The Ford Motor Company (commonly referred to as simply Ford) is an American multinational automaker headquartered in Dearborn, Michigan, a suburb of Detroit. It was founded by Henry Ford and incorporated on June 16, 1903. The company sells automobiles and commercial vehicles under the Ford brand and most luxury cars under the Lincoln brand. Ford also owns Brazilian SUV manufacturer, Troller, and Australian performance car manufacturer FPV. In the past it has also produced tractors and automotive components. Ford owns a 2.1% stake in Mazda of Japan, an 8% stake in Aston Martin of the United Kingdom, and a 49% stake in Jiangling of China. It also has a number of joint-ventures, two in China (Changan Ford Mazda and Ford Lio Ho), one in Thailand (AutoAlliance Thailand), one in Turkey (Ford Otosan), and one in Russia (Ford Sollers). It is listed on the New York Stock Exchange and is controlled by the Ford family, although they have minority ownership. It is described by Forbes as “the most important industrial company in the history of the United States.”

Ford introduced methods for large-scale manufacturing of cars and large-scale management of an industrial workforce using elaborately engineered manufacturing sequences typified by moving assembly lines; by 1914 these methods were known around the world as Fordism. Ford’s former UK subsidiaries Jaguar and Land Rover, acquired in 1989 and 2000 respectively, were sold to Tata Motors in March 2008. Ford owned the Swedish automaker Volvo from 1999 to 2010. In 2011, Ford discontinued the Mercury brand, under which it had marketed entry-level luxury cars in the United States, Canada, Mexico, and the Middle East since 1938.

Ford is the second-largest U.S.-based automaker (preceded by General Motors) and the fifth-largest in the world based on 2010 vehicle sales. At the end of 2010, Ford was the fifth largest automaker in Europe. Ford is the eighth-ranked overall American-based company in the 2010 Fortune 500 list, based on global revenues in 2009 of $118.3 billion. In 2008, Ford produced 5.532 million automobiles and employed about 213,000 employees at around 90 plants and facilities worldwide.

The company went public in 1956 but the Ford family, through special Class B shares, still retain 40 percent voting rights.

History

Henry Ford (ca. 1919)

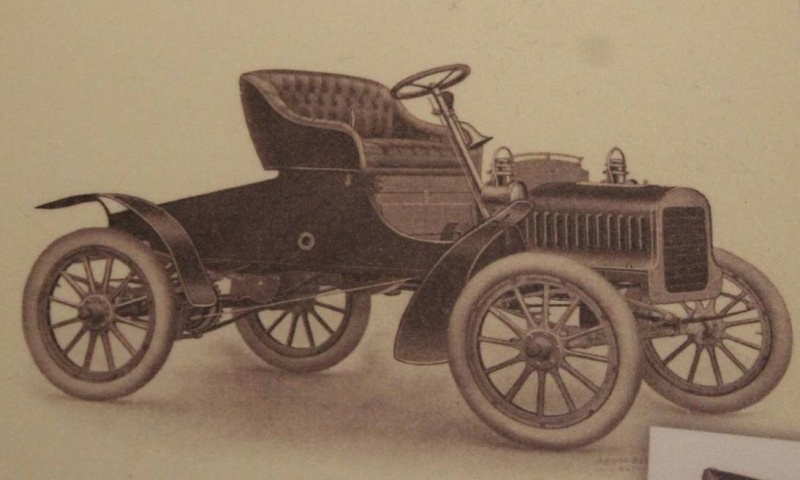

Ford Model N

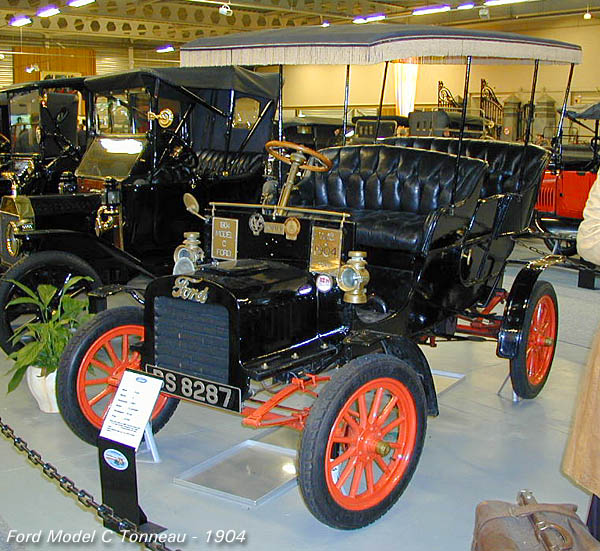

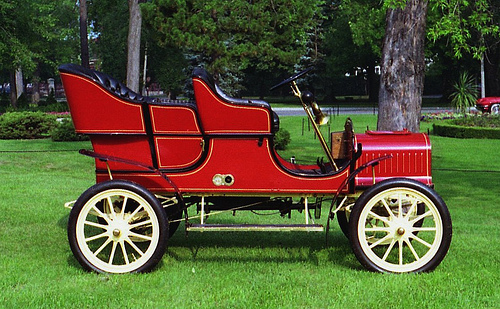

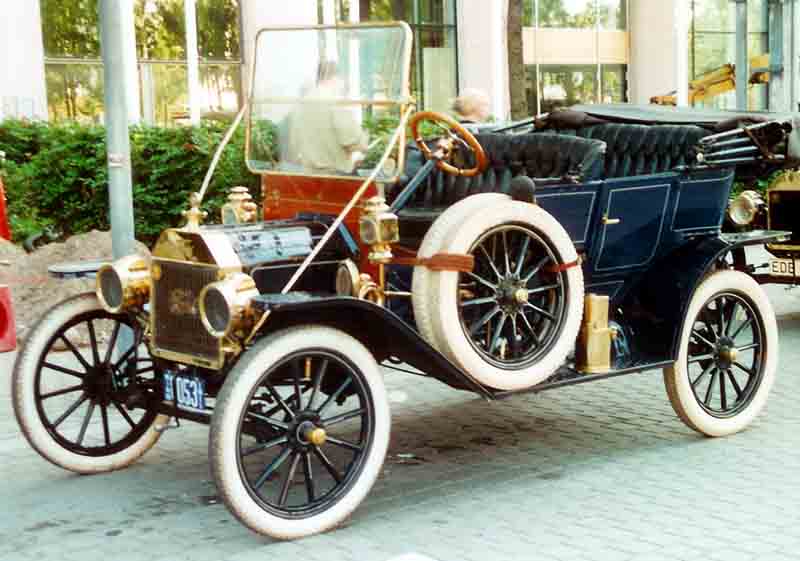

The Ford Model N is an automobile that was produced by the Ford Motor Company. It was introduced in 1906 as a successor to the Models A and C as the company’s inexpensive entry-level line.

The Model N diverged from its predecessors in that it was a front-engine car with a 4-cylinder engine. The 15 hp straight-4 drove the rear wheels via a long shaft. This was also the first American car to use vanadium steel. The car had a wheelbase size of 84 in (2.1 m).

A successful model, 7000 cars were made until production ended in 1908. At US$500 the car was viewed as highly affordable at the time; by contrast, the high-volume Oldsmobile Runabout went for $650, Western‘s Gale Model A was $500, the Brush Runabout $485, the Black went for as low as $375, and the Success hit the amazingly low $250. Maroon was the only factory color for the Model N.

Model R

The Model R was a higher trim level of the Model N with a larger body, wheels covered by full cycle fenders, running boards, and an oil lamp. Model R was $750, $150 above the $600 base Model N. The Model R was only produced in 1907, from April through October, and 2500 were sold. Its color was red.

Model S

The Model S was another adaptation of the Model N. Ford’s last US market right-hand-drive model, it featured a more modern cowl, with hood and fenders that flowed into full running boards. Another notable difference was the optional extra third mother-in-law seat behind the front bench. The basic model sold for $700. Extras such as a convertible top, gas lamps, as well as umbrella holders were available. 3750 cars were sold between 1907 and 1909.

20th century

Henry Ford’s first attempt at a car company under his own name was the Henry Ford Company on November 3, 1901, which became the Cadillac Motor Company on August 22, 1902, after Ford left with the rights to his name. The Ford Motor Company was launched in a converted factory in 1903 with $28,000 in cash from twelve investors, most notably John and Horace Dodge (who would later found their own car company). During its early years, the company produced just a few cars a day at its factory on Mack Avenue in Detroit, Michigan. Groups of two or three men worked on each car, assembling it from parts made mostly by supplier companies contracting for Ford. Within a decade the company would lead the world in the expansion and refinement of the assembly line concept; and Ford soon brought much of the part production in-house in a vertical integration that seemed a better path for the era.

Henry Ford was 39 years old when he founded the Ford Motor Company, which would go on to become one of the world’s largest and most profitable companies, as well as being one to survive the Great Depression. As one of the largest family-controlled companies in the world, the Ford Motor Company has been in continuous family control for over 100 years.

After the first modern automobile was already created in the year 1886 by German inventor Carl Benz (Benz Patent-Motorwagen), more efficient production methods were needed to make the automobile affordable for the middle-class; which Ford contributed to, for instance by introducing the first moving assembly line in 1913.

In 1908 Ford introduced the first engine with a removable cylinder head, in the Model T.

