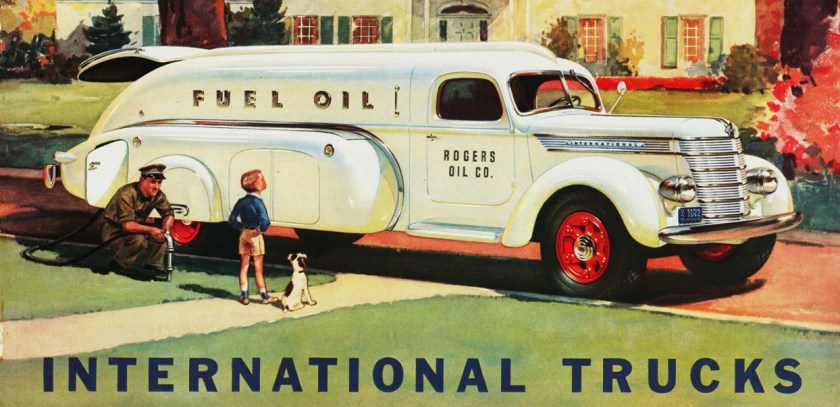

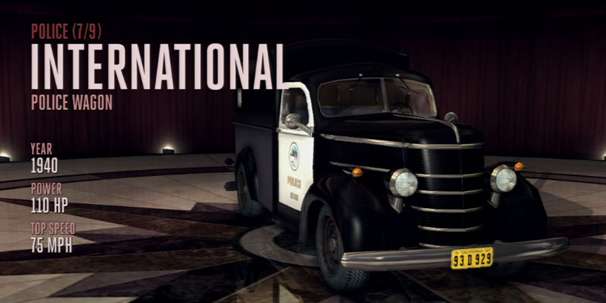

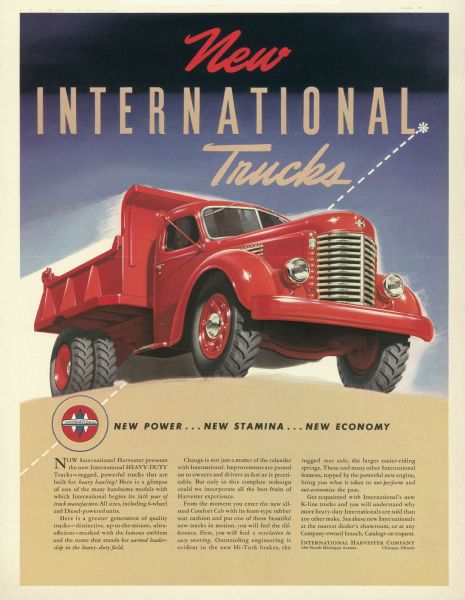

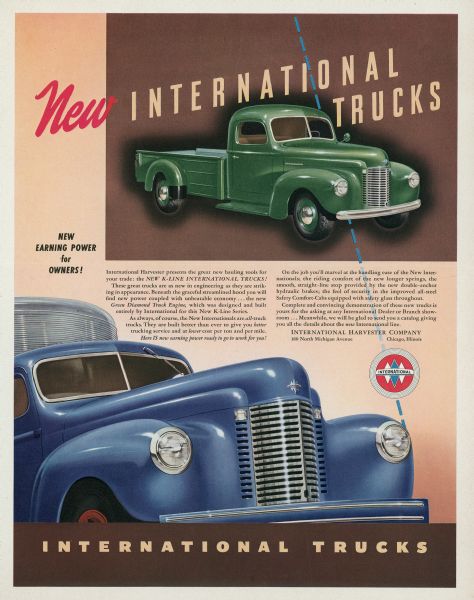

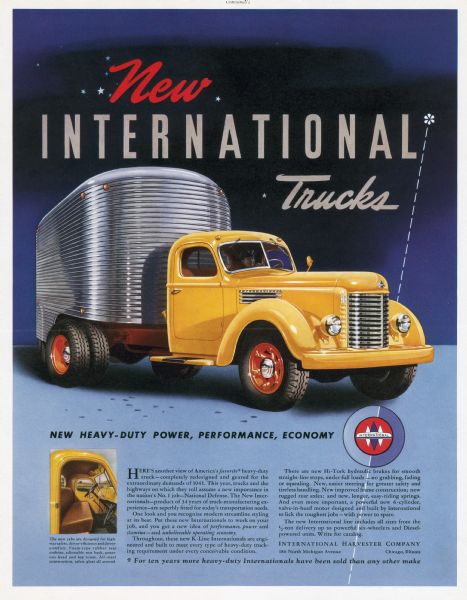

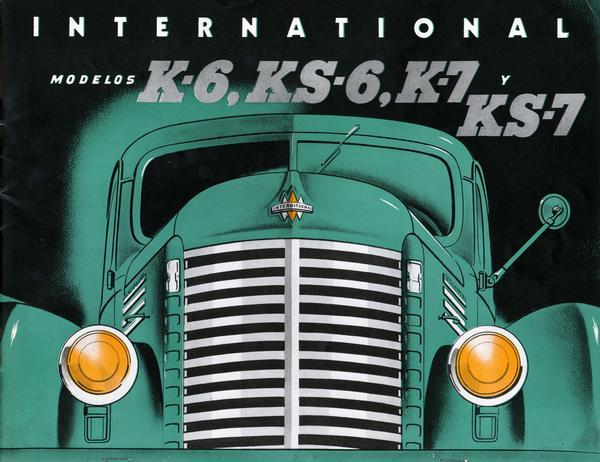

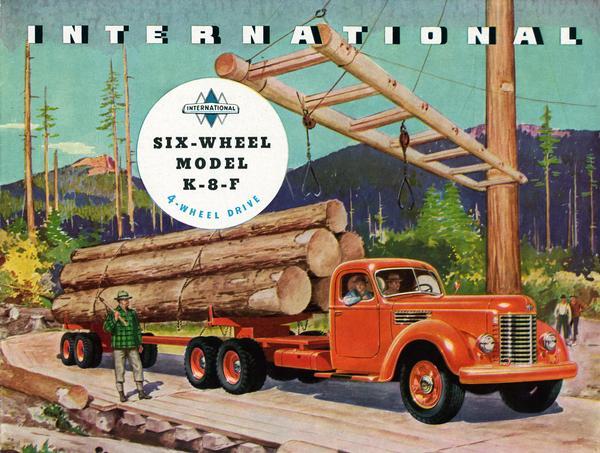

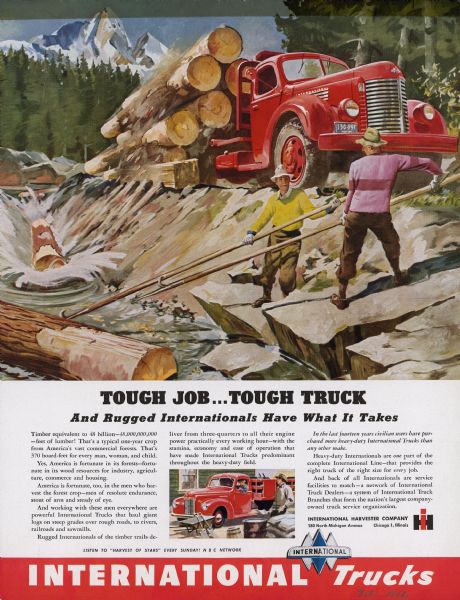

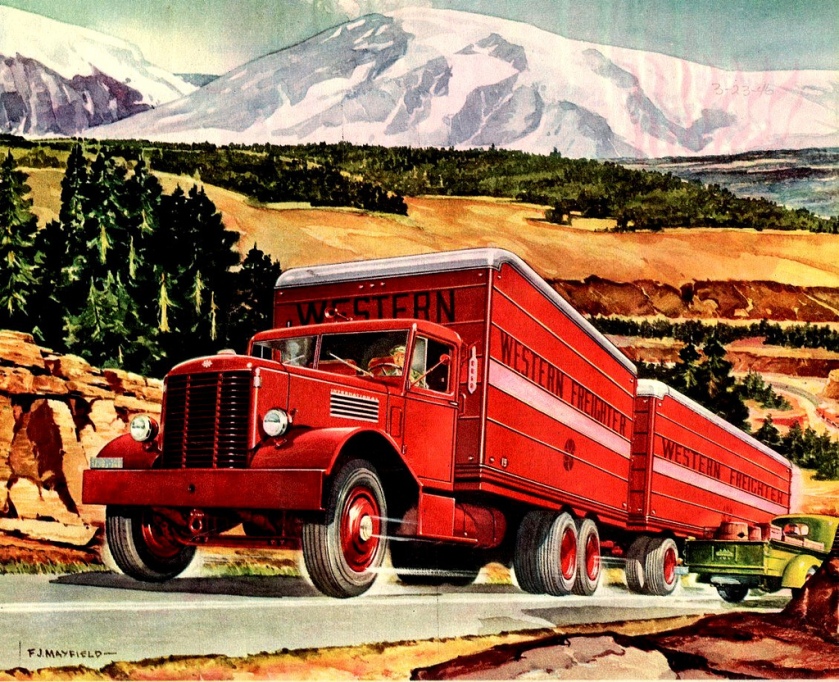

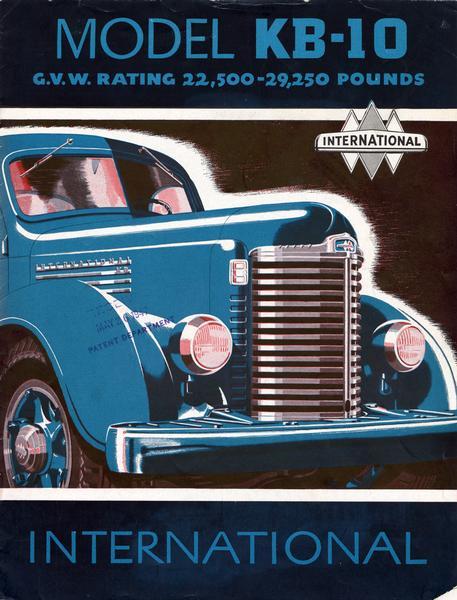