Ford Model T

(Redirected from Model T)

| Ford Model T |

1919 Ford Model T Coupe

|

| Overview |

| Manufacturer |

Ford Motor Company |

| Production |

1908–1927 |

| Assembly |

- Detroit, Michigan, U.S.;

- Highland Park, Michigan, U.S.;

- Buffalo, New York, U.S.;

- Los Angeles, California, U.S.;

- Minneapolis, Minnesota, U.S.;

- St. Louis, Missouri, U.S.;

- St. Paul, Minnesota, U.S.;

- Dothan, Alabama, U.S.;

- Cincinnati, Ohio, U.S.;

- San Francisco, California, U.S.;

- Cleveland, Ohio, U.S.;

- Columbus, Ohio, U.S.;

- Buenos Aires, Argentina;

- Santiago, Chile;

- Geelong, Australia;

- São Bernardo do Campo, Brazil;

- Toronto, Canada;

- Walkerville, Canada;

- Copenhagen, Denmark;

- Manchester, United Kingdom;

- Berlin, Germany;

- Cork, Ireland;

- Cádiz, Spain

|

| Designer |

Henry Ford, Childe Harold Wills, Joseph A. Galamb and Eugene Farkas |

| Body and chassis |

| Class |

Full-size Ford, economy car |

| Body style |

- 2-door touring (1909–11)

- 3-door touring (1912–1925)

- 4-door touring (1926–1927)

- no door roadster (1909–11)

- 1-door roadster(1912–1925)

- 2-door roadster (1926–1927)

- roadster pickup (1925–1927)

- 2-door coupé (1909–1912, 1917–1927)

- 2-door Coupelet (1915–17)

- Town car (1909–1918)

- C-cab wagon (1912)

- 2-(Center) door sedan (1915–1923)

- 2-door sedan (1924–1927)

- 4-door sedan (1923–1927)

- Separate chassis were available all years from independent coachbuilders

|

| Layout |

FR layout |

| Powertrain |

| Engine |

177 C.I.D. (2.9 L) 20 hp I4 |

| Transmission |

2-speed planetary gear |

| Dimensions |

| Wheelbase |

100.0 in (2,540 mm) |

| Length |

134 in (3,404 mm) |

| Curb weight |

1,200 pounds (540 kg) |

| Chronology |

| Predecessor |

Ford Model S |

| Successor |

Ford Model A |

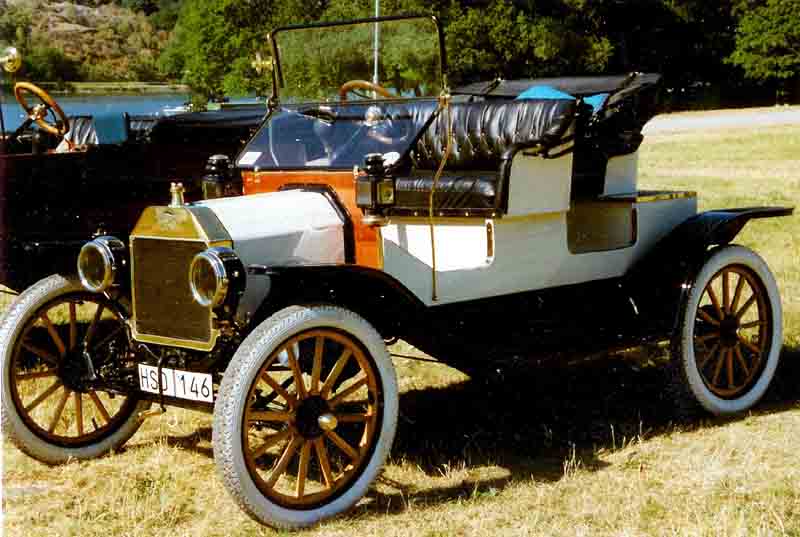

The Ford Model T (colloquially known as the Tin Lizzie, Tin Lizzy, T‑Model Ford, Model T, or T) is an automobile that was produced by Henry Ford‘s Ford Motor Company from October 1, 1908, to May 26, 1927. It is generally regarded as the first affordable automobile, the car that opened travel to the common middle-class American; some of this was because of Ford’s efficient fabrication, including assembly lineproduction instead of individual hand crafting.

The Ford Model T was named the most influential car of the 20th century in the 1999 Car of the Century competition, ahead of the BMC Mini, Citroën DS, and Volkswagen Type 1, and still makes top ten list of most sold cars (ranked nr. 8) as of 2012.

Although automobiles had already existed for decades, their adoption had been limited, and they were still mostly scarce and expensive. Automobiles were considered extreme luxury for the common man until the Model T. The Model T set 1908 as the historic year that the automobile became popular for the mass market. The first production Model T was produced on August 12, 1908 and left the factory on September 27, 1908, at the Piquette Plant in Detroit, Michigan. On May 26, 1927, Henry Ford watched the 15 millionth Model T Ford roll off the assembly line at his factory in Highland Park, Michigan.

There were several cars produced or prototyped by Henry Ford from the founding of the company in 1903 until the Model T was introduced. Although he started with the Model A, there were not 19 production models (A through T); some were only prototypes. The production model immediately before the Model T was the Model S, an upgraded version of the company’s largest success to that point, the Model N. The follow-up was the Ford Model A (rather than any Model U). The company publicity said this was because the new car was such a departure from the old that Henry wanted to start all over again with the letter A.

The Model T was Ford’s first automobile mass-produced on moving assembly lines with completely interchangeable parts, marketed to the middle class. Henry Ford said of the vehicle:

I will build a car for the great multitude. It will be large enough for the family, but small enough for the individual to run and care for. It will be constructed of the best materials, by the best men to be hired, after the simplest designs that modern engineering can devise. But it will be so low in price that no man making a good salary will be unable to own one – and enjoy with his family the blessing of hours of pleasure in God’s great open spaces.

Although credit for the development of the assembly line belongs to Ransom E. Olds with the first mass-produced automobile, the Oldsmobile Curved Dash, beginning in 1901, the tremendous advancements in the efficiency of the system over the life of the Model T can be credited almost entirely to the vision of Ford and his engineers.

Characteristics

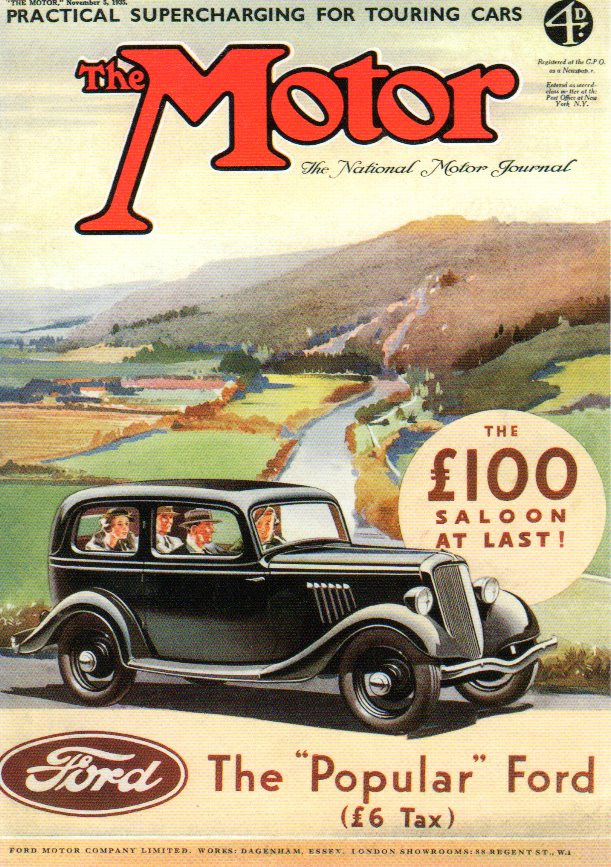

1908 Ford Model T advertisement

The Model T was designed by Childe Harold Wills, and Hungarian immigrants Joseph A. Galamb and Eugene Farkas. Henry Love, C. J. Smith, Gus Degner and Peter E. Martin were also part of the team. Production of the Model T began in the third quarter of 1908. Collectors today sometimes classify Model Ts by build years and refer to these as “model years“, thus labeling the first Model Ts as 1909 models. This is a retroactive classification scheme; the concept of model years as we conceive it today did not exist at the time. The nominal model designation was “Model T”, although design revisions did occur during the car’s two decades of production.

Engine

The Model T had a front-mounted 177-cubic-inch (2.9 L) inline four-cylinder engine, producing 20 hp (15 kW), for a top speed of 40–45 mph (64–72 km/h). According to Ford Motor Company, the Model T had fuel economy on the order of 13–21 mpg-US (16–25 mpg-imp; 18–11 L/100 km). The engine was capable of running on gasoline, kerosene, or ethanol, although the decreasing cost of gasoline and the later introduction of Prohibition made ethanol an impractical fuel for most users.

The ignition system used an unusual trembler coil system to drive the spark plugs, as used for stationary gas engines, rather than the expensive magnetos that were used on other cars. This ignition also made the Model T more flexible as to the quality or type of fuel it used. The need for a starting battery and also Ford’s use of an unusual AC alternator located inside the flywheel housing encouraged the adoption of electric lighting, rather than oil or acetylene lamps, but it also delayed the adoption of electric starting.

Transmission and drive train

The three pedal controls of the Model T

A driver’s controls in 1920

The Model T was a rear-wheel drive vehicle. Its transmission was a planetary gear type billed as “three speed”. In today’s terms it would be considered a two-speed, because one of the three speeds was reverse.

The Model T’s transmission was controlled with three foot pedals and a lever that was mounted to the road side of the driver’s seat. The throttle was controlled with a lever on the steering wheel. The left pedal was used to engage the gear. With the floor lever in either the mid position or fully forward and the pedal pressed and held forward the car entered low gear. When held in an intermediate position the car was in neutral. If the driver took his foot off the left pedal, the Model T entered high gear, but only when the lever was fully forward – in any other position the pedal would only move up as far as the central neutral position. This allowed the car to be held in neutral while the driver cranked the engine by hand. The car could thus cruise without the driver having to press any of the pedals. There was no separate clutch pedal.

When the car was in neutral, the middle pedal was used to engage reverse gear, and the right pedal operated the transmission brake – there were no separate brakes on the wheels. The floor lever also controlled the parking brake, which was activated by pulling the lever all the way back. This doubled as an emergency brake.

Although it was uncommon, the drive bands could fall out of adjustment, allowing the car to creep, particularly when cold, adding another hazard to attempting to start the car: a person cranking the engine could be forced backward while still holding the crank as the car crept forward, although it was nominally in neutral. As the car utilized a wet clutch, this condition could also occur in cold weather, where the thickened oil prevents the clutch discs from slipping freely. Power reached the differential through a single universal joint attached to a torque tube which drove the rear axle; some models (typically trucks, but available for cars as well) could be equipped with an optional two-speed Ruckstell rear axle shifted by a floor-mounted lever which provided an underdrive gear for easier hill climbing. All gears were vanadium steel running in an oil bath.

Transmission bands and linings

There were two main types of band lining material used:

- Cotton – Cotton woven linings were the original type fitted and specified by Ford. Generally, the cotton lining is “kinder” to the drum surface, with damage to the drum caused only by the retaining rivets scoring the drum surface. Although this in itself did not pose a problem, a dragging band resulting from improper adjustment caused overheating transmission and engine, diminished power, and—in the case of cotton linings—rapid destruction of the band lining.

- Wood – Wooden linings were originally offered as a “longer life” accessory part during the life of the Model T. They were a single piece of steam bent cottonwood fitted to the normal Model T Transmission band. These bands give a very different feel to the pedals, with much more of a “bite” feel. The sensation is of a definite “grip” of the drum and seemed to noticeably increase the feel, in particular of the brake drum.

Suspension and wheels

The suspension components of a Ford Model T. The coil-spring device is an aftermarket accessory, the “Hassler shock absorber”.

Model T suspension employed a transversely mounted semi-elliptical spring for each of the front and rear beam axles which allowed a great deal of wheel movement to cope with the dirt roads of the time.

The front axle was drop forged as a single piece of vanadium steel. Ford twisted many axles eight times and sent them to dealers to be put on display to demonstrate its superiority. The Model T did not have a modern service brake. The right foot pedal applied a band around a drum in the transmission, thus stopping the rear wheels from turning. The previously mentioned parking brake lever operated band brakes acting on the inside of the rear brake drums, which were an integral part of the rear wheel hubs. Optional brakes that acted on the outside of the brake drums were available from aftermarket suppliers.

Wheels were wooden artillery wheels, with steel welded-spoke wheels available in 1926 and 1927.

Tires were pneumatic clincher type, 30 in (76 cm) in diameter, 3.5 in (8.9 cm) wide in the rear, 3 in (7.5 cm) wide in the front. Clinchers needed much higher pressure than today’s tires, typically 60 psi (410 kPa), to prevent them from leaving the rim at speed. Horseshoe nails on the roads, together with the high pressure, made flat tires a common problem.

Balloon tires became available in 1925. They were 21 in × 4.5 in (53 cm × 11 cm) all around. Balloon tires were closer in design to today’s tires, with steel wires reinforcing the tire bead, making lower pressure possible – typically 35 psi (240 kPa) – giving a softer ride. The old nomenclature for tire size changed from measuring the outer diameter to measuring the rim diameter so 21 in (530 mm) (rim diameter) × 4.5 in (110 mm) (tire width) wheels has about the same outer diameter as 30 in (76 cm) clincher tires. All tires in this time period used an inner tube to hold the pressurized air; “tubeless” tires were not generally in use until much later.

Wheelbase was 100 inches (254 cm); while standard tread width was 56 in (142 cm), 60 in (152 cm) tread could be obtained on special order, “for Southern roads”, identical to the pre-Civil War track gauge for many railroads in the former Confederacy.

Colors

By 1918, half of all the cars in the US were Model Ts. However, it was a monolithic bloc; Ford wrote in his autobiography that in 1909 he told his management team that in the future “Any customer can have a car painted any color that he wants so long as it is black”.

However, in the first years of production from 1908 to 1913, the Model T was not available in black[24] but rather only grey, green, blue, and red. Green was available for the touring cars, town cars, coupes, and Landaulets. Grey was only available for the town cars, and red only for the touring cars. By 1912, all cars were being painted midnight blue with black fenders. It was only in 1914 that the “any color so long as it is black” policy was finally implemented. It is often stated that Ford suggested the use of black from 1914 to 1926 due to the cheap cost and durability of black paint. During the lifetime production of the Model T, over 30 different types of black paint were used on various parts of the car. These were formulated to satisfy the different means of applying the paint to the various parts, and had distinct drying times, depending on the part, paint, and method of drying.

Body

1925 Ford “New Model” T Tudor Sedan

Although Ford classified the Model T with a single letter designation throughout its entire life and made no distinction by model years, there were enough significant changes to the body over the production life that the car can be classified into five distinct generations. One of the most immediately visible and identifiable areas of change were in the hood and cowl areas although there were also many other changes made to the vehicle.

- 1909–1914 – T1 – Characterized by a nearly straight, five sided hood, with a flat top containing a center hinge and two side sloping sections containing the folding hinges. The firewall was flat from the windshield down with no distinct cowl.

- 1915–1916 – T2 – The hood design was nearly the same five sided design with the only obvious change being the addition of louvers to the vertical sides. There was a significant change to the cowl area with the windshield relocated significantly behind the firewall and joined with a compound contoured cowl panel.

- 1917–1923 – T3 – The hood design was changed to a tapered design with a curved top. the folding hinges were now located at the joint between the flat sides and the curved top. This is sometime referred to as the low hood to distinguish if from the later hoods. The back edge of the hood now met the front edge of the cowl panel so that no part of the flat firewall was visible outside of the hood. This design was used the longest and during the highest production years accounting for about half of the total number of Model T’s built.

- 1923–1925 – T4 – This change was made during the 1923 calendar year so models built earlier in the year have the older design while later vehicles have the newer design. The taper of the hood was increased and the rear section at the firewall is about an inch taller and several inches wider than the previous design. While this is a relatively minor change, the parts between the third and fourth generation are not interchangeable.

- 1926–1927 – T5 – This design change made the greatest difference in the appearance of the car. The hood was again enlarged with the cowl panel no longer a compound curve and blended much more with the line of the hood. The distance between the firewall and the windshield was also increased significantly. This style is sometimes referred to as the high hood.

The styling on the fifth generation was a preview for the following Model A but the two models are visually quite different as the body on the ‘A was much wider and had curved doors as opposed to the flat doors on the T.

Diverse applications

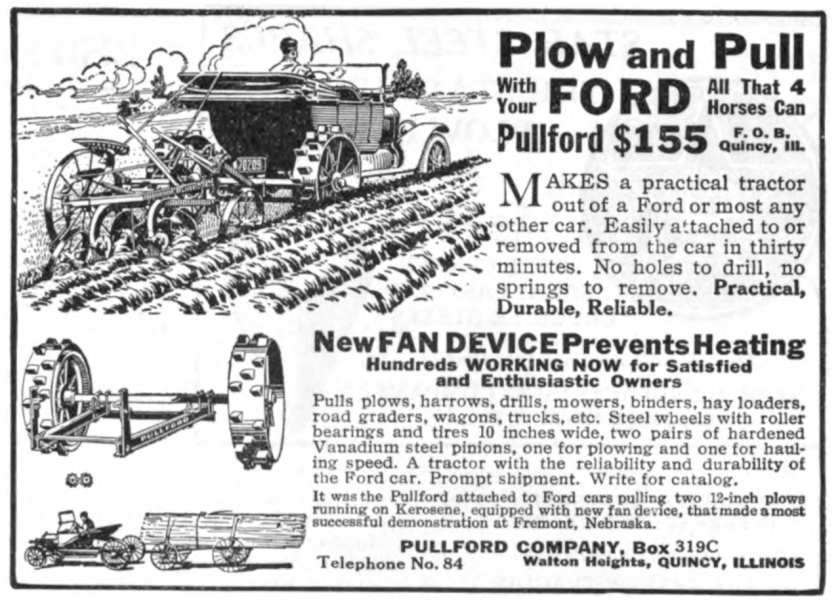

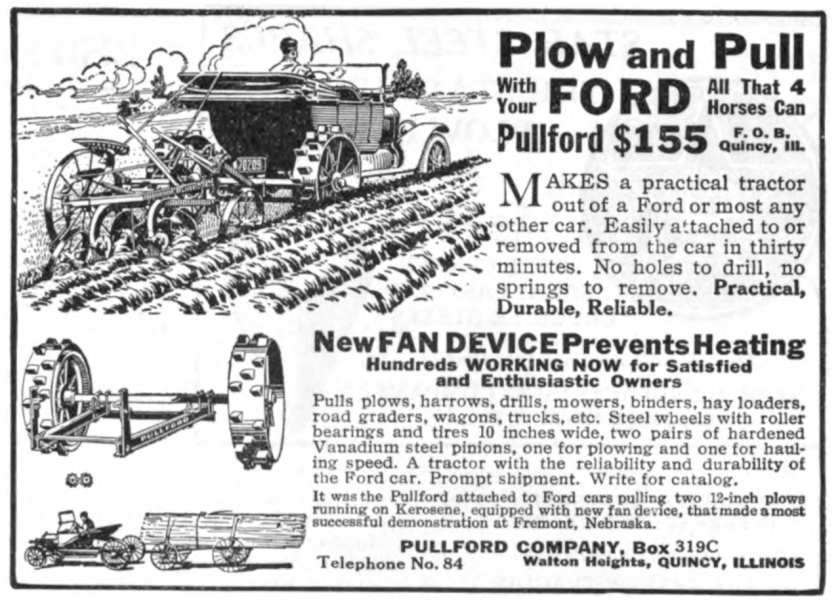

Pullford auto-to-tractor conversion advertisement, 1918

When the Model T was designed and introduced, the infrastructure of the world was quite different from today’s. Pavement was a rarity except for sidewalks and a few big-city streets. (The sense of the term “pavement” as equivalent with “sidewalk” comes from that era, when streets and roads were generally dirt and sidewalks were a paved way to walk along them.) Agriculture was the occupation of many people. Power tools were scarce outside factories, as were power sources for them; electrification, like pavement, was found usually only in larger towns. Rural electrification and motorized mechanization were embryonic in North America and Europe, and nonexistent elsewhere.

Henry Ford oversaw the requirements and design of the Model T based on the realities of that world. Consequently, the Model T was (intentionally) almost as much a tractor and portable engine as it was an automobile. It has always been well regarded for its all-terrain abilities and ruggedness. It could travel a rocky, muddy farm lane, ford a shallow stream, climb a steep hill, and be parked on the other side to have one of its wheels removed and a pulley fastened to the hub for a flat belt to drive a bucksaw, thresher, silo blower, conveyor for filling corn cribs or haylofts, baler, water pump (for wells, mines, or swampy farm fields), electrical generator, and countless other applications. One unique application of the Model T was shown in the October 1922 issue of Fordson Farmer magazine. It showed a minister who had transformed his Model T into a mobile church, complete with small organ.

During this era, entire automobiles (including thousands of Model Ts) were even hacked apart by their industrious owners and reconfigured into custom machinery permanently dedicated to a purpose, such as homemade tractors, ice saws, or many others. Dozens of aftermarket companies sold prefab kits to facilitate the T’s conversion from car to tractor. The Model T had been around for a decade before the Fordson tractor became available (1917–1918), and many Ts had been converted for field use. (For example, Harry Ferguson, later famous for his hitches and tractors, worked on Eros Model T tractor conversions before he worked with Fordsons and others.) During the next decade, Model T tractor conversion kits were harder to sell, as the Fordson and then the Farmall (1924), as well as other light and affordable tractors, served the farm market. But during the Depression(1930s), Model T tractor conversion kits had a resurgence, because by then used Model Ts and junkyard parts for them were plentiful and cheap.

Like many popular car engines of the era, the Model T engine was also used on home-built aircraft (such as the Pietenpol Sky Scout) and motorboats.

Many Model Ts were converted into vehicles which could travel across heavy snows with kits on the rear wheels (sometimes with an extra pair of rear-mounted wheels and two sets of continuous track to mount on the now-tandemed rear wheels, essentially making it a half-track) and skis replacing the front wheels. They were popular for rural mail delivery for a time. The common name for these conversions of cars and small trucks wassnowflyers. These vehicles were extremely popular in the northern reaches of Canada where factories were set up to produce them.