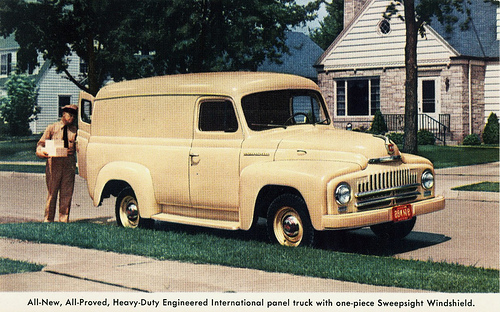

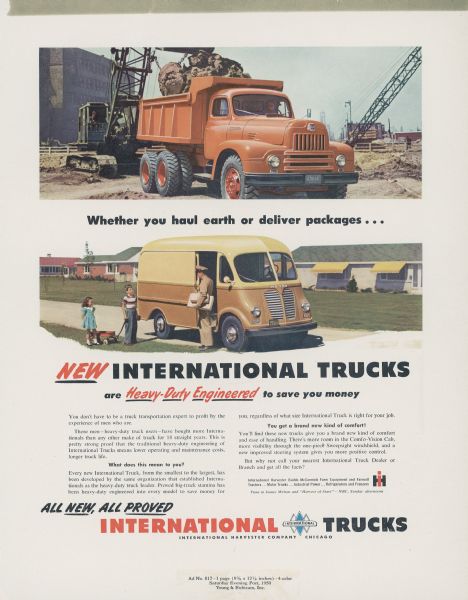

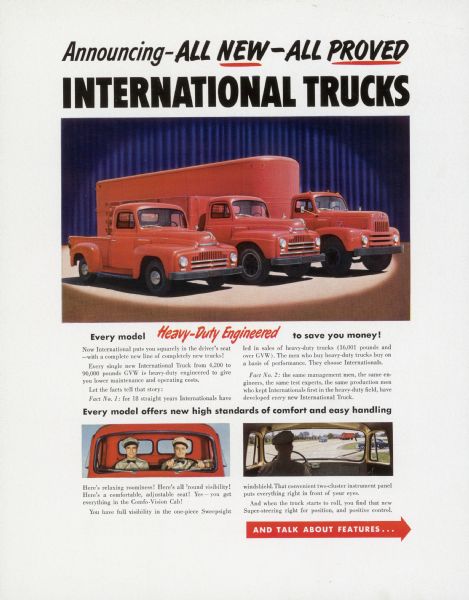

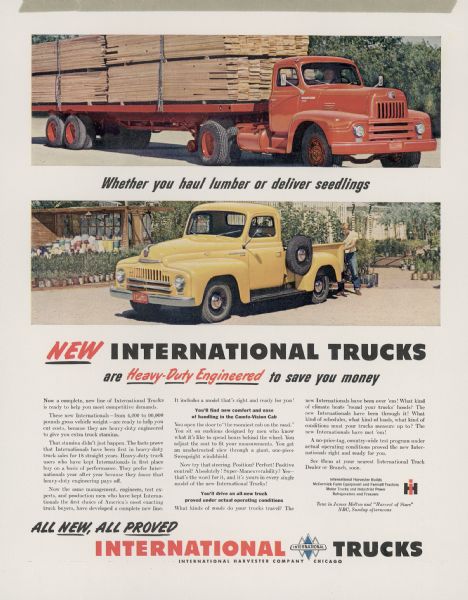

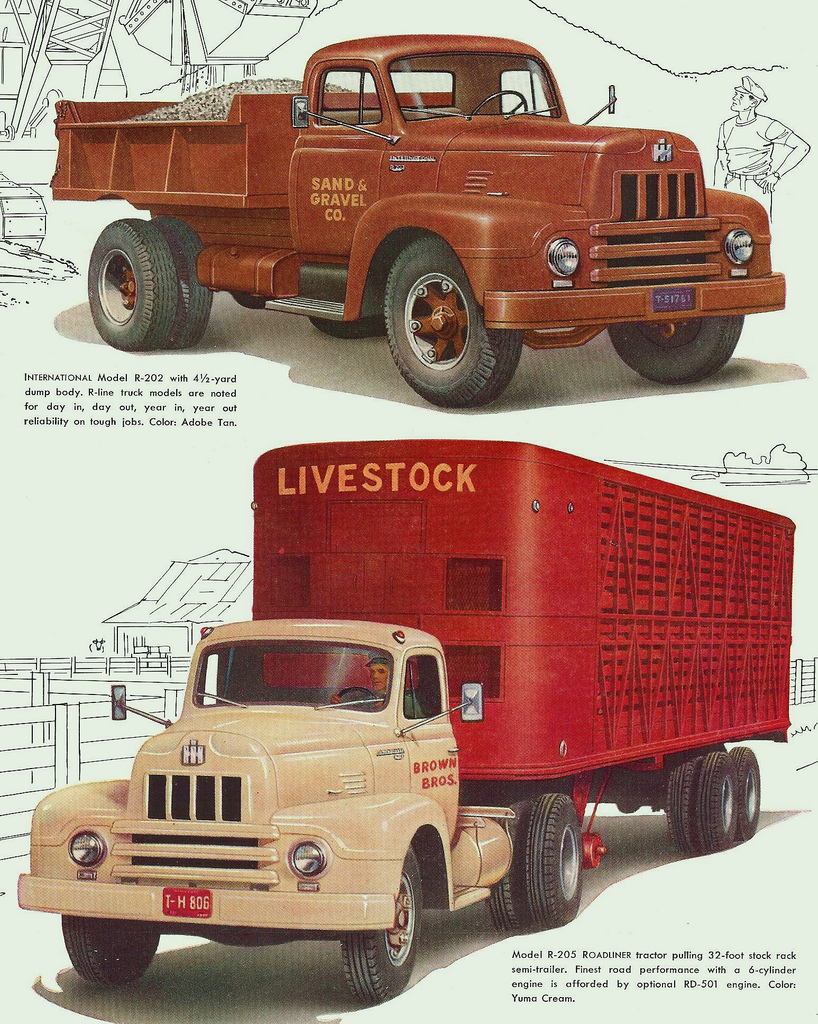

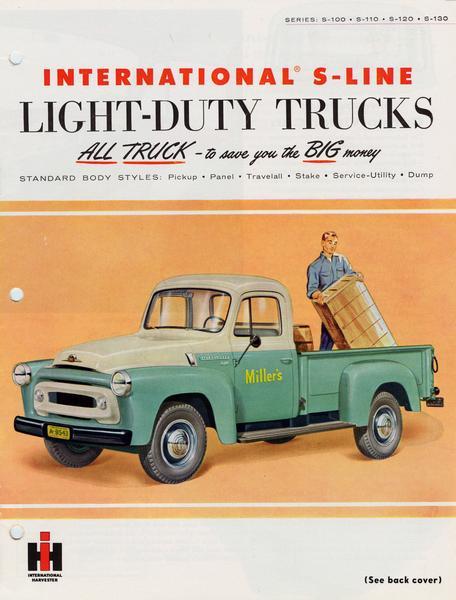

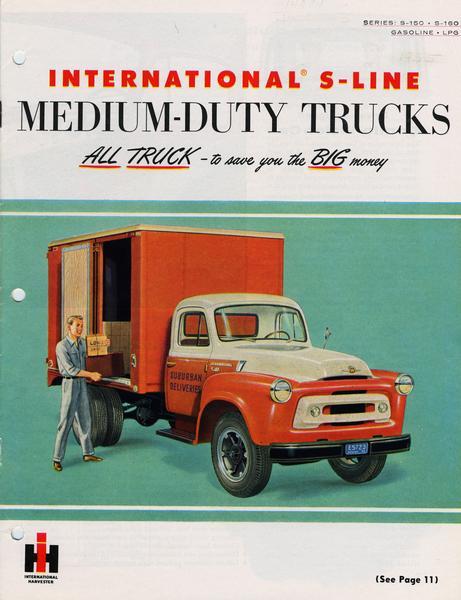

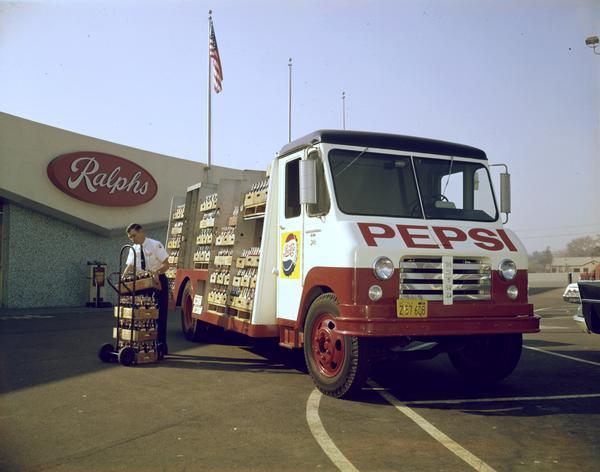

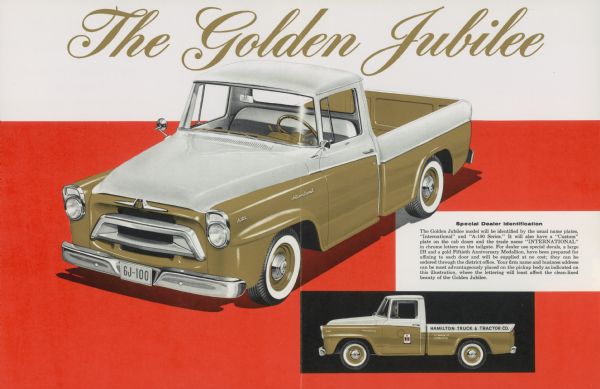

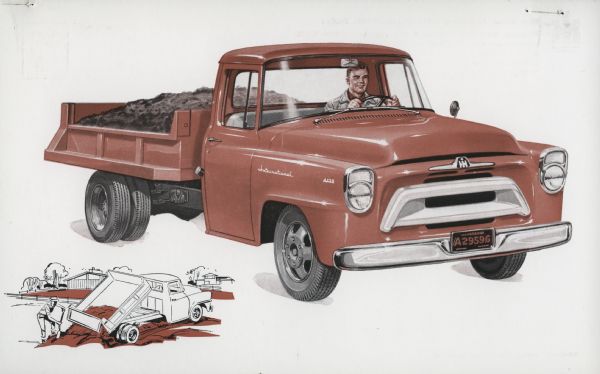