A number of companies built Model T–based railcars. In The Great Railway Bazaar, Paul Theroux mentions a rail journey in India on such a railcar. The New Zealand Railways Department‘s RM class included a few.

Production

Mass production

The knowledge and skills needed by a factory worker were reduced to 84 areas. When introduced, the T used the building methods typical at the time, assembly by hand, and production was small. Ford’s Piquette plant could not keep up with demand for the Model T, and only 11 cars were built there during the first full month of production. More and more machines were used to reduce the complexity within the 84 defined areas. In 1910, after assembling nearly 12,000 Model Ts, Henry Ford moved the company to the new Highland Park complex.

As a result, Ford’s cars came off the line in three-minute intervals, much faster than previous methods, reducing production time by a factor of eight (requiring 12.5 hours before, 93 minutes afterwards), while using less manpower. By 1914, the assembly process for the Model T had been so streamlined it took only 93 minutes to assemble a car. That year Ford produced more cars than all other automakers combined. The Model T was a great commercial success, and by the time Henry made his 10 millionth car, 50 percent of all cars in the world were Fords. It was so successful that Ford did not purchase any advertising between 1917 and 1923, instead it became so famous that people now considered it a norm; more than 15 million Model Ts were manufactured, reaching a rate of 9,000 to 10,000 cars a day in 1925, or 2 million annually, more than any other model of its day, at a price of just $260 (or about $3,230 in 2015 dollars). Model T production was finally surpassed by the Volkswagen Beetle on February 17, 1972.

Henry Ford’s ideological approach to Model T design was one of getting it right and then keeping it the same; he believed the Model T was all the car a person would, or could, ever need. As other companies offered comfort and styling advantages, at competitive prices, the Model T lost market share. Design changes were not as few as the public perceived, but the idea of an unchanging model was kept intact. Eventually, on May 26, 1927, Ford Motor Company ceased US production and began the changeovers required to produce the Model A. Some of the other Model T factories in the world continued a short while.

Model T engines continued to be produced until August 4, 1941. Almost 170,000 were built after car production stopped, as replacement engines were required to service already produced vehicles. Racers and enthusiasts, forerunners of modern hot rodders, used the Model T’s block to build popular and cheap racing engines, including Cragar, Navarro, and famously the Frontenacs (“Fronty Fords”) of the Chevrolet brothers, among many others.

The Model T employed some advanced technology, for example, its use of vanadium steel alloy. Its durability was phenomenal, and many Model Ts and their parts remain in running order nearly a century later. Although Henry Ford resisted some kinds of change, he always championed the advancement of materials engineering, and often mechanical engineering and industrial engineering.

In 2002, Ford built a final batch of six Model Ts as part of their 2003 centenary celebrations. These cars were assembled from remaining new components and other parts produced from the original drawings. The last of the six was used for publicity purposes in the UK.

Although Ford no longer manufactures parts for the Model T, many parts are still manufactured through private companies as replicas to service the thousands of Model Ts still in operation today. On May 26, 1927 Henry Ford and his son Edsel, drove the 15 millionth Model T out of the factory. This marked the famous automobile’s official last day of production at the main factory.

Price and Production

The assembly line system allowed Ford to sell his cars at a price lower than his competitors due to the efficiency of the system. As he continued to fine tune the system, he was able to keep reducing his costs. As his volume increased, he was able to also lower the prices due to fixed costs being spread over a larger number of vehicles. Other factors affected the price such a material costs and design changes.

The figures below are US production numbers compiled by R.E. Houston, Ford Production Department, August 3, 1927. The figures between 1909 and 1920 are for Ford’s fiscal year. From 1909 to 1913, the fiscal year was from October 1 to September 30 the following calendar year with the year number being the year it ended in. For the 1914 fiscal year, the year was October 1, 1913 through July 31, 1914. Starting in August 1914, and through the end of the Model T era, the fiscal year was August 1 through July 31. Beginning with January 1920 the figures are for the calendar year.

| Year |

Production |

Price for

Runabout |

Notes |

| 1909 |

10,666 |

$825 |

($21,650 in 2015) Touring car was $850 |

| 1910 |

19,050 |

$900 |

|

| 1911 |

34,858 |

$680 |

|

| 1912 |

68,773 |

$590 |

|

| 1913 |

170,211 |

$525 |

|

| 1914 |

202,667 |

$440 |

Fiscal year was only 10 months long due to change in end date

from Sep 30 to July 31 |

| 1915 |

308,162 |

$390 |

|

| 1916 |

501,462 |

$345 |

|

| 1917 |

735,020 |

$500 |

|

| 1918 |

664,076 |

$500 |

|

| 1919 |

498,342 |

$500 |

|

| 1920 |

941,042 |

$395 |

Production for fiscal year 1920, (August 1, 1919 through July 31, 1920)

Price was $550 in March but dropped by Sept |

| 1920 |

463,451 |

$395 |

Production for balance of calendar year, August 1 though Dec 31

Total ‘1920’ production (17 months) = 1,404,493 |

| 1921 |

971,610 |

$325 |

Price was $370 in June but dropped by Sept. |

| 1922 |

1,301,067 |

$319 |

|

| 1923 |

2,011,125 |

$364 |

|

| 1924 |

1,922,048 |

$265 |

|

| 1925 |

1,911,705 |

$260 |

($3,500 in 2015) Touring car was $290 |

| 1926 |

1,554,465 |

$360 |

|

| 1927 |

399,725 |

$360 |

Production ended before mid-year to allow retooling for the Model A |

Recycling

Henry Ford used wood scraps from the production of Model Ts to make charcoal. Originally named Ford Charcoal, the name was changed to Kingsford Charcoal after Ford’s brother-in-law E. G. Kingsford brokered the selection of the new charcoal plant site.

First global car

The Ford Model T was the first automobile built by various countries simultaneously since they were being produced in Walkerville, Canada and in Trafford Park, Greater Manchester, England starting in 1911 and were later assembled in Germany, Argentina, France, Spain, Denmark, Norway, Belgium, Brazil, Mexico, and Japan, as well as several locations throughout the US. Ford made use of the knock-down kit concept almost from the beginning of the company as freight cost had Ford assembling on the west coast of the US.

The Aeroford was an English automobile manufactured in Bayswater, London, from 1920 to 1925. It was a Model T with distinct hood and grille to make it appear to be a totally different design, what later would have been called badge engineering. The Aeroford sold from £288 in 1920, dropping to £168-214 by 1925. It was available as a two-seater, four-seater, or coupé.

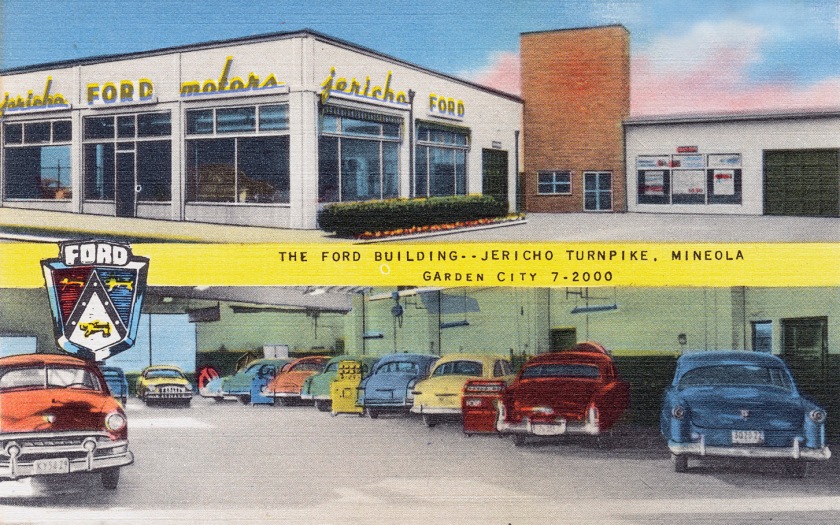

Advertising and marketing

Ford created a massive publicity machine in Detroit to ensure every newspaper carried stories and advertisements about the new product. Ford’s network of local dealers made the car ubiquitous in virtually every city in North America. As independent dealers, the franchises grew rich and publicized not just the Ford but the very concept of automobiling; local motor clubs sprang up to help new drivers and to explore the countryside. Ford was always eager to sell to farmers, who looked on the vehicle as a commercial device to help their business. Sales skyrocketed – several years posted 100% gains on the previous year.

Car clubs

1919 Ford Model T stakebed

Cars built before 1919 are classed as veteran cars and later models as vintage cars. Today, four main clubs exist to support the preservation and restoration of these cars: the Model T Ford Club International, the Model T Ford Club of America and the combined clubs of Australia. With many chapters of clubs around the world, the Model T Ford Club of Victoria has a membership with a considerable number of uniquely Australian cars. (Australia produced its own car bodies, and therefore many differences occurred between the Australian bodied tourers and the US/Canadian cars.) In the UK, the Model T Ford Register of Great Britain celebrated its 50th anniversary in 2010. Many steel Model T parts are still manufactured today, and even fiberglass replicas of their distinctive bodies are produced, which are popular for T-bucket style hot rods (as immortalized in the Jan and Dean surf music song “Bucket T”, which was later recorded by The Who). In 1949, more than twenty years after the end of production, 200,000 Model Ts were registered in the United States. In 2008, it was estimated that about 50,000 to 60,000 Ford Model T remain roadworthy.

In popular media

Someone should write an erudite essay on the moral, physical, and aesthetic effect of the Model T Ford on the American nation. Two generations of Americans knew more about the Ford coil than about the clitoris, about the planetary system of gears than the solar system of stars. With the Model T, part of the concept of private property disappeared. Pliers ceased to be privately owned and a tire iron belonged to the last man who had picked it up. Most of the babies of the period were conceived in Model T Fords and not a few were born in them. The theory of the Anglo Saxon home became so warped that it never quite recovered.

- In Aldous Huxley‘s Brave New World, where Henry Ford is regarded as a messianic figure, graveyard crosses have been truncated to T’s. Additionally, the calendar is converted to an “A.F.” system, wherein the first calendar year leads from the introduction of the Model T.

- The phrase to “go the way of the Tin Lizzie” is a colloquialism referring to the decline and elimination of a popular product, habit, belief or behavior as a now outdated historical relic which has been replaced by something new.

- The Tin Lizzie is mentioned (simply as “Lizzie”) in George and Ira Gershwin‘s song They All Laughed.