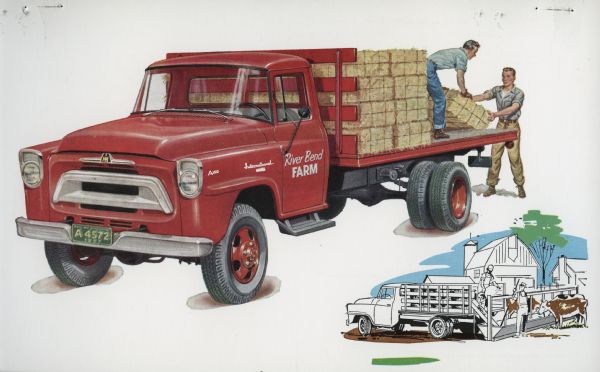

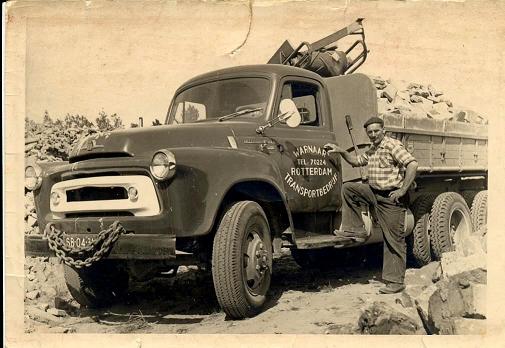

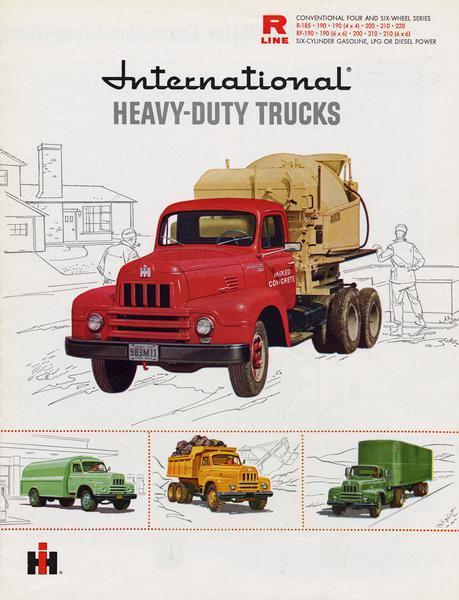

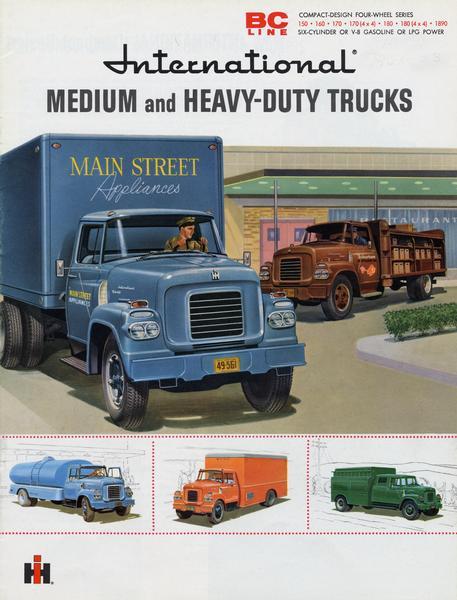

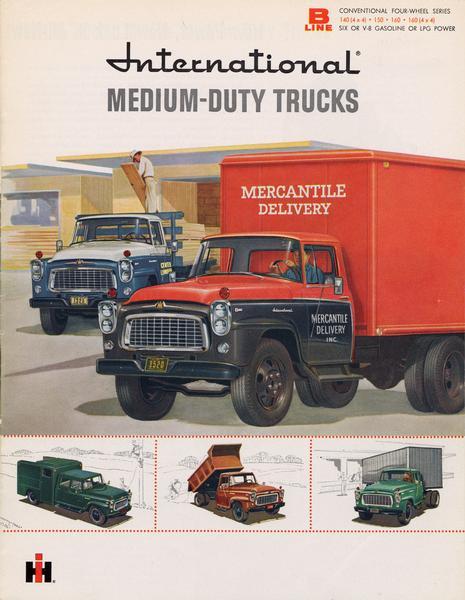

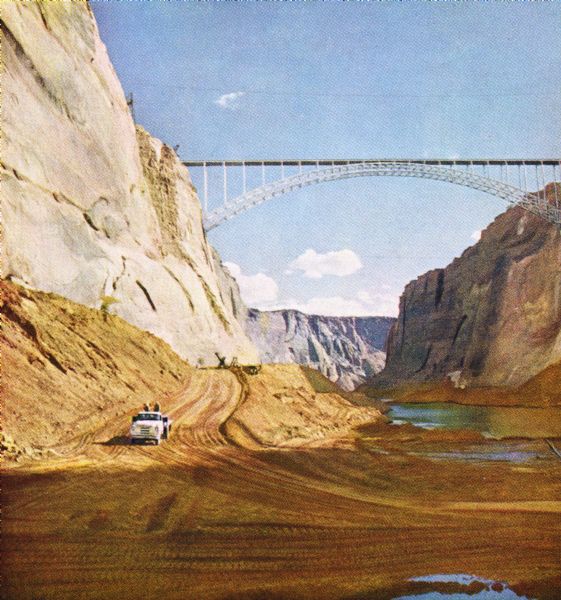

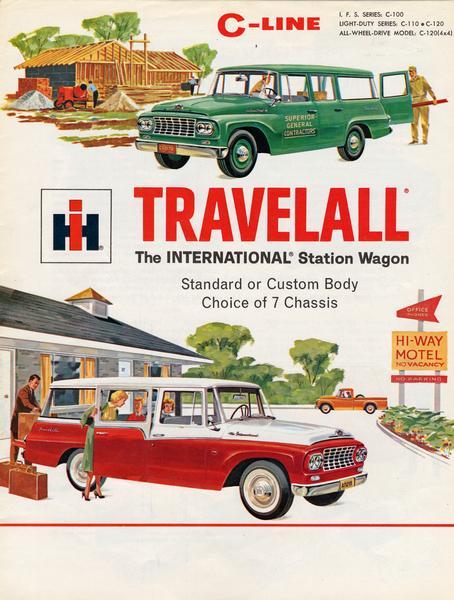

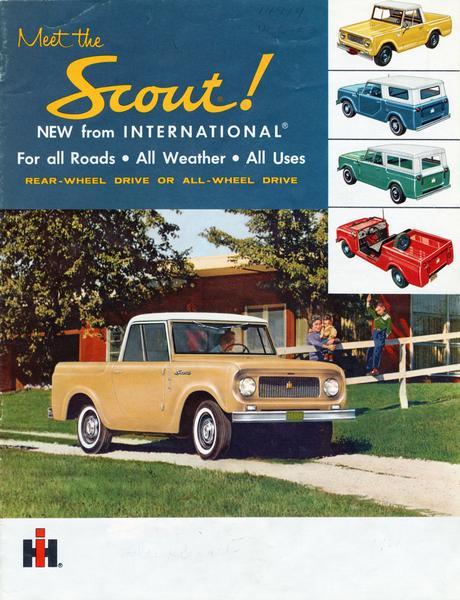

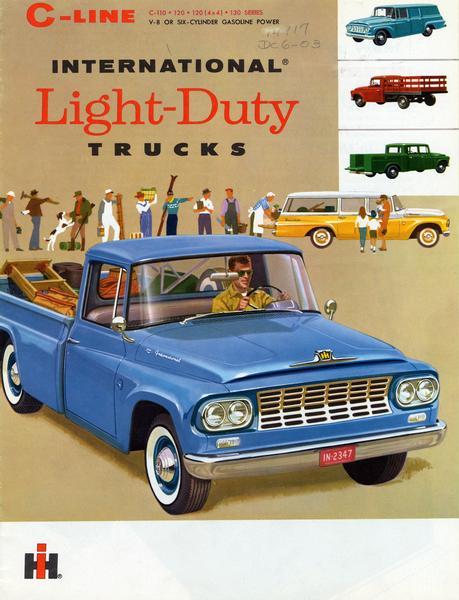

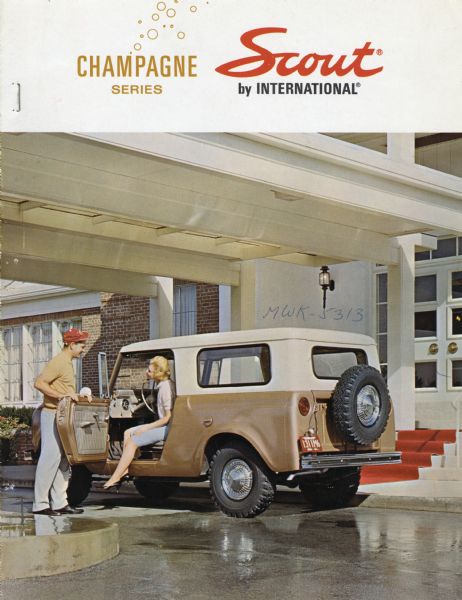

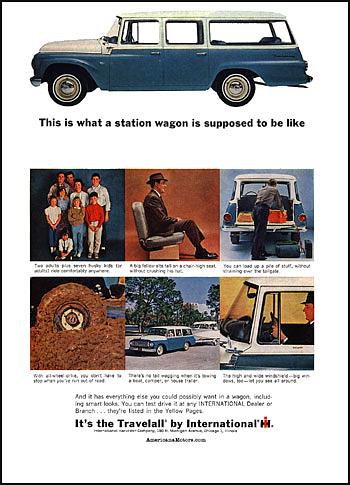

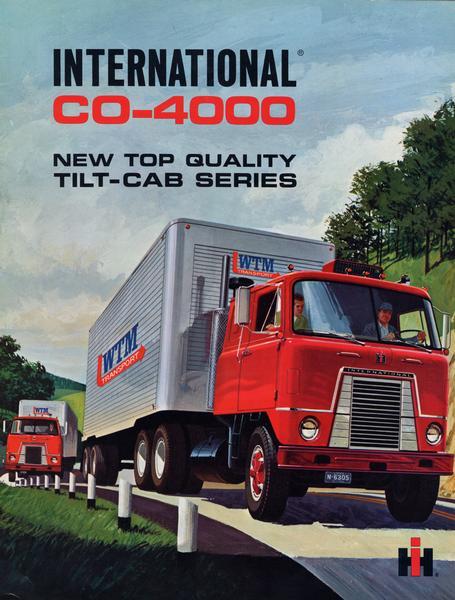

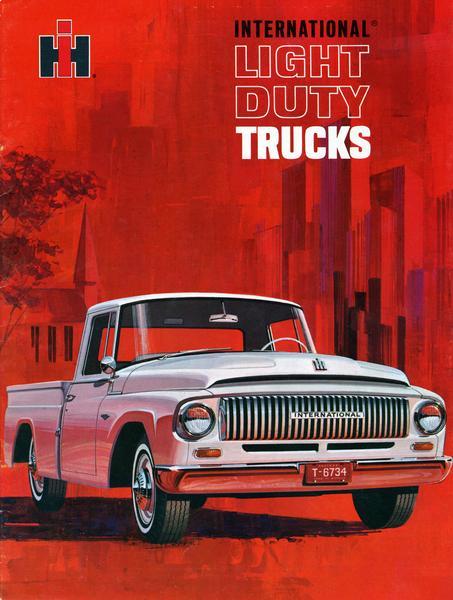

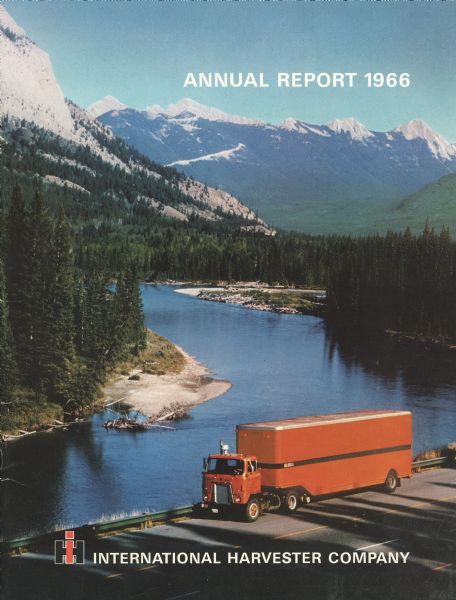

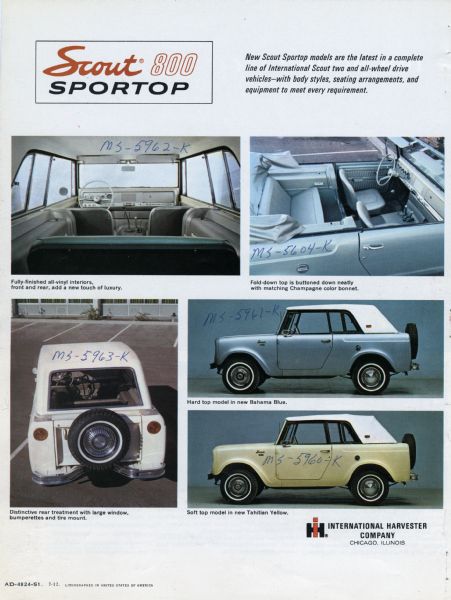

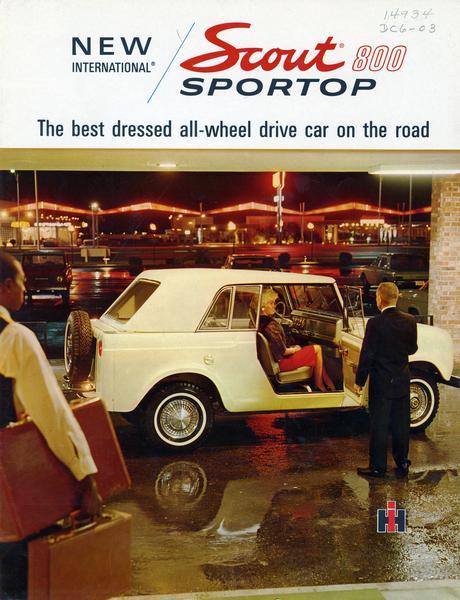

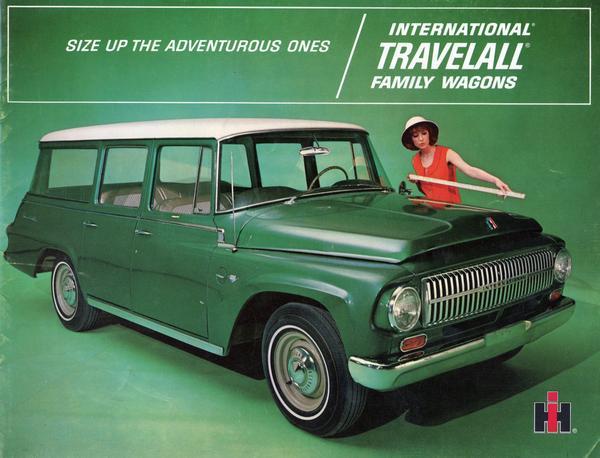

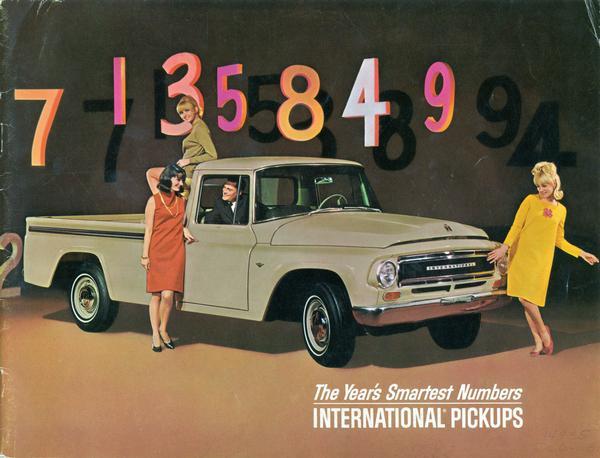

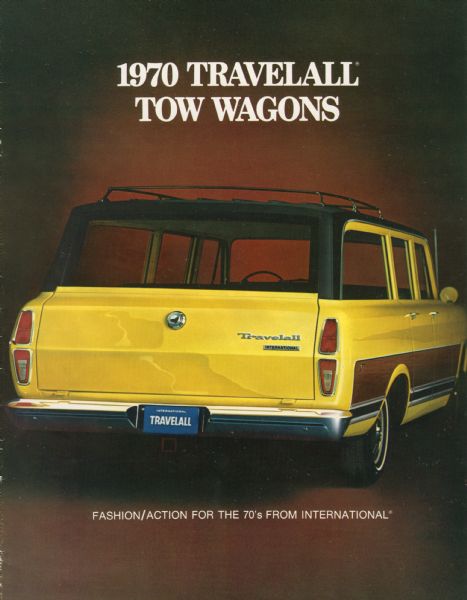