Gallery

| Model T Ford Automobile Chronology |

|

|

|

1908 Runabout – Note flat firewall

|

|

|

|

1915 Runabout – Note curved cowl panel

|

|

|

|

1917 Runabout – Note new curved hood matches cowl panel

|

|

|

|

1923 Runabout (early ’23 model)

|

|

|

|

1924 Touring – Note higher hood and slightly shorter cowl panel – late ’23 models were similar

|

|

|

|

1926 Runabout – Note higher hood and longer cowl panel

|

|

|

|

1927 Model A – Shown for comparison, note wider body and curved doors

|

|

In 1927, Ford introduced the Model A, the first car with safety glass in the windshield. Ford launched the first low priced V8 engine powered car in 1932.

The creation of a scientific laboratory in Dearborn, Michigan in 1951, doing unfettered basic research, lead to Ford’s unlikely involvement in superconductivity research. In 1964 Ford Research Labs made a key breakthrough with the invention of a superconducting quantum interference device or SQUID.

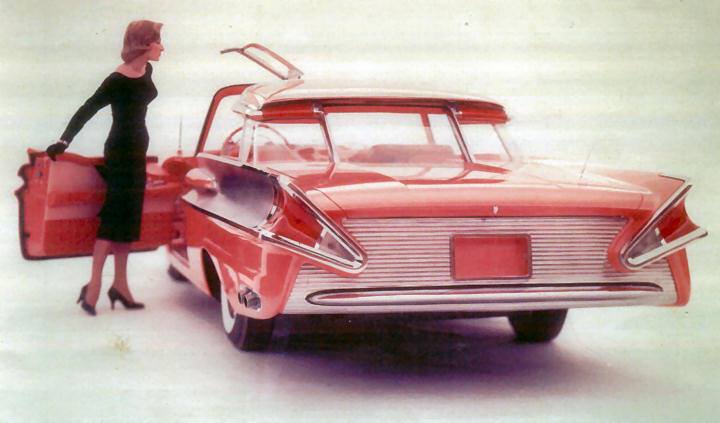

Ford offered the Lifeguard safety package from 1956, which included such innovations as a standard deep-dish steering wheel, optional front, and, for the first time in a car, rear seatbelts, and an optional padded dash. Ford introduced child-proof door locks into its products in 1957, and in the same year offered the first retractable hardtop on a mass-produced six-seater car. The Ford Mustang was introduced in 1964. In 1965 Ford introduced the seat belt reminder light.

With the 1980s, Ford introduced several highly successful vehicles around the world. During the 1980s, Ford began using the advertising slogan, “Have you driven a Ford, lately?” to introduce new customers to their brand and make their vehicles appear more modern. In 1990 and 1994 respectively, Ford also acquired Jaguar Cars and Aston Martin. During the mid- to late 1990s, Ford continued to sell large numbers of vehicles, in a booming American economy with a soaring stock market and low fuel prices.

With the dawn of the new century, legacy healthcare costs, higher fuel prices, and a faltering economy led to falling market shares, declining sales, and diminished profit margins. Most of the corporate profits came from financing consumer automobile loans through Ford Motor Credit Company.

21st century

By 2005, both Ford and GM‘s corporate bonds had been downgraded to junk status, as a result of high U.S. health care costs for an aging workforce, soaring gasoline prices, eroding market share, and an over dependence on declining SUV sales. Profit margins decreased on large vehicles due to increased “incentives” (in the form of rebates or low interest financing) to offset declining demand. In the latter half of 2005, Chairman Bill Ford asked newly appointed Ford Americas Division President Mark Fields to develop a plan to return the company to profitability. Fields previewed the Plan, named The Way Forward, at the December 7, 2005 board meeting of the company and it was unveiled to the public on January 23, 2006. “The Way Forward” included resizing the company to match market realities, dropping some unprofitable and inefficient models, consolidating production lines, closing 14 factories and cutting 30,000 jobs.

Ford moved to introduce a range of new vehicles, including “Crossover SUVs” built on unibody car platforms, rather than more body-on-frame chassis. In developing the hybrid electric powertrain technologies for the Ford Escape Hybrid SUV, Ford licensed similar Toyota hybrid technologies to avoid patent infringements. Ford announced that it will team up with electricity supply company Southern California Edison (SCE) to examine the future of plug-in hybrids in terms of how home and vehicle energy systems will work with the electrical grid. Under the multi-million-dollar, multi-year project, Ford will convert a demonstration fleet of Ford Escape Hybrids into plug-in hybrids, and SCE will evaluate how the vehicles might interact with the home and the utility’s electrical grid. Some of the vehicles will be evaluated “in typical customer settings”, according to Ford.

William Clay Ford Jr., great-grandson of Henry Ford (and better known by his nickname “Bill”), was appointed Executive Chairman in 1998, and also became Chief Executive Officer of the company in 2001, with the departure of Jacques Nasser, becoming the first member of the Ford family to head the company since the retirement of his uncle, Henry Ford II, in 1982. Upon the retirement of President and Chief Operation Officer Jim Padilla in April 2006, Bill Ford assumed his roles as well. Five months later, in September, Ford named Alan Mulally as President and CEO, with Ford continuing as Executive Chairman. In December 2006, the company raised its borrowing capacity to about $25 billion, placing substantially all corporate assets as collateral. Chairman Bill Ford has stated that “bankruptcy is not an option”. Ford and the United Auto Workers, representing approximately 46,000 hourly workers in North America, agreed to a historic contract settlement in November 2007 giving the company a substantial break in terms of its ongoing retiree health care costs and other economic issues. The agreement included the establishment of a company-funded, independently run Voluntary Employee Beneficiary Association (VEBA) trust to shift the burden of retiree health care from the company’s books, thereby improving its balance sheet. This arrangement took effect on January 1, 2010. As a sign of its currently strong cash position, Ford contributed its entire current liability (estimated at approximately US$5.5 billion as of December 31, 2009) to the VEBA in cash, and also pre-paid US$500 million of its future liabilities to the fund. The agreement also gives hourly workers the job security they were seeking by having the company commit to substantial investments in most of its factories.

The automaker reported the largest annual loss in company history in 2006 of $12.7 billion, and estimated that it would not return to profitability until 2009. However, Ford surprised Wall Street in the second quarter of 2007 by posting a $750 million profit. Despite the gains, the company finished the year with a $2.7 billion loss, largely attributed to finance restructuring at Volvo.

On June 2, 2008, Ford sold its Jaguar and Land Rover operations to Tata Motors for $2.3 billion.

During Congressional hearings held in November 2008 at Washington D.C., and in a show of support, Ford’s Alan Mulally stated that “We at Ford are hopeful that we have enough liquidity. But we also must prepare ourselves for the prospect of further deteriorating economic conditions”. Mulally went on to state that “The collapse of one of our competitors would have a severe impact on Ford” and that Ford Motor Company’s supports both Chrysler and General Motors in their search for government bridge loans in the face of conditions caused by the 2008 financial crisis. Together, the three companies presented action plans for the sustainability of the industry. Mulally stated that “In addition to our plan, we are also here today to request support for the industry. In the near-term, Ford does not require access to a government bridge loan. However, we request a credit line of $9 billion as a critical backstop or safeguard against worsening conditions as we drive transformational change in our company” GM and Chrysler received government loans and financing through T.A.R.P. legislation funding provisions.

On December 19, the cost of credit default swaps to insure the debt of Ford was 68 percent the sum insured for five years in addition to annual payments of 5 percent. That meant $6.8 million paid upfront to insure $10 million in debt, in addition to payments of $500,000 per year. In January 2009, Ford reported a $14.6 billion loss in the preceding year, a record for the company. The company retained sufficient liquidity to fund its operations. Through April 2009, Ford’s strategy of debt for equity exchanges erased $9.9 billion in liabilities (28% of its total) in order to leverage its cash position. These actions yielded Ford a $2.7 billion profit in fiscal year 2009, the company’s first full-year profit in four years.

In 2012, Ford’s corporate bonds were upgraded from junk to investment grade again, citing sustainable, lasting improvements.

On October 29, 2012, Ford announced the sale of its climate control components business, its last remaining automotive components operation, to Detroit Thermal Systems LLC for an undisclosed price.

On November 1, 2012, Ford announced that CEO Alan Mulally will stay with the company until 2014. Ford also named Mark Fields, the president of operations in Americas, as its new chief operating officer Ford’s CEO Mulally was paid a compensation of over $174 million in his previous seven years at Ford since 2006. The generous amount has been a sore point for some workers of the company.

Logo evolution

Corporate affairs

Executive management

Members of the Ford board as of July 2014 are: Richard A. Gephardt, Stephen Butler, Ellen Marram, Kimberly Casiano, Mark Fields (President and CEO), Edsel Ford II, Homer Neal, William Clay Ford Jr. (Executive Chairman), Anthony F. Earley, Jr., James P. Hackett, John L. Thornton, James H. Hance, Jr., William W. Helman IV, Jon M. Huntsman, Jr., John C. Lechleiter and Gerald L. Shaheen.

Financial results

In 2010, Ford earned a net profit of $6.6 billion and reduced its debt from $33.6 billion to $14.5 billion lowering interest payments by $1 billion following its 2009 net profit of $2.7 billion. In the U.S., the F-Series was the best-selling vehicle for 2010. Ford sold 528,349 F-Series trucks during the year, a 27.7% increase over 2009, out of a total sales of 1.9 million vehicles, or every one out of four vehicles Ford sold. Trucks sales accounts for a big slice of Ford’s profits, according to USA Today. Ford’s realignment also included the sale of its wholly owned subsidiary, Hertz Rent-a-Car to a private equity group for $15 billion in cash and debt acquisition. The sale was completed on December 22, 2005. A 50–50 joint venture with Mahindra & Mahindra of India, called Mahindra Ford India, Limited (MIFL), ended with Ford buying out Mahindra’s remaining stake in the company in 2005. Ford had previously upped its stake to 72% in 1998.

Operations

Ford has manufacturing operations worldwide, including in the United States, Canada, Mexico, China, the United Kingdom, Germany, Turkey, Brazil, Argentina, Australia and South Africa. Ford also has a cooperative agreement with Russian automaker GAZ.

North America

In the first five months of 2010, auto sales in the U.S. rose to 4.6 million cars and light trucks, an increase of 17% from a year earlier. The rise was mainly caused by the return of commercial customers that had all but stopped buying in 2009 during the recession. Sales to individual customers at dealerships have increased 13%, while fleet sales have jumped 32%. Ford reported that 37% of its sales in May came from fleet sales when it announced its sales for the month increased 23%. In the first seven months of 2010, vehicle sales of Ford increased 24%, including retail and fleet sales. Fleet sales of Ford for the same period rose 35% to 386,000 units while retail sales increase 19%. Fleet sales account for 39 percent of Chrysler’s sales and 31 percent for GM’s.