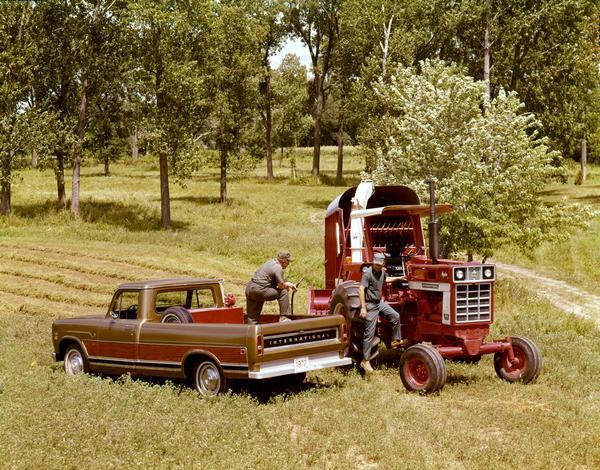

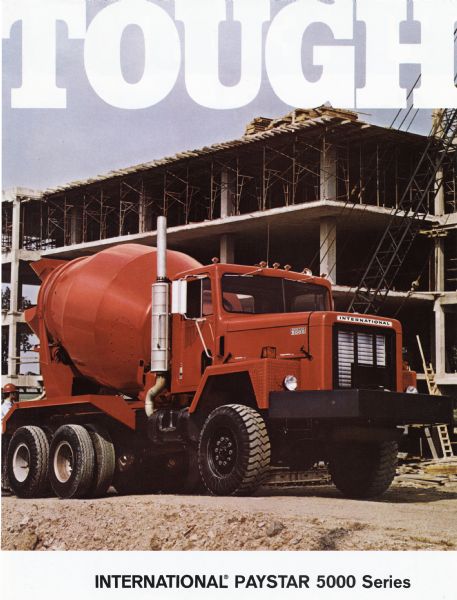

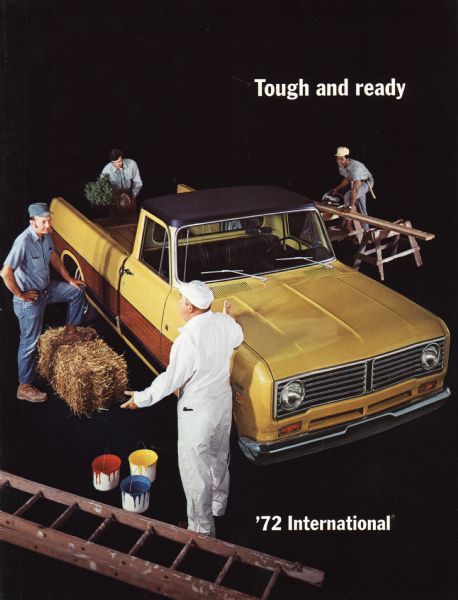

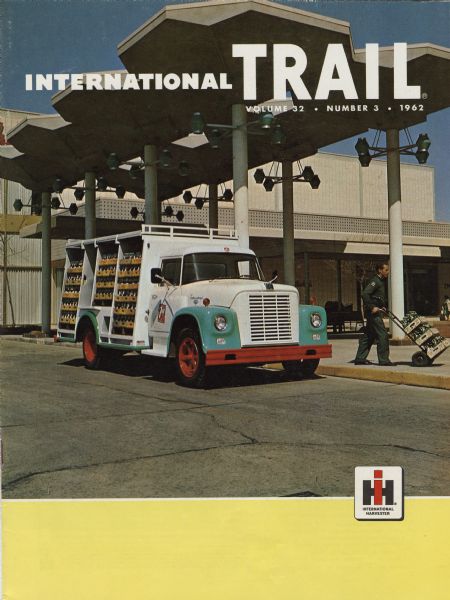

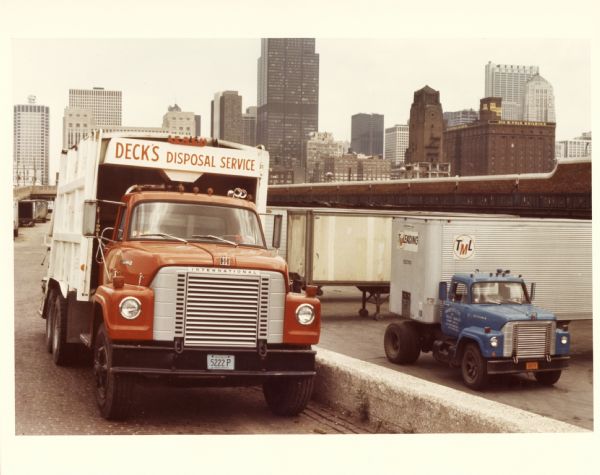

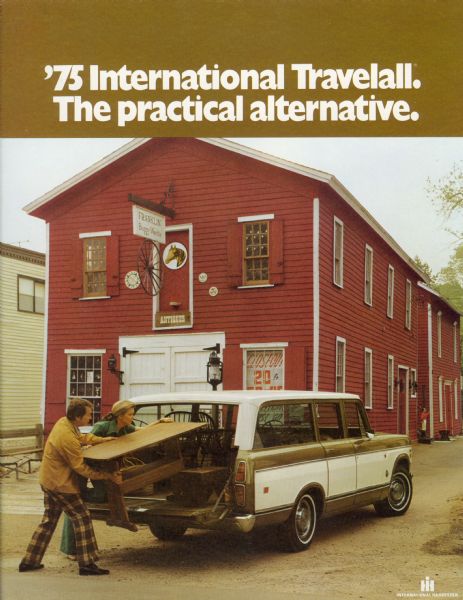

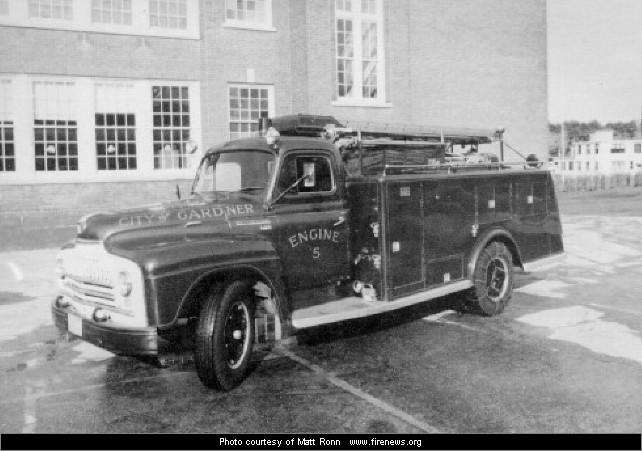

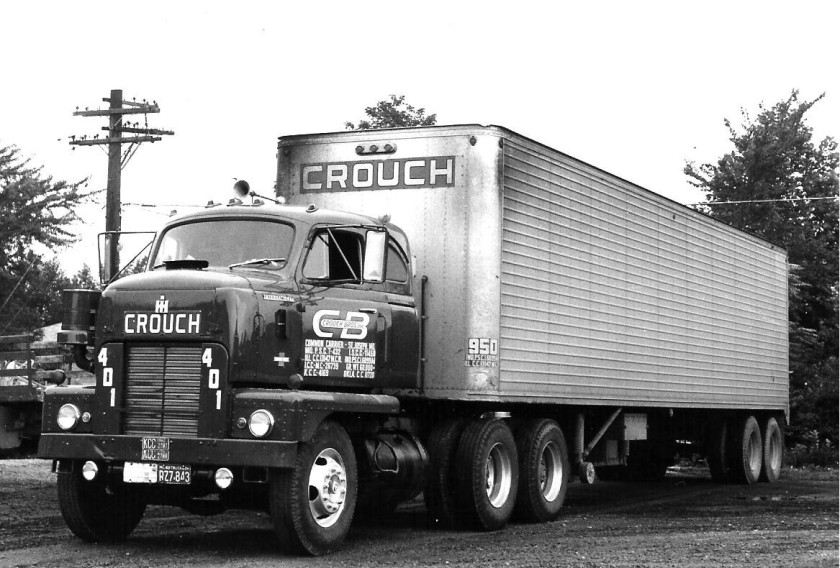

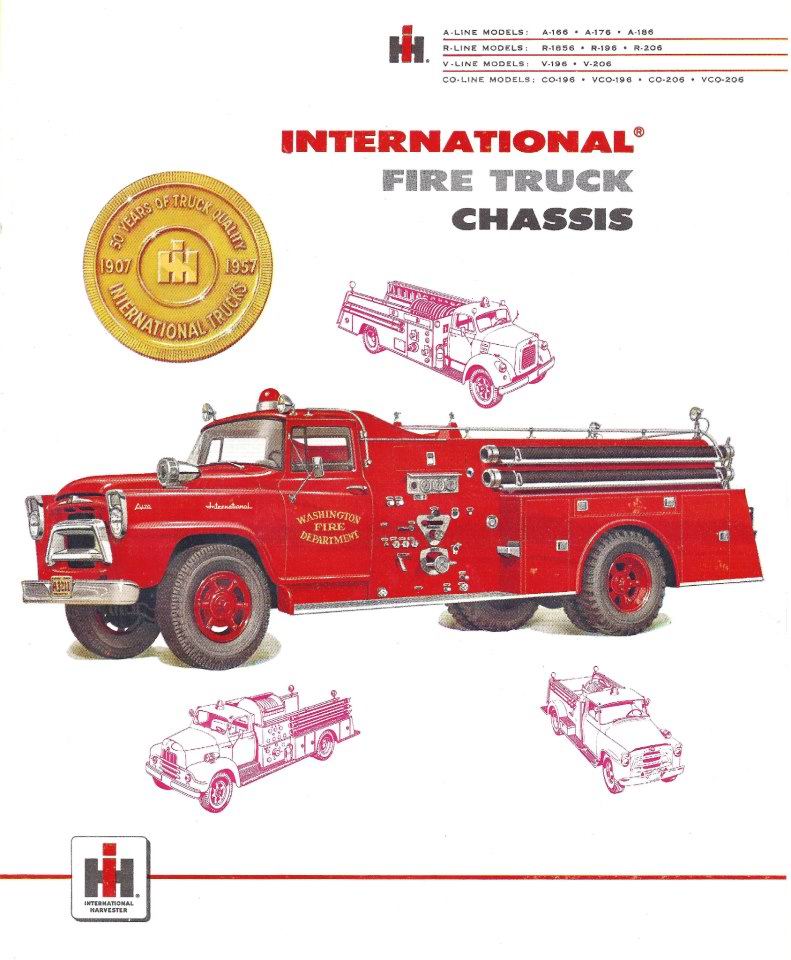

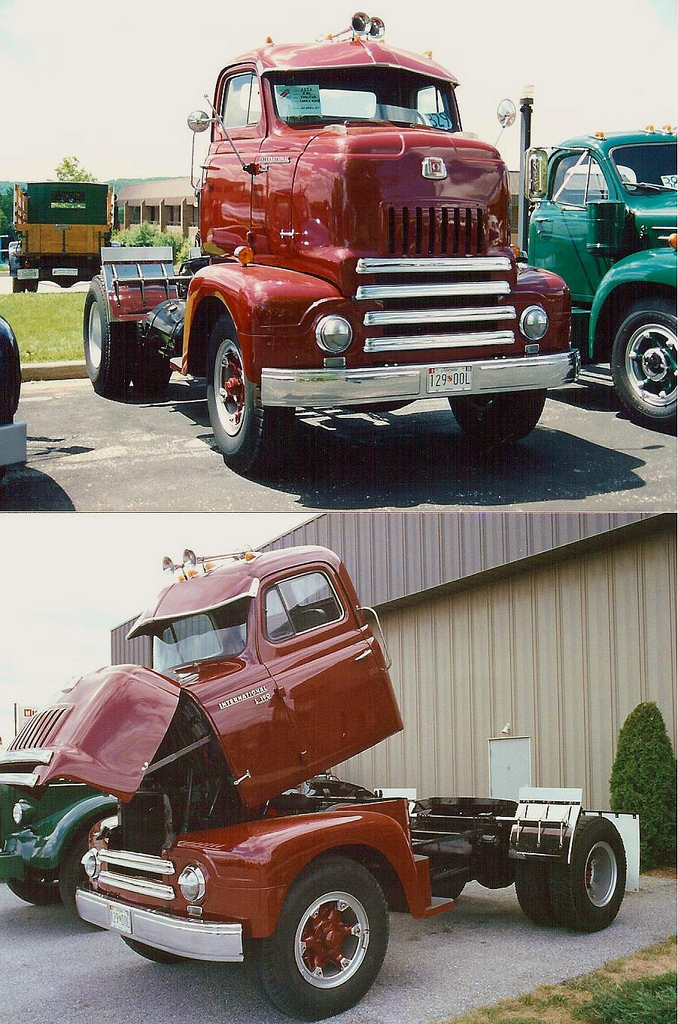

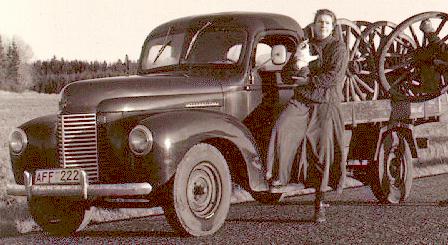

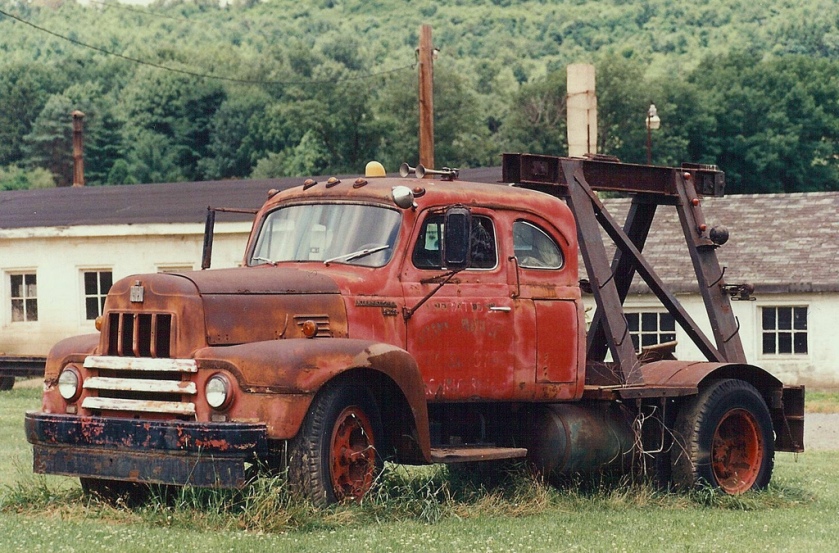

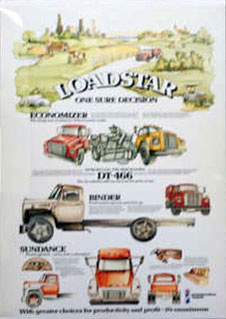

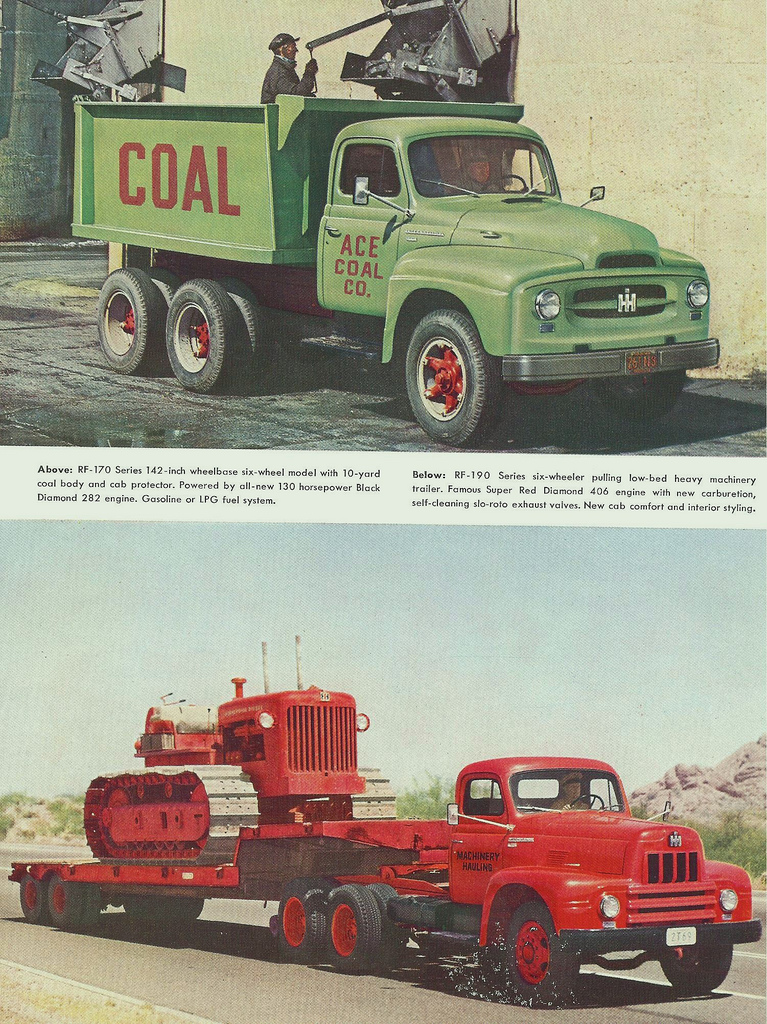

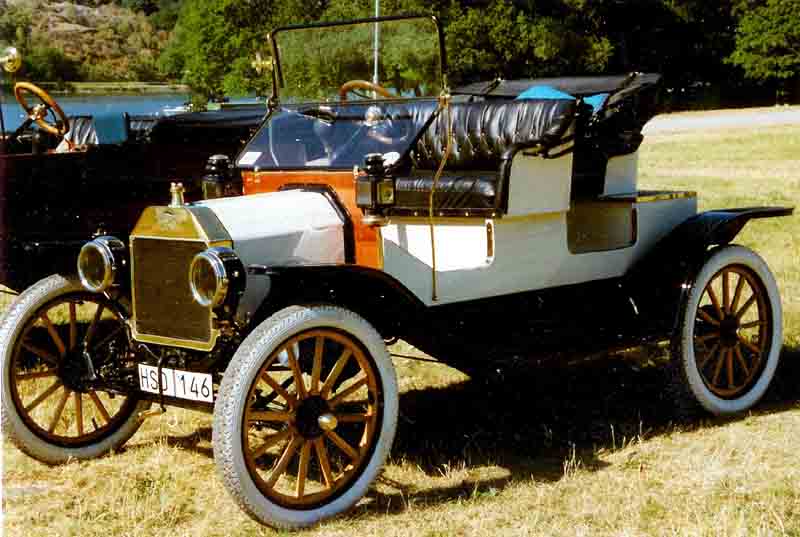

Images

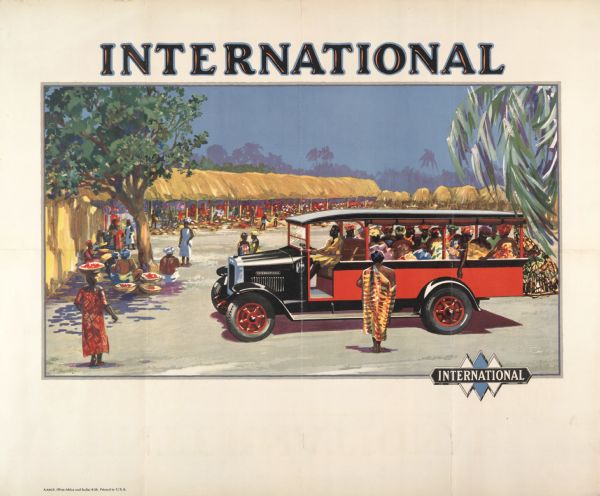

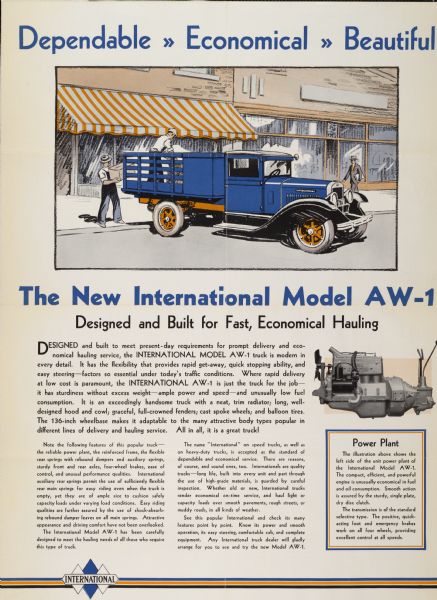

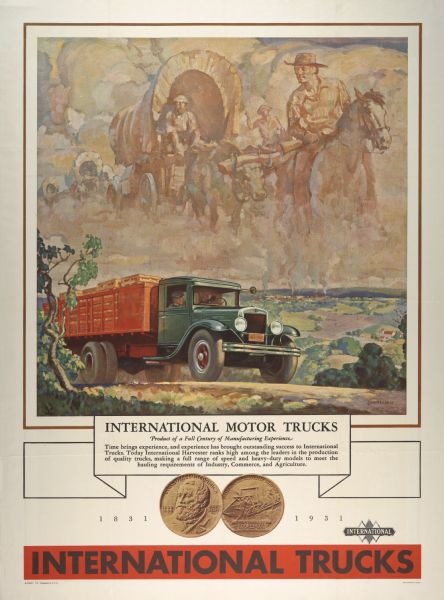

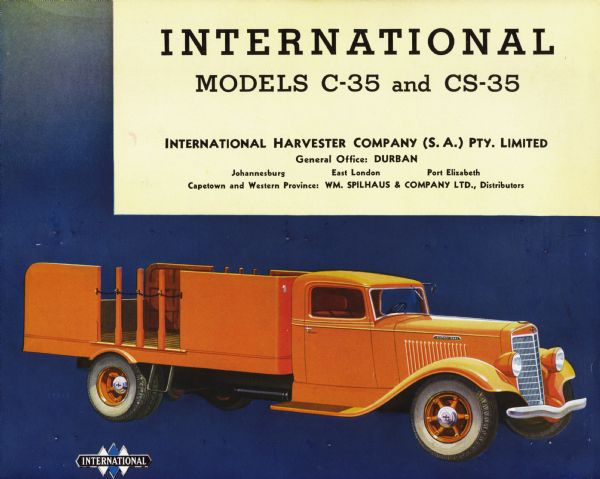

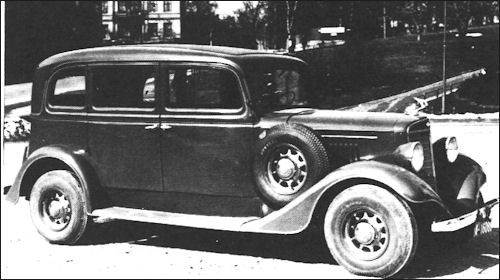