Europe

Main article:

Ford of EuropeAt first, Ford in Germany and Ford in Britain built different models from one another until the late 1960s, with the Ford Escort and then the Ford Capri being common to both companies. Later on, the Ford Taunus and Ford Cortina became identical, produced in left hand drive and right hand drive respectively. Rationalisation of model ranges meant that production of many models in the UK switched to elsewhere in Europe, including Belgium and Spain as well as Germany. The Ford Sierra replaced the Taunus and Cortina in 1982, drawing criticism for its radical aerodynamic styling, which was soon given nicknames such as “Jellymould” and “The Salesman’s Spaceship.”

Increasingly, the Ford Motor Company has looked to Ford of Europe for its “world cars”, such as the Mondeo, Focus, and Fiesta, although sales of European-sourced Fords in the U.S. have been disappointing. The Focus has been one exception to this, which has become America’s best selling compact car since its launch in 2000.

In February 2002, Ford ended car production in the UK. It was the first time in 90 years that Ford cars had not been made in Britain, although production of the Transit van continued at the company’s Southampton facility until mid-2013, engines at Bridgend and Dagenham, and transmissions at Halewood. Development of European Ford is broadly split between Dunton in Essex (powertrain, Fiesta/Ka, and commercial vehicles) and Cologne (body, chassis, electrical, Focus, Mondeo) in Germany. Ford also produced the Thames range of commercial vehicles, although the use of this brand name was discontinued circa 1965. Elsewhere in continental Europe, Ford assembles the Mondeo range in Genk (Belgium), Fiesta in Valencia (Spain) and Cologne (Germany), Ka in Valencia (Spain), Focus in Valencia (Spain), Saarlouis (Germany) and Vsevolozhsk (Russia). Transit production is in Kocaeli (Turkey), Southampton (UK), and Transit Connect in Kocaeli (Turkey).

Ford also owns a joint-venture production plant in Turkey. Ford Otosan, established in the 1970s, manufactures the Transit Connect compact panel van as well as the “Jumbo” and long-wheelbase versions of the full-size Transit. This new production facility was set up near Kocaeli in 2002, and its opening marked the end of Transit assembly in Genk.

Another joint venture plant near Setúbal in Portugal, set up in collaboration with Volkswagen, formerly assembled the Galaxy people-carrier as well as its sister ships, the VW Sharan and SEAT Alhambra. With the introduction of the third generation of the Galaxy, Ford has moved the production of the people-carrier to the Genk plant, with Volkswagen taking over sole ownership of the Setúbal facility.

In 2008, Ford acquired a majority stake in Automobile Craiova, Romania. Starting 2009, the Ford Transit Connect was Ford’s first model produced in Craiova, followed, in 2012, by low-capacity car engines and a new small class car, the B-Max.

Ford Europe has broken new ground with a number of relatively futuristic car launches over the last 50 years.

Its 1959 Anglia two-door saloon was one of the most quirky-looking small family cars in Europe at the time of its launch, but buyers soon became accustomed to its looks and it was hugely popular with British buyers in particular. It was still selling well when replaced by the more practical Escort in 1967.

The third incarnation of the Ford Escort was launched in 1980 and marked the company’s move from rear-wheel drive saloons to front-wheel drive hatchbacks in the small family car sector.

The fourth generation Escort was produced from 1990 until 2000, although its successor – the Focus – had been on sale since 1998. On its launch, the Focus was arguably the most dramatic-looking and fine-handling small family cars on sale, and sold in huge volumes right up to the launch of the next generation Focus at the end of 2004.

The 1982 Ford Sierra – replacement for the long-running and massively popular Cortina and Taunus models – was a style-setter at the time of its launch. Its ultramodern aerodynamic design was a world away from a boxy, sharp-edged Cortina, and it was massively popular just about everywhere it was sold. A series of updates kept it looking relatively fresh until it was replaced by the front-wheel drive Mondeo at the start of 1993.

The rise in popularity of small cars during the 1970s saw Ford enter the mini-car market in 1976 with its Fiesta hatchback. Most of its production was concentrated at Valencia in Spain, and the Fiesta sold in huge figures from the very start. An update in 1983 and the launch of an all-new model in 1989 strengthened its position in the small car market.

On October 24, 2012, Ford announced that it would be closing its Genk assembly plant in eastern Belgium by the end of 2014.

Oceania

Ford FG Falcon (Australia)

In Australia and New Zealand, the popular Ford Falcon has long been considered the average family car and is considerably larger than the Mondeo, Ford’s largest car sold in Europe. Between 1960 and 1972, the Falcon was based on a U.S. model of the same name, but since then has been entirely designed and manufactured in Australia, occasionally being manufactured in New Zealand. Like its General Motors rival, the Holden Commodore, the Falcon uses a rear wheel drive layout. High performance variants of the Falcon running locally built engines produce up to 362 hp (270 kW). A ute (short for “utility”, known in the US as pickup truck) version is also available with the same range of drivetrains. In addition, Ford Australia sells highly tuned limited-production Falcon sedans and utes through its performance car division, Ford Performance Vehicles.

In Australia, the Commodore and Falcon have traditionally outsold all other cars and comprise over 20% of the new car market. In New Zealand, Ford was second in market share in the first eight months of 2006 with 14.4 per cent. More recently Ford has axed its Falcon-based LWB variant of its lineup– the Fairlane and LTD ranges, and announced that their Geelong engine manufacturing plant may be shut down from 2013. They have also announced local manufacturing of the Focus small car starting from 2011.

In Australia, the Laser was one of Ford Australia‘s most successful models, and was manufactured in Ford’s Homebush plant from 1981 until the plant’s closure in September 1994. It outsold the Mazda 323, despite being almost identical to it, because the Laser was manufactured in Australia and Ford was perceived as a local brand.

In New Zealand, the Ford Laser and Telstar were assembled alongside the Mazda 323 and 626 until 1997, at the Vehicle Assemblers of New Zealand (VANZ) plant in Wiri, Auckland. The Sierra wagon was also assembled in New Zealand, owing to the popularity of station wagons in that market.

The scheduled closure of Ford’s Australian manufacturing base in 2016 was confirmed in late May 2013. Headquartered in the Victorian suburb of Broadmeadows, the company had registered losses worth AU$600 million over the five years prior to the announcement. It was noted that the corporate fleet and government sales that account for two-thirds of large, local car sales in Australia are insufficient to keep Ford’s products profitable and viable in Australia. The decision will affect 1200 Ford workers—over 600 employees in Geelong and more than 500 in Broadmeadows—who will lose their jobs by October 2016.

East and Southeast Asia

Ford formed its first passenger-vehicle joint venture in China in 2001, six years behind GM and more than a decade after VW. It has spent as of 2013 $4.9 billion to expand its lineup and double production capacity in China to 600,000 vehicles. This includes Ford’s largest-ever factory complex in the southwestern city of Chongqing. Ford had 2.5 percent of the Chinese market in 2013, while VW controlled 14.5 percent and GM had 15.6 percent, according to consultant LMC Automotive. GM outsells Ford in China by more than six-to-one.

The Ford stamping plant in Geelong, Australia

With the acquisition of a stake in Japanese manufacturer Mazda in 1979, Ford began selling Mazda’s Familia and Capella (also known as the 323 and 626) as the Ford Laser and Telstar, replacing the European-sourced Escort and Cortina. Through its relationship with Mazda, Ford also acquired a stake in South Korean manufacturer Kia, which built the (Mazda-based) Ford Festiva from 1988–1993, and the Ford Aspire from 1994–1997 for export to the United States, but later sold their interest to Hyundai (which also manufactured the Ford Cortina until the 1980s). Kia continued to market the Aspire as the Kia Avella, later replaced by the Rio and once again sold in the US.

Ford’s presence in Asia has traditionally been much smaller, confined to Malaysia, Singapore, Hong Kong, the Philippines, and Taiwan, where Ford has had a joint venture with Lio Ho since the 1970s. Ford began assembly of cars in Thailand in 1960, but withdrew from the country in 1976, and did not return until 1995, when it formed a joint venture with Mazda called Auto Alliance. Now in Bo-win Sub District, Sriracha District of the Chonburi it is located The Ford Motor Company (Thailand) Limited, making passenger automobiles. The factory built in 1941 in Singapore was shortly taken over by the Japanese during the war and was the site of a surrender of the British to the Japanese, at the factory site which is now a national monument in Singapore.

On April 30, 2013, Ford Motor Co. launched their car and truck line in Myanmar. Previously, heavy importation taxes have stifled imported car purchases in Myanmar, but due to currency reform, lifting of previous import restrictions, and the abolishment of shadow currency, Myanmar’s car market has grown in demand.

Ford of Japan

Ford established a manufacturing facility in the port city of Yokohama in February 1925, where Model T vehicles were assembled using imported knock-down kits. The factory subsequently produced 10,000 Model A’s up to 1936. Production ceased in 1940 as a result of political tensions between Japan and the United States.

After World War II, Ford did not have a presence in Japan, as the Ford facility was appropriated by the Japanese Government until 1958, when property was returned as a possession of the Ford Motor Company and became a research and development location for Ford partner Mazda. In 1979, Ford acquired a 24.5% ownership stake in Mazda, and in 1982 Ford and Mazda jointly established a sales channel to sell Ford products in Japan, including vehicles manufactured in North America, at a dealership called Autorama(Japanese). The Autorama sales channel was renamed Ford Sales of Japan in 1997.

Vehicles sold at Autorama locations were the North American assembled Ford Explorer, Probe (1989–1998), Mustang, Taurus (1989–1997), Thunderbird (1990–1993), Lincoln Continental, and Lincoln LS. Ford products manufactured in Europe that were sold in Japan were the Ford Mondeo, Ka, Focus, Focus C-MAX, Fiesta, and the Galaxy. Mazda manufactured Ford vehicles in Japan and sold them as Fords at the Autorama locations. They were the Ford Telstar (Mazda Capella), Laser, Festiva, Festiva Mini Wagon,Ixion (Mazda Premacy), Freda (Mazda Bondo Friendee), Spectron (Mazda Bongo), and commercial trucks J80 and the J100 (Mazda Bongo truck).

Ford increased its shareholding in Mazda to 33.4% in 1996. Ford currently sells a small range of vehicles in Japan; as of October 2010, the Ford Mustang, Escape, Explorer (and Explorer truck), Ford Kuga, Lincoln Navigator and Lincoln MKX were available in Japan. Ford maintains a regional office in Minato, Tokyo, Japan.

South and West Asia

Ford India began production in 1998 at Chennai, Tamil Nadu, with its Ford Escort model, which was later replaced by locally produced Ford Ikon in 2001. It has since added Fusion, Fiesta, Mondeo and Endeavour to its product line.

On March 9, 2010, Ford Motor Co. launched its first made-for-India compact car. Starting at 349,900 ($7,690), the Figo is Ford’s first car designed and priced for the mass Indian market. On July 28, 2011, Ford India signed a memorandum of understanding (MoU) with the State of Gujarat for the construction of an assembly and engine plant in Sanand, and planned to invest approximately US$1 billion on a 460-acre site.

Ford’s market presence in the Middle East has traditionally been small, partly due to previous Arab boycotts of companies dealing with Israel. Ford and Lincoln vehicles are currently marketed in ten countries in the region. Saudi Arabia, Kuwait, and the UAE are the biggest markets. Ford also established itself in Egypt in 1926, but faced an uphill battle during the 1950s due to the hostile nationalist business environment. Ford’s distributor in Saudi Arabia announced in February 2003 that it had sold 100,000 Ford and Lincoln vehicles since commencing sales in November 1986. Half of the Ford/Lincoln vehicles sold in that country were Ford Crown Victorias. In 2004, Ford sold 30,000 units in the region, falling far short of General Motors‘ 88,852 units and Nissan Motors‘ 75,000 units.

South America

During much of the 20th century, Ford faced protectionist government measures in South America, with the result that it built different models in different countries, without particular regard to rationalization or economy of scale inherent to producing and sharing similar vehicles between the nations. In many cases, new vehicles in a country were based on those of the other manufacturers it had entered into production agreements with, or whose factories it had acquired. For example, the Corcel and Del Rey in Brazil were originally based on Renault vehicles.

In 1987, Ford of Brasil and Ford of Argentina merged their operations with the Brazilian and Argentinan operations of Volkswagen Group, forming a new joint-venture company called Autolatina with a shared model range. Sales figures and profitability were disappointing, and Autolatina was dissolved in 1995. With the advent of Mercosur, the regional common market, Ford was finally able to rationalize its product line-ups in those countries. Consequently, the Ford Fiesta and Ford EcoSport are only built in Brazil, and the Ford Focus only built in Argentina, with each plant exporting in large volumes to the neighboring countries. Models like the Ford Mondeo from Europe could now be imported completely built up. Ford of Brazil produces a pick-up truck version of the Fiesta, the Courier, which is also produced in South Africa as the Ford Bantam in right hand drive versions.

Africa

In Africa, Ford’s market presence has traditionally been strongest in South Africa and neighbouring countries, with only trucks being sold elsewhere on the continent. Ford in South Africa began by importing kits from Canada to be assembled at its Port Elizabeth facility. Later Ford sourced its models from the UK and Australia, with local versions of the Ford Cortina including the XR6, with a 3.0 V6 engine, and a Cortina-based ‘bakkie’ or pick-up, which was exported to the UK. In the mid-1980s Ford merged with a rival company, owned by Anglo American, to form the South African Motor Corporation (Samcor).

Following international condemnation of apartheid, Ford divested from South Africa in 1988, and sold its stake in Samcor, although it licensed the use of its brand name to the company. Samcor began to assemble Mazdas as well, which affected its product line-up, and saw the European Fords like the Escort and Sierra replaced by the Mazda-based Laser and Telstar. Ford bought a 45 per cent stake in Samcor following the demise of apartheid in 1994, and this later became, once again, a wholly owned subsidiary, the Ford Motor Company of Southern Africa. Ford now sells a local sedan version of the Fiesta (also built in India and Mexico), and the Focus. The Falcon model from Australia was also sold in South Africa, but was dropped in 2003, while the Mondeo, after briefly being assembled locally, was dropped in 2005.

Products and services

Automobiles

Ford Motor Company sells a broad range of automobiles under the Ford marque worldwide, and an additional range of luxury automobiles under the Lincoln marque in the United States. The company has sold vehicles under a number of other marques during its history. The Mercury brand was introduced by Ford in 1939, continuing in production until 2011 when poor sales led to its discontinuation. In 1958, Ford introduced the Edsel brand, but poor sales led to its discontinuation in 1960. In 1985, the Merkur brand was introduced in the United States to market products produced by Ford of Europe; it was discontinued in 1989.

Ford acquired the British sports car maker Aston Martin in 1989, later selling it on March 12, 2007, although retaining an 8% stake. Ford purchased Volvo Cars of Sweden in 1999, selling it to Zhejiang Geely Holding Group in 2010. In November 2008, it reduced its 33.4% controlling interest in Mazda of Japan to a 13.4% non-controlling interest. On November 18, 2010, Ford reduced their stake further to just 3%, citing the reduction of ownership would allow greater flexibility to pursue growth in emerging markets. Ford and Mazda remain strategic partners through exchanges of technological information and joint ventures, including an American joint venture plant in Flat Rock, Michigan called Auto Alliance. Ford sold the United Kingdom-based Jaguar and Land Rover companies and brands to Tata Motors of India in March 2008.

| Marque |

Country of origin |

Years used/owned |

Markets |

| Ford |

United States |

1903–Present |

Global |

| Lincoln |

United States |

1922–Present |

North America, Middle East |

| Mercury |

United States |

1939 – 2011 |

North America, Middle East |

| Edsel |

United States |

1958 – 1960 |

North America |

| Merkur |

United States |

1985 – 1989 |

North America |

| Jaguar |

United Kingdom |

1989 – 2008 |

Global |

| Aston Martin |

United Kingdom |

1989 – 2007 |

Global |

| Volvo |

Sweden |

1999 – 2010 |

Global |

| Land Rover |

United Kingdom |

2000 – 2008 |

Global |

| Mazda |

Japan |

1996 – 2010 |

Global |

| FPV |

Australia |

2002 – 2014 |

Australia |

| Troller |

Brazil |

2007–Present |

Brazil |

Trucks

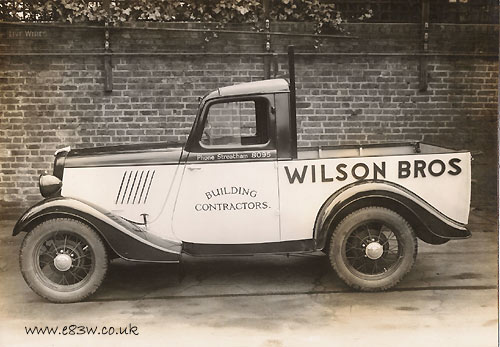

An advert for the 1939 Ford V-8 pick-up truck

An advert for the 1961 Ford H-Series truck

Ford has produced trucks since 1908, beginning with the Ford Model TT, followed by the Model AA, and the Model BB. Countries where Ford commercial vehicles are or were formerly produced include Argentina, Australia, Brazil, Canada (also badged as Mercury), France, Germany, India, Netherlands, Philippines, Spain (badged Ebro too), Turkey, UK (badged also Fordson and Thames) and USA.

From the 1940s to late 1970s Ford’s Ford F-Series were used as the base for light trucks for the North American market.

Most of these ventures are now extinct. The European one that lasted longest was the lorries arm of Ford of Britain, which became part of the Iveco group in 1986. Ford had a minority share in the new company and Iveco took over sales and production of the Ford Cargo range. Ford’s last significant European truck models were the Transcontinental and the Cargo.

In the United States, Ford’s heavy trucks division (Classes 7 and 8) was sold in 1997 to Freightliner Trucks, which rebranded the lineup as Sterling. Freightliner is in the process of discontinuing this line.

Line of heavy trucks made by Ford for the North American market:

Ford continues to manufacture medium duty trucks under the F-650 and F-750 badges. In 2001, the company entered into a joint venture with Navistar International to produce medium and heavy duty commercial trucks. The first new model from the new corporation, known as Blue Diamond Truck Company LLC, was the 2006 model year LCF, the first Ford branded cab-over-engine design in the United States since Freightliner’s acquisition of the Cargo in the mid-1990s. The LCF was discontinued in 2009 and Ford’s 2011 medium and heavy-duty commercial offerings are limited to the two F-Series.

In 1999 the end of the F800 indicated Ford was no longer producing in any F-series heavy truck chassis.

In Europe, Ford manufactures the Ford Transit jumbo van which is classed as a Large Goods Vehicle and has a payload of up to 2,265 kg, there are options of a panel van, pickup or chassis cab. The Ford Transit is also available as a light van called the Ford Transit Connect and the Ford Ranger pickup is available.

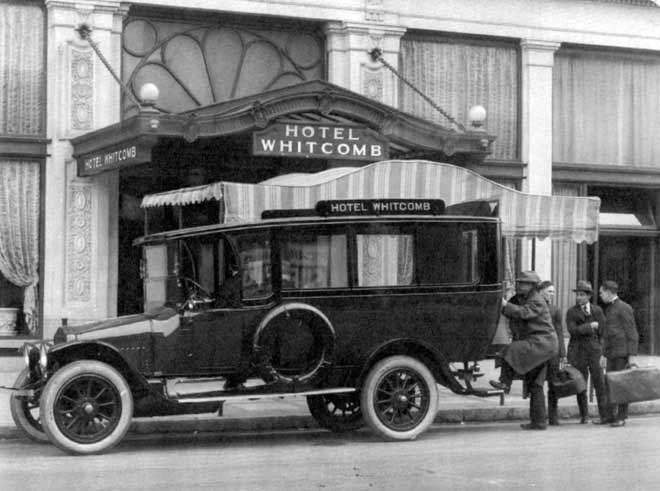

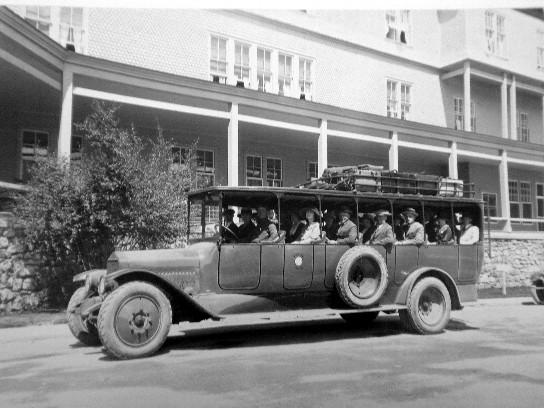

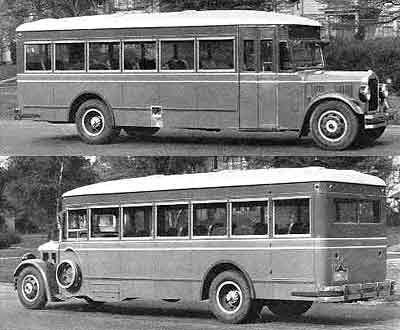

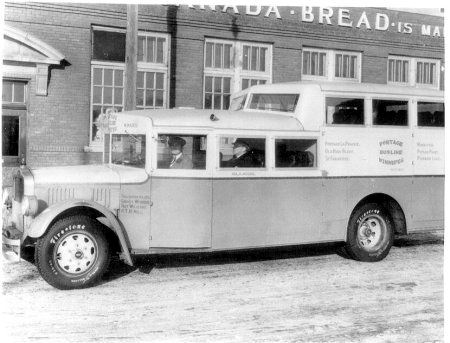

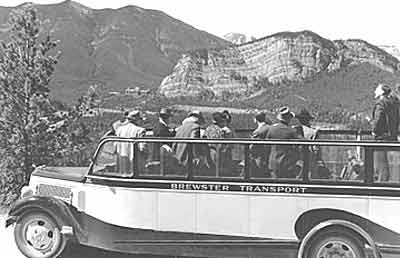

Buses

Ford manufactured complete buses in the company’s early history, but today the role of the company has changed to that of a second stage manufacturer. In North America, the E-Series is still used as a chassis for small school buses and the F-650 is used in commercial bus markets. In the 1980s and 1990s, the medium-duty B700 was a popular chassis used by school bus body manufacturers including Thomas Built, Ward and Blue Bird, but Ford lost its market share due to industry contraction and agreements between body manufacturers. Older bus models included:

Prior to 1936, Ford buses were based on truck bodies:

- Model B – 1930s

- Model T – 1920s

- F-105 school bus

In 1936, Ford introduced the Ford Transit Bus, a series of small transit buses with bodies built by a second party. Originally a front-engine design, it was modified to a rear-engine design in 1939. About 1,000 to 1,200 of the original design were built, and around 12,500 of the rear-engine design, which was in production until 1947 (rebranded as the Universal Bus in 1946).

Rear-engine Transit Bus chassis model numbers:

- 09-B/19-B City transit bus – 1939–1941

- 19-B/29-B City transit bus – 1941–1942

- 49-B/79-B City transit bus – 1944–1947

- 69-B City transit bus – 1946–1947

- 29-B City transit bus – 1946–1947

- 72-T transit bus – 1944–1945

After 1946 the Transit City bus was sold as the Universal Bus with the roof changed from fabric/wood to all-metal:

- 79-B Universal transit bus – 1946–1947

Succeeding the Ford Transit Bus was the Ford 8M buses:

- 8MB transit bus – with Wayne Works 1948–?

Following World War II and from 1950s onwards Ford lost out to General Motors. This led to the end of transit buses for Ford in North America.

- B500 or B-series – 1950-1990s based on Ford F-series truck chassis used by school bus body manufacturers

In Europe, Ford manufactures the Ford Transit Minibus which is classed in Europe as a Passenger Carrying Vehicle and there are options of 12, 15 or 17 seaters. In the past European models included:

- EM

- N-138

- D series buses (Australia)

Tractors

The “Henry Ford and Son Company” began making Fordson tractors in Henry’s hometown of Springwells (later part of Dearborn), Michigan from 1907 to 1928, from 1919 to 1932, at Cork, Ireland, and 1933–1964 at Dagenham, England, later transferred to Basildon. They were also produced in Leningrad beginning in 1924.

In 1986, Ford expanded its tractor business when it purchased the Sperry-New Holland skid-steer loader and hay baler, hay tools and implement company from Sperry Corporation and formed Ford-New Holland which bought out Versatile tractors in 1988. This company was bought by Fiat in 1993 and the name changed from Ford New Holland to New Holland. New Holland is now part of CNH Global.

Financial services

Ford offers automotive finance through Ford Motor Credit Company.

Automotive components

Ford’s FoMoCo parts division sells aftermarket parts under the Motorcraft brand name. It has spun off its parts division under the name Visteon.

Motorsport

Main article:

Ford RacingAlong with Shelby and Chevrolet, Ford is one of only three American constructors to win titles on the international scene at the FIA World Championships. As a constructor, Ford won the World Sportscar Championship three times in 1966, 1967 and 1968, and theWorld Rally Championship three times in 1979, 2006 and 2007.

Stock car racing

Ford is one of three manufacturers in NASCAR‘s three major series: Sprint Cup Series, Xfinity Series and Camping World Truck Series. Major teams include Roush Fenway Racing, Team Penske, and Richard Petty Motorsports. Ford is represented by the mid-size Fusion in the Sprint Cup, the Mustang in the Nationwide Series, and by the F-150 in the Camping World Truck Series. Some of the most successful NASCAR Fords were the aerodynamic fastback Ford Torino, Ford Torino Talladega, Mercury Cyclone Spoiler II, and Mercury Montegos, and the aero-era Ford Thunderbirds. The Ford nameplate has won eight manufacturer’s championships in Sprint Cup, while Mercury has won one. In the Sprint Cup Series, Ford earned its 1,000th victory in the 2013 Quicken Loans 400. The Ford Fusion is also used in the ARCA Remax Series. Ford had last won a drivers’ championship in the Cup Series with Kurt Busch in 2004.

Formula One

Ford was heavily involved in Formula One for many years, and supplied engines to a large number of teams from 1967 until 2004. These engines were designed and manufactured by Cosworth, the racing division that was owned by Ford from 1998 to 2004. Ford-badged engines won 176 Grands Prix between 1967 and 2003 for teams such as Team Lotus and McLaren. Ford entered Formula One as a constructor in 2000 under the Jaguar Racing name, after buying the Stewart Grand Prix team which had been its primary ‘works’ team in the series since 1997. Jaguar achieved little success in Formula One, and after a turbulent five seasons, Ford withdrew from the category after the 2004 season, selling both Jaguar Racing (which became Red Bull Racing) and Cosworth (to Gerald Forsythe and Kevin Kalkhoven).

Rally

Ford has a long history in rallying and has been active in the World Rally Championship since the beginning of the world championship, the 1973 season. Ford took the 1979 manufacturers’ title with Hannu Mikkola, Björn Waldegård and Ari Vatanen driving the Ford Escort RS1800. In the Group B era, Ford achieved success with Ford RS200. Since the 1999 season, Ford has used various versions of the Ford Focus WRC to much success. In the 2006 season, BP-Ford World Rally Team secured Ford its second manufacturers’ title, with the Focus RS WRC 06 built by M-Sport and driven by “Flying Finns” Marcus Grönholm and Mikko Hirvonen. Continuing with Grönholm and Hirvonen, Ford successfully defended the manufacturers’ world championship in the 2007 season. Ford is the only manufacturer to score in the points for 92 consecutive races; since the 2002 season opener Monte Carlo Rally.

Sports cars

Ford sports cars have been visible in the world of sports car racing since 1964. Most notably the GT40 won the 24 Hours of Le Mans four times in the 1960s and is the only American car to ever win overall at this prestigious event. Ford also won the 1968 International Championship for Makes with the GT40, which still stands today as one of the all-time greatest racing cars. Swiss team Matech GT Racing, in collaboration with Ford Racing, opened a new chapter with the Ford GT, winning the Teams title in the 2008 FIA GT3 European Championship.

The Ford Mustang has arguably been Ford’s most successful sports car. Jerry Titus won the 1965 SCCA Pro B National Championship with a Mustang and the model went on to earn Ford the SCCA Trans-Am Championshiptitle in both 1966 and 1967. Ford won the Trans-Am Championship again in 1970 with Parnelli Jones and George Follmer driving Boss 302 Mustangs for Bud Moore Engineering. Ford took the 1985 and 1986 IMSA GTO Championship with Mustangs driven by John Jones and Scott Pruett before returning to Trans-Am glory with a championship in 1989 with Dorsey Schroeder. Ford dominated Trans-Am in the 1990s with Tommy Kendalwinning championships in 1993, 1995, 1996, and 1997 with Paul Gentilozzi adding yet another title in 1999. In 2005 the Ford Mustang FR500C took the championship in the Rolex Koni Challenge Series in its first year on the circuit. In 2007 Ford added a victory in the GT4 European Championship. 2008 was the first year of the Mustang Challenge for the Miller Cup, a series which pits a full field of identical factory built Ford Mustang race cars against each other. Also in 2008, Ford won the manufacturers championship in the Koni Challenge Series and HyperSport drivers Joe Foster and Steve Maxwell won the drivers title in a Mustang GT.

Touring cars

Ford has campaigned touring cars such as the Focus, Falcon, and Contour/Mondeo and the Sierra Cosworth in many different series throughout the years. Notably, Mondeo drivers finished 1,2,3 in the 2000 British Touring Car Championship and Falcon drivers placed 1,2,3 in the 2005 V8 Supercar Championship Series.

Other

In the Indianapolis 500, Ford powered IndyCars won 17 times between 1965 and 1996. Ford has also branched out into drifting with the introduction of the new model Mustang. Most noticeable is the Turquoise and Blue Falken Tires Mustang driven by Vaughn Gittin Jr, A.K.A. “JR” with 750 RWHP (Rear Wheel Horsepower). In drag racing, John Force Racing drivers John Force, Tony Pedregon, and Robert Hight have piloted Ford Mustang Funny Cars to several NHRA titles in recent seasons. Teammates Tim Wilkerson and Bob Tasca III also drive Mustangs in Funny Car. Formula Ford, a formula for single-seater cars without wings and originally on road tires were conceived in 1966 in the UK as an entry-level formula for racing drivers. Many of today’s racing drivers started their car racing careers in this category.

Environmental initiatives

Compressed natural gas

The alternative fossil fuel vehicles, such as some versions of the Crown Victoria especially in fleet and taxi service, operate on compressed natural gas—or CNG. Some CNG vehicles have dual fuel tanks – one for gasoline, the other for CNG – the same engine can operate on either fuel via a selector switch.

Flexible fuel vehicles

Flexible fuel vehicles are designed to operate smoothly using a wide range of available ethanol fuel mixtures—from pure gasoline, to bioethanol-gasoline blends such as E85 (85% ethanol and 15% gasoline) or E100 (neathydrous ethanol) in Brazil. Part of the challenge of successful marketing alternative and flexible fuel vehicles in the U.S., is the general lack of establishment of sufficient fueling stations, which would be essential for these vehicles to be attractive to a wide range of consumers. Significant efforts to ramp up production and distribution of E85 fuels are underway and expanding. Current Ford E100 Flex sold in the Brazilian market are the Courier, Ford EcoSport, Ford Fiesta, Ford Focus and Ford Ka.

Electric drive vehicles

Hybrid electric vehicles