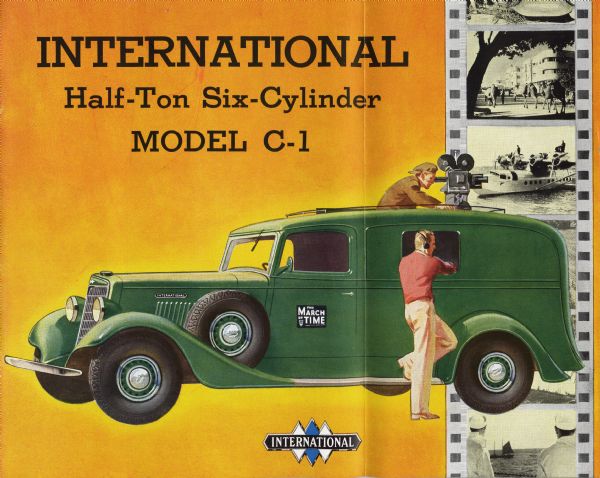

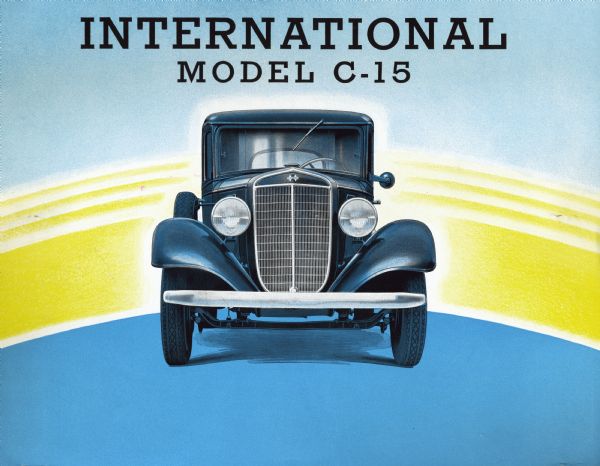

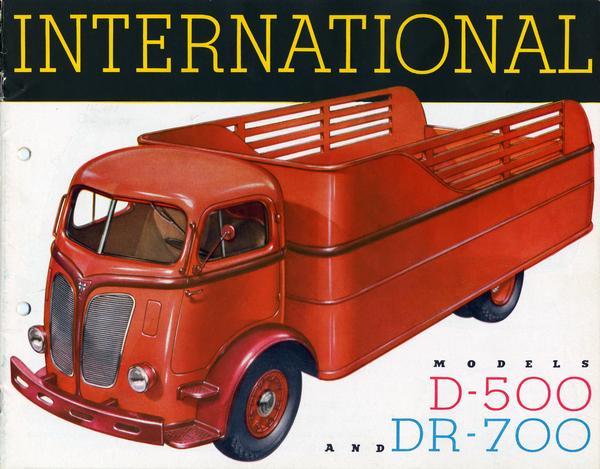

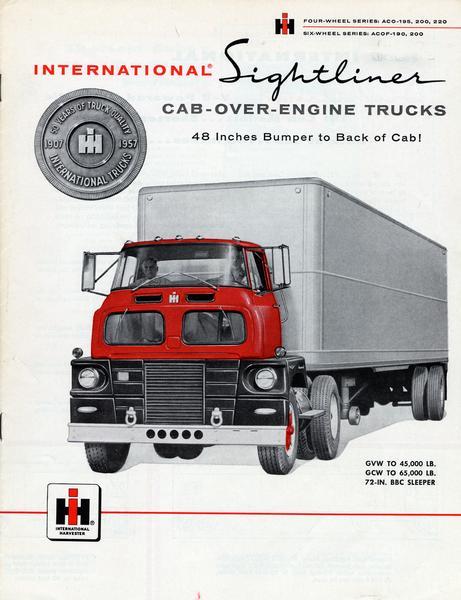

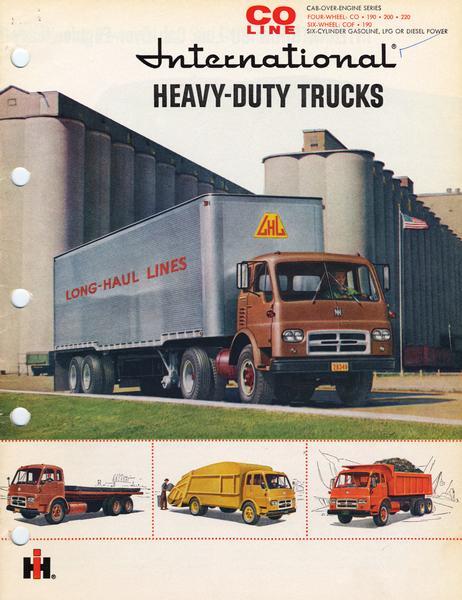

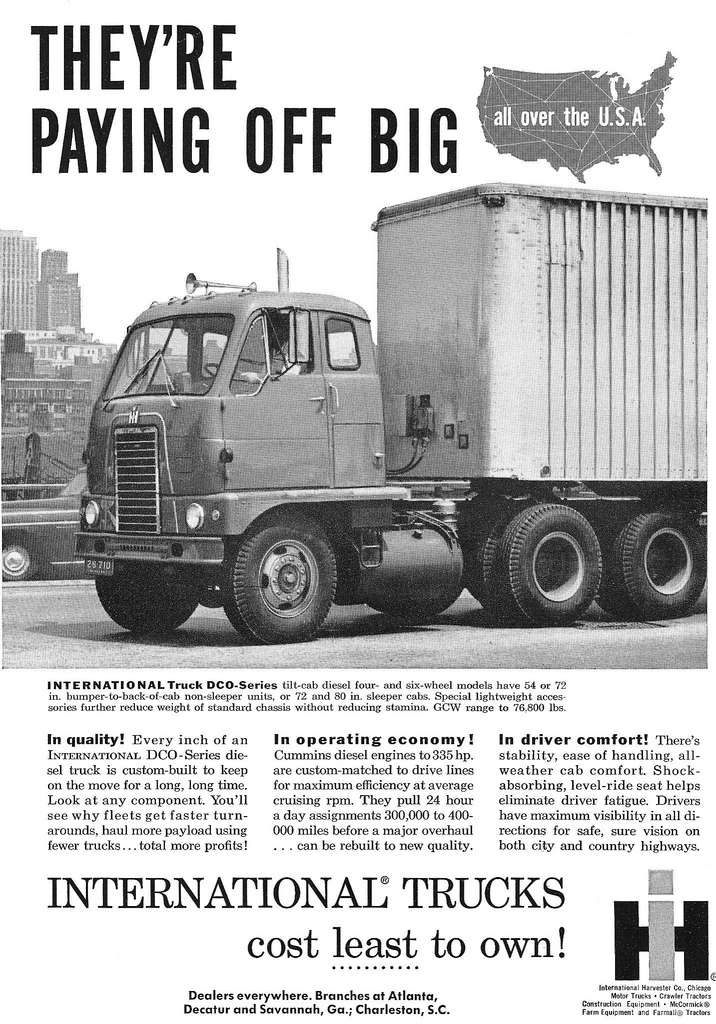

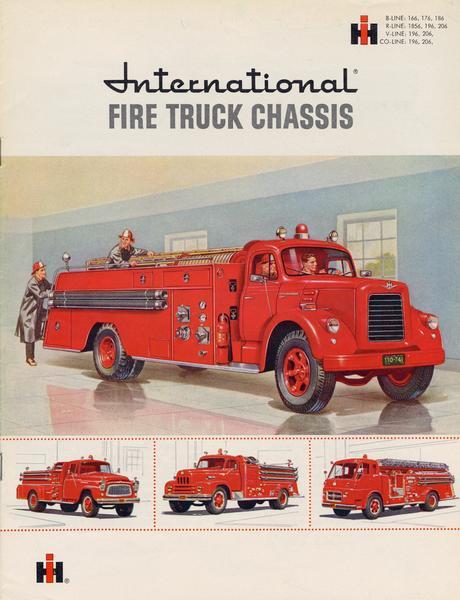

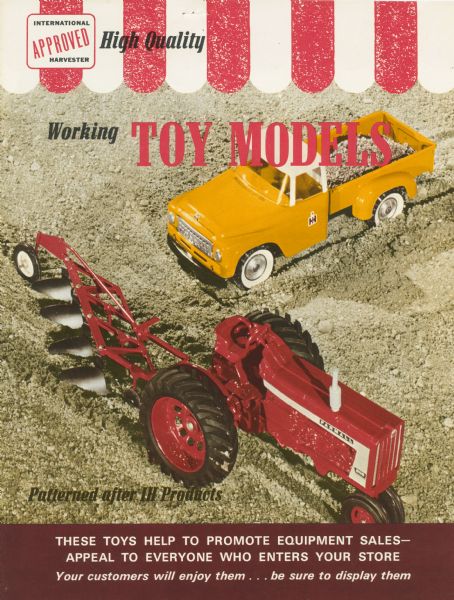

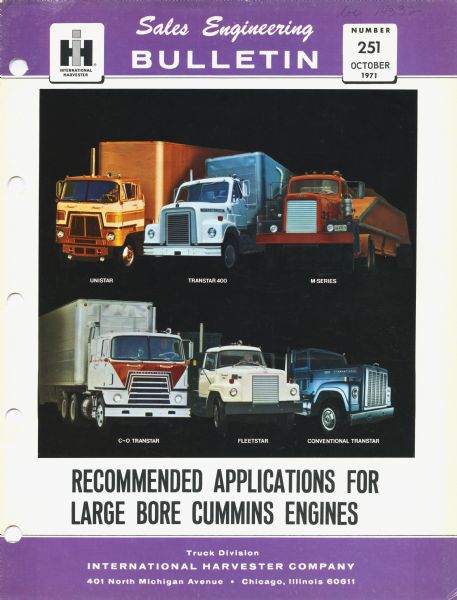

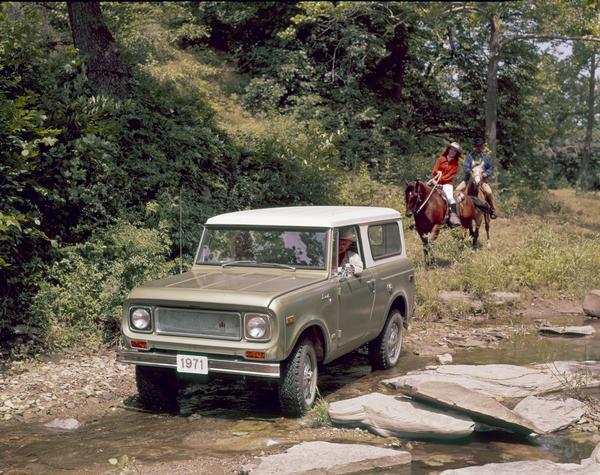

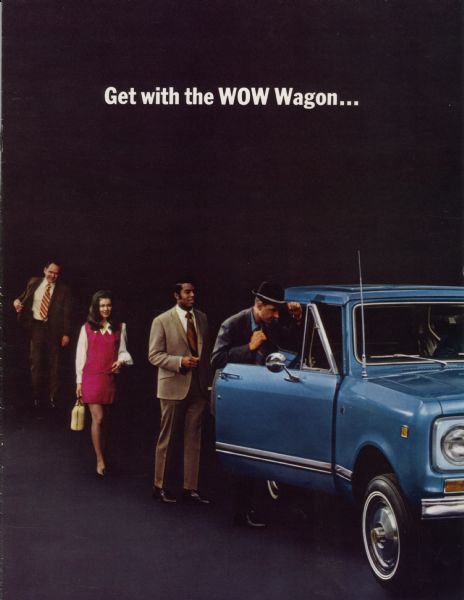

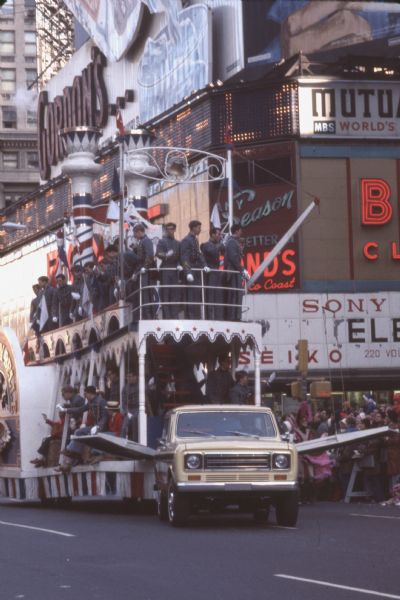

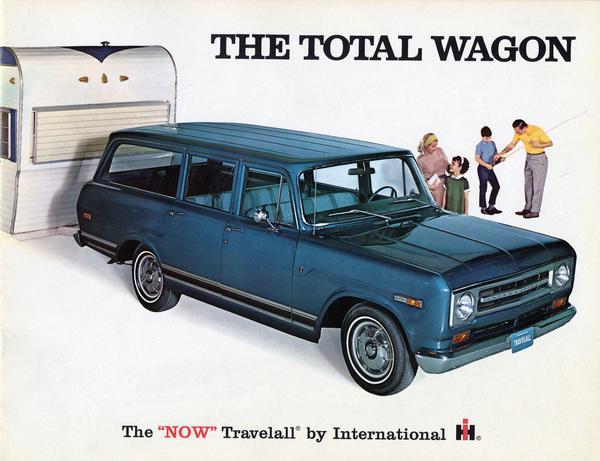

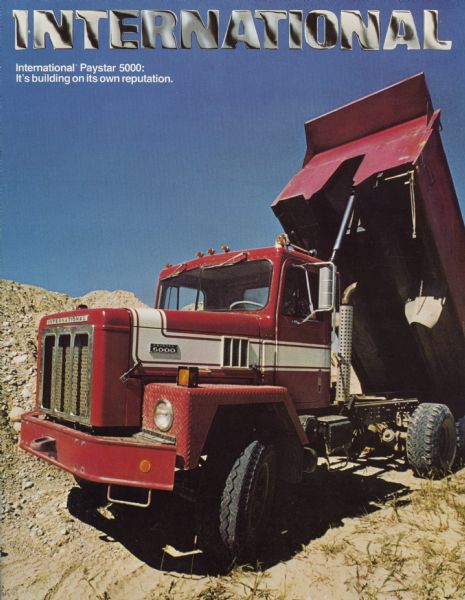

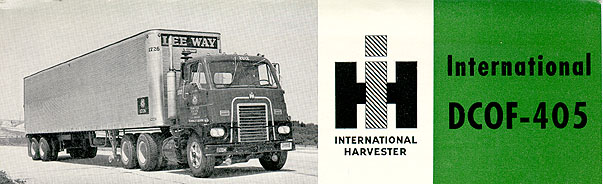

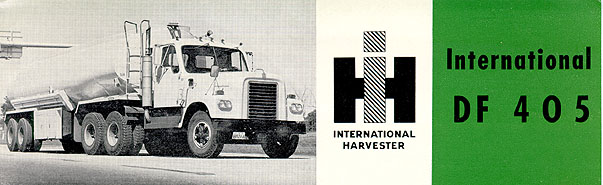

| Navistar International Vehicles | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

International

International  International

